Preparation method of organosilicone-modified acrylic resin

A technology of acrylic resin and silicone, which is applied in the field of preparation of UV-cured silicone-modified acrylic resin, which can solve the problems of removal and great influence on the degree of polymerization, and achieve the effect of controlling reaction products and simple reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a preparation method of UV-curable silicone-modified acrylic resin A.

[0040] 1. The parts by weight of the reaction raw materials and each raw material are as follows:

[0041] Triethylene glycol dimethacrylate (SR205NS): 100 parts;

[0042] Phenyl hydrogen-containing silicone resin (0.2-0.3% hydrogen content, viscosity 6000-7000mpa.s): 80 parts;

[0043] Platinum catalyst: 0.05 parts;

[0044] 2. The preparation process is as follows:

[0045] (1) Mix triethylene glycol dimethacrylate (SR205NS) and platinum catalyst gold evenly;

[0046] (2) Add phenyl hydrogen-containing silicone resin and stir evenly and heat up to 90 degrees, and react for 3 hours while stirring;

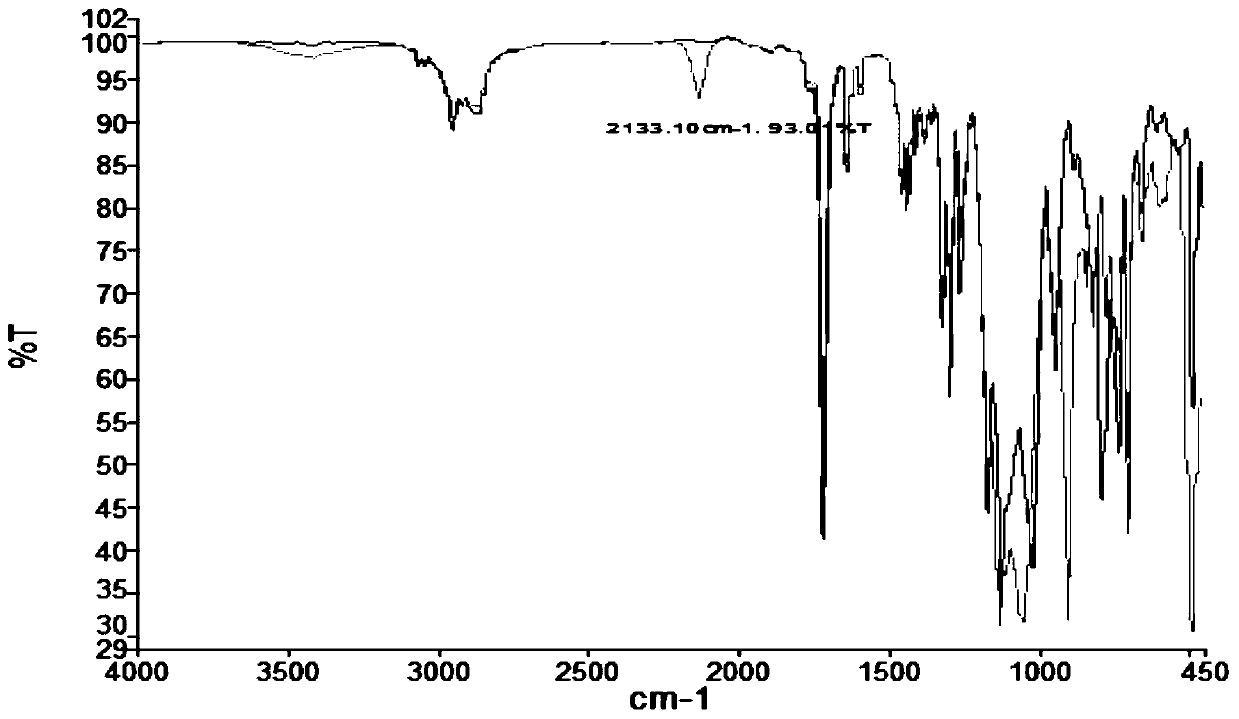

[0047] (3) Infrared detection is used, which is at 2130cm -1 The absorption peak at the (Si—H) position disappears completely, which proves that the reaction is complete, such as figure 1 shown. The reaction was terminated and cooled.

[0048] 3. The reaction formula is ...

Embodiment 2

[0051] This example provides a preparation method of UV-curable silicone-modified acrylic resin B.

[0052] 1. The parts by weight of the reaction raw materials and each raw material are as follows:

[0053] Difunctional aliphatic urethane acrylate oligomer (CN8010NS): 100 parts;

[0054] Phenyl hydrogen-containing silicone resin (0.2-0.3% hydrogen content, viscosity 6000-7000mpa.s): 80 parts;

[0055] Platinum catalyst: 0.05 parts;

[0056] 2. The preparation process is as follows:

[0057] (1) Bifunctional aliphatic urethane acrylate (CN8010NS) and platinum catalyst gold are mixed evenly;

[0058] (2) Add phenyl hydrogen-containing silicone resin and stir evenly and heat up to 90 degrees, and react for 3 hours while stirring;

[0059] (3) The reaction is terminated and cooled.

Embodiment 3

[0061] This embodiment provides a preparation method of UV-curable silicone-modified acrylic resin C.

[0062] 1. The parts by weight of the reaction raw materials and each raw material are as follows:

[0063] Triethylene glycol dimethacrylate (SR205NS): 50 parts;

[0064] Difunctional aliphatic urethane acrylate oligomer (CN8010NS): 50 parts;

[0065] Phenyl hydrogen-containing silicone resin (0.2-0.3% by mass of hydrogen, viscosity 6000-7000mpa.s): 60 parts;

[0066] Platinum catalyst: 0.045 parts;

[0067] 2. The preparation process is as follows:

[0068] (1) Mix triethylene glycol dimethacrylate (SR205NS), difunctional aliphatic urethane acrylate oligomer (CN8010NS) and platinum catalyst gold evenly;

[0069] (2) Add phenyl hydrogen-containing silicone resin, stir evenly and heat up to 90 degrees, and react for 4 hours while stirring;

[0070] (3) The reaction is terminated and cooled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com