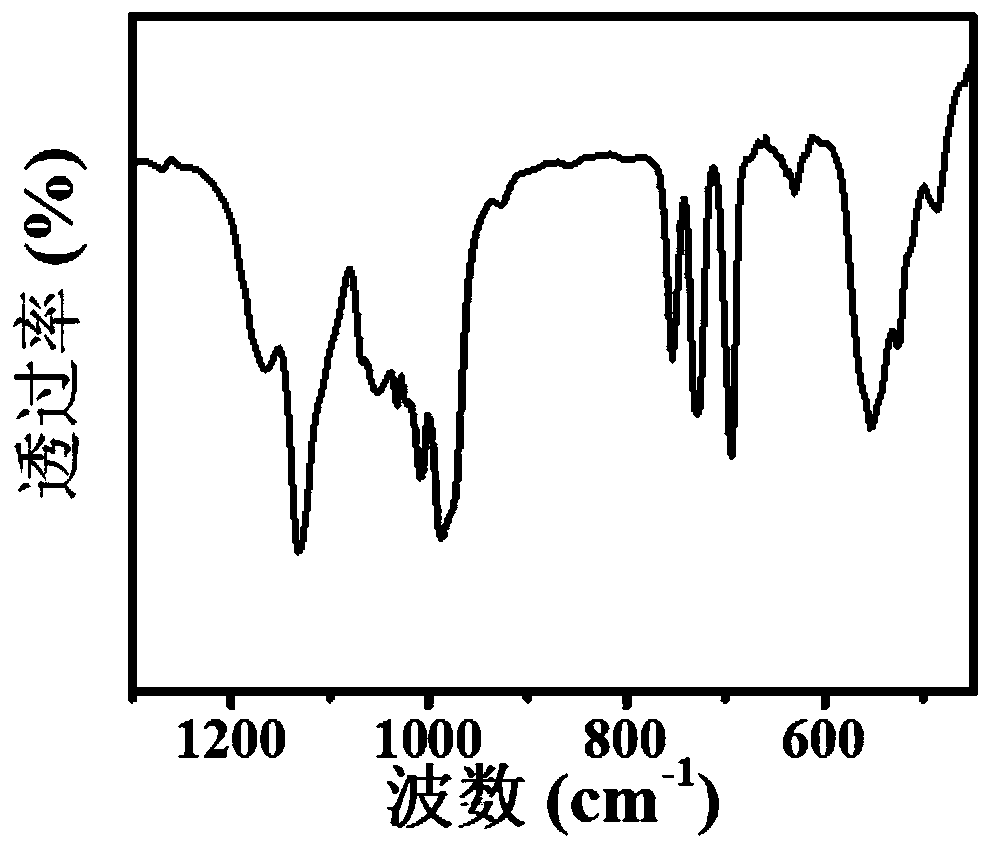

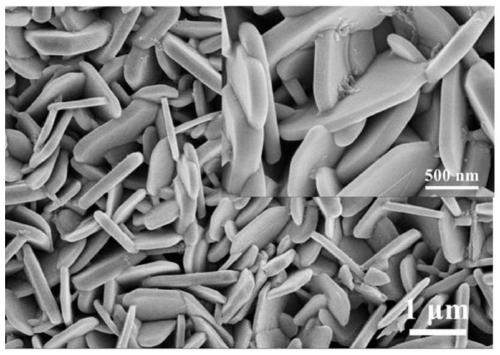

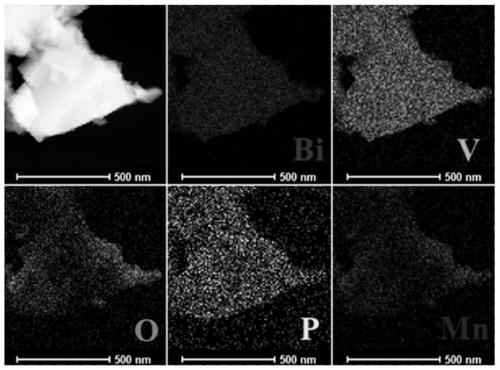

A composite bismuth vanadate photoelectrode comprising a bionic manganese-core cubane catalyst and a preparing method thereof

A technology of bismuth vanadate and cubane, which is applied in the field of biomimetic manganese nuclear cubane catalyst composite bismuth vanadate photoelectrode and its preparation, can solve the problems of high reaction overpotential and slow reaction kinetics, and achieve broad application prospects, current High density, the effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of bismuth vanadate seed layer: Weigh 0.41 g of bismuth nitrate and 0.365 g of ethylenediaminetetraacetic acid and disperse in 15 ml of deionized water, add 1 ml of ammonia water to adjust the pH, stir until the powder dissolves, and prepare A solution. Weigh 0.1 g of ammonium metavanadate and 0.0913 g of ethylenediaminetetraacetic acid and disperse them in 15 ml of deionized water, add 1 ml of ammonia water to adjust the pH, stir until the powder dissolves, and prepare solution B. The solution A and the solution B are evenly mixed to obtain a seed layer precursor. Take the FTO conductive glass for spin coating, 10 drops each time, spin coating 3 times, and keep warm at 500 °C for 10 min after each spin coating. After the spin coating was completed, the FTO conductive glass was placed in the air atmosphere and calcined at 500 °C for 2 h to obtain a bismuth vanadate seed layer.

[0033] (2) Preparation of bismuth vanadate photoelectrode: Weigh 0.1455 g o...

Embodiment 2

[0041](1) Preparation of bismuth vanadate seed layer: Weigh 0.41 g of bismuth nitrate and 0.365 g of ethylenediaminetetraacetic acid and disperse in 15 ml of deionized water, add 1 ml of ammonia water to adjust the pH, stir until the powder dissolves, and prepare A solution. Weigh 0.1 g of ammonium metavanadate and 0.0913 g of ethylenediaminetetraacetic acid and disperse them in 15 ml of deionized water, add 1 ml of ammonia water to adjust the pH, stir until the powder dissolves, and prepare solution B. The solution A and the solution B are evenly mixed to obtain a seed layer precursor. Take the FTO conductive glass for spin coating, 10 drops each time, spin coating 3 times, and keep warm at 500 °C for 10 min after each spin coating. After the spin coating was completed, the FTO conductive glass was placed in the air atmosphere and calcined at 500 °C for 2 h to obtain a bismuth vanadate seed layer.

[0042] (2) Preparation of bismuth vanadate photoelectrode: Weigh 0.1455 g of...

Embodiment 3

[0050] (1) Preparation of bismuth vanadate seed layer: Weigh 0.41 g of bismuth nitrate and 0.365 g of ethylenediaminetetraacetic acid and disperse in 15 ml of deionized water, add 1 ml of ammonia water to adjust the pH, stir until the powder dissolves, and prepare A solution. Weigh 0.1 g of ammonium metavanadate and 0.0913 g of ethylenediaminetetraacetic acid and disperse them in 15 ml of deionized water, add 1 ml of ammonia water to adjust the pH, stir until the powder dissolves, and prepare solution B. The solution A and the solution B are evenly mixed to obtain a seed layer precursor. Take the FTO conductive glass for spin coating, 10 drops each time, spin coating 3 times, and keep warm at 500 °C for 10 min after each spin coating. After the spin coating was completed, the FTO conductive glass was placed in the air atmosphere and calcined at 500 °C for 2 h to obtain a bismuth vanadate seed layer.

[0051] (2) Preparation of bismuth vanadate photoelectrode: Weigh 0.1455 g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com