Multifunctional negative-ion dry powder paint

A dry powder coating and negative ion powder technology, applied in the coating field, can solve the problems of less released negative ions, low hardness, poor water washing resistance, etc., and achieve the effects of increasing adjustment ability, strong moisture releasing ability, and strong moisture absorption ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

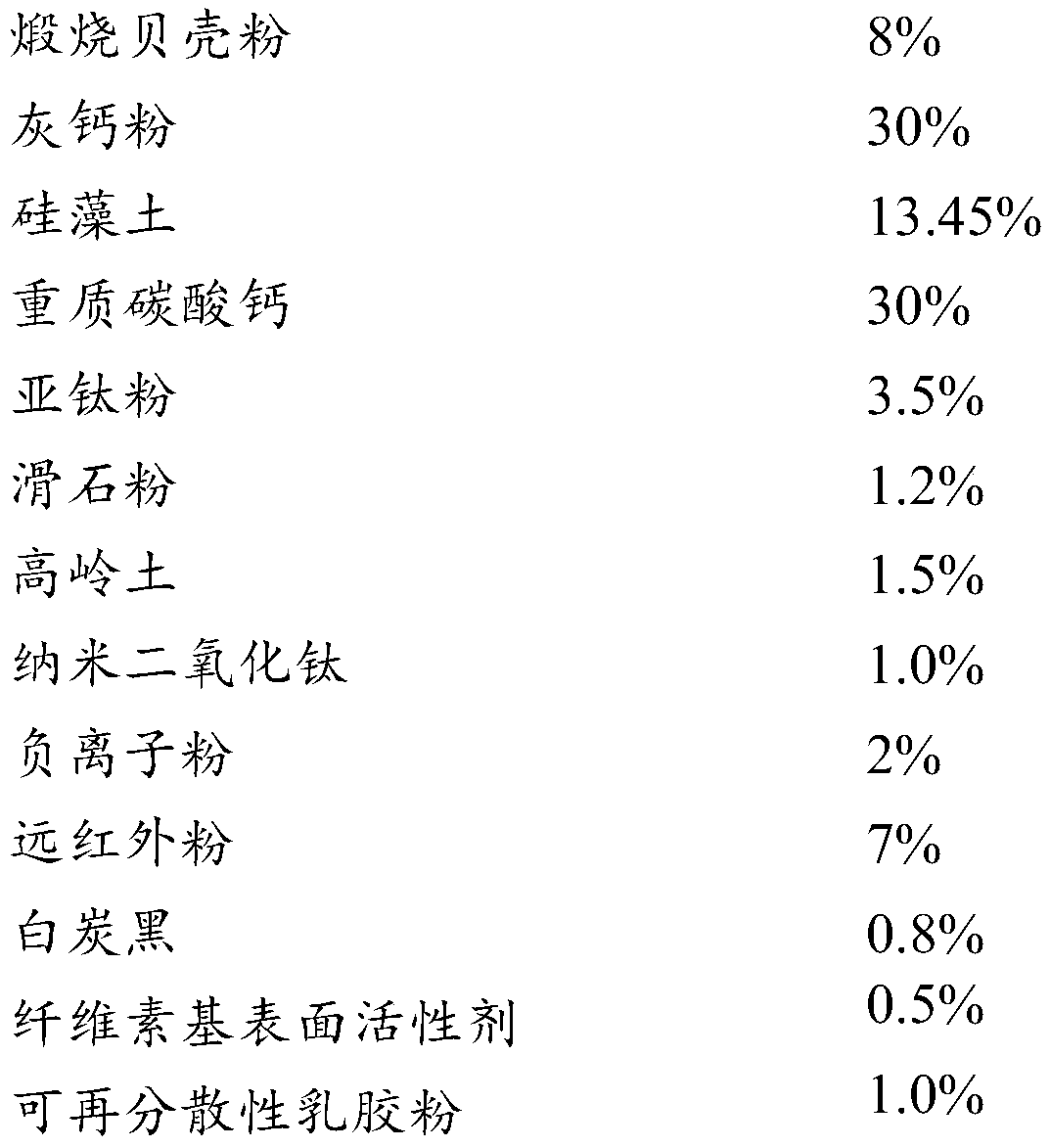

Embodiment 1

[0073] Weigh 8 kg of calcined shell powder, 30 kg of gray calcium powder, 13.45 kg of diatomite, 30 kg of heavy calcium carbonate, 3.5 kg of titanium dioxide powder, 1.2 kg of talcum powder, 1.5 kg of kaolin, 1.0 kg of nano-titanium dioxide, 2 kg Negative ion powder (Dongguan Yanteng Negative Ion Technology Co., Ltd., model YT-W001, release 38000 / cm 3 ), 7 kilograms of far-infrared powder, 0.8 kilograms of white carbon black, 0.5 kilograms of sodium carboxymethyl cellulose, 1.0 kilograms of acrylic acid rubber powder and 0.05 kilograms of imported Dutch Aiweibei potato starch ether S301, with a paint grinder (Anhui Huapai Chemical Industry Co., Ltd. Equipment Co., Ltd.) grind each component to more than 1600 mesh, and then add the powder into a commonly used paint mixer and stir for 15-30 minutes until it is uniform to prepare a multifunctional anion dry powder paint.

Embodiment 2

[0075] Weigh 10 kg of calcined shell powder, 28 kg of gray calcium powder, 13.45 kg of diatomite, 30 kg of heavy calcium carbonate, 3.5 kg of titanium dioxide powder, 1.2 kg of talcum powder, 1.5 kg of kaolin, 1.0 kg of nano-titanium dioxide, 2 kg Negative ion powder (Dongguan Yanteng Negative Ion Technology Co., Ltd., model YT-W001, release 38000 / cm 3 ), 7 kilograms of far-infrared powder, 0.8 kilograms of white carbon black, 0.5 kilograms of hydroxyethyl cellulose, 1.0 kilograms of styrene-butadiene rubber powder and 0.05 kilograms of imported Holland Aiweibei potato starch ether S301, with a coating grinder (Anhui Huapai Chemical Industry Co., Ltd. Equipment Co., Ltd.) grind each component to more than 1600 mesh, and then add the powder into a commonly used paint mixer and stir for 15-30 minutes until it is uniform to prepare a multifunctional anion dry powder paint.

Embodiment 3

[0077] Weigh 12 kg of calcined shell powder, 28 kg of gray calcium powder, 13.45 kg of diatomite, 28 kg of heavy calcium carbonate, 3.5 kg of titanium dioxide powder, 1.2 kg of talcum powder, 1.5 kg of kaolin, 1.0 kg of nano-titanium dioxide, 2 kg Negative ion powder (Dongguan Yanteng Negative Ion Technology Co., Ltd., model YT-W001, release 38000 / cm 3 ), 7 kg of far-infrared powder, 0.8 kg of white carbon black, 0.5 kg of hydroxypropyl methylcellulose, 1.0 kg of ethylene-vinyl acetate copolymer rubber powder and 0.05 kg of imported Dutch Aiweibe potato starch ether S301, ground with paint Machine (Anhui Huapai Chemical Equipment Co., Ltd.) grinds each component to more than 1600 mesh, and then adds the powder into a commonly used paint mixer and stirs for 15-30 minutes until it is uniform to prepare a multifunctional anion dry powder paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com