Preparation method of X-ray and gamma-ray shielding composite fiber

A composite fiber and γ-ray technology, applied in the field of radiation protection, can solve the problems of poor mechanical properties of materials, low X-ray shielding rate, and poor durability, and achieve the effects of good durability, simple process flow, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

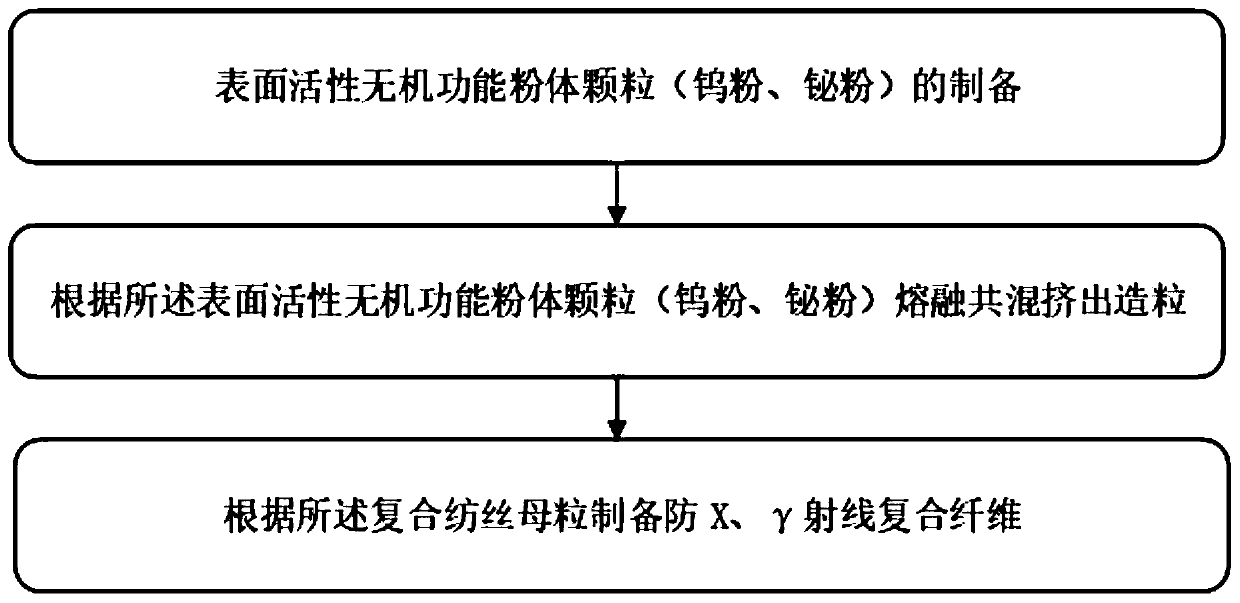

[0031] Prepare as follows:

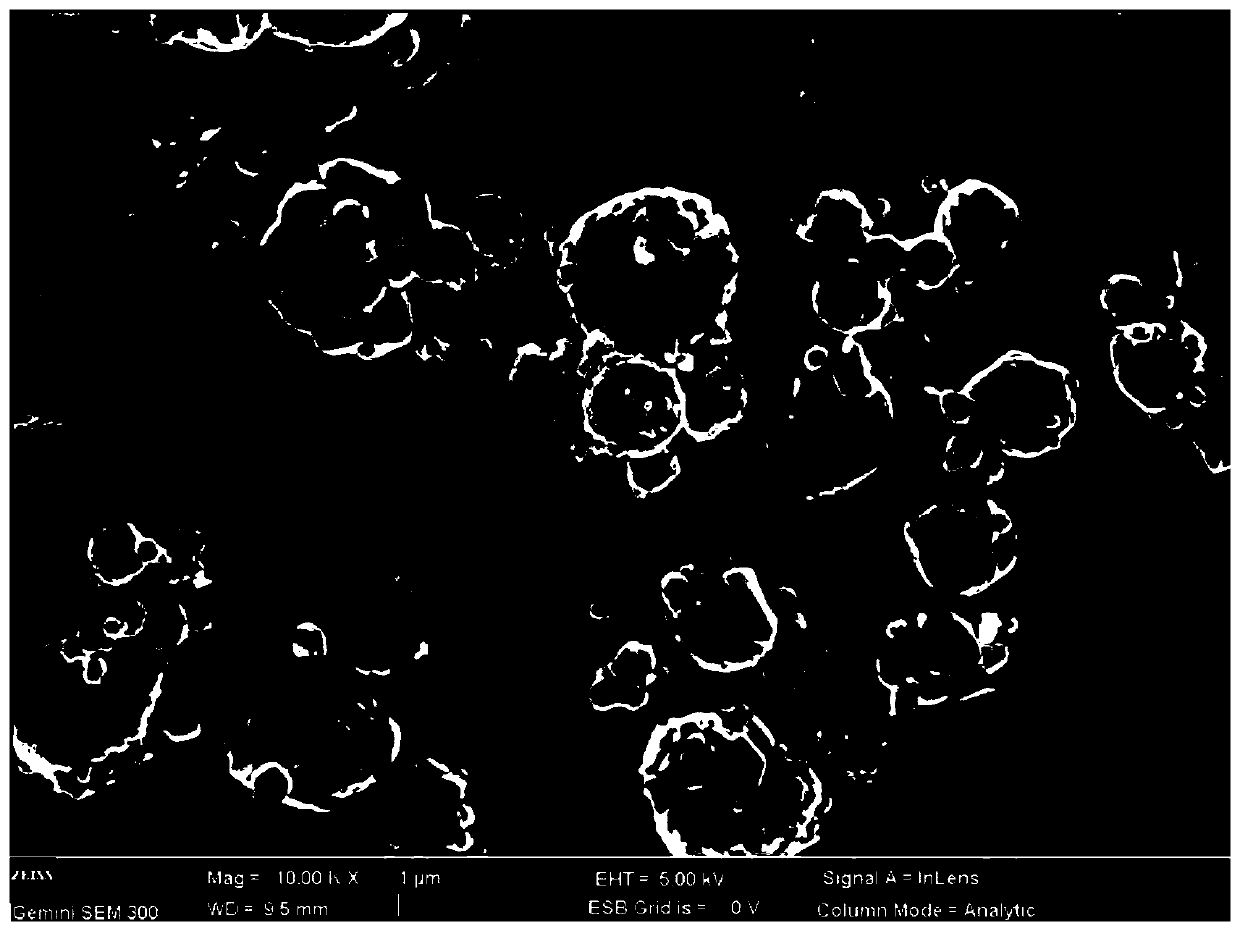

[0032] (1) Preparation of surface-active inorganic ray-shielding functional bismuth powder particles: at room temperature, prepare surface-active bismuth powder filler treatment according to mass percent dehydrated alcohol 89%, deionized water 10%, octa(aminophenyltrioxysilane) 1% Add an appropriate amount of oxalic acid to adjust the pH to 3.5-4, and then magnetically stir until the solution is clear and transparent; then add bismuth powder particles equivalent to 50 times the mass of octa(aminophenyltrioxysilane) and an average particle size of 1 μm into the solution In the process, stir magnetically for 30 minutes, then oscillate ultrasonically for 30 minutes, then use deionized water to wash twice and then transfer to an evaporating dish. Finally, put the evaporating dish in a blast drying oven and dry it at 75°C for 6 hours to obtain a surface-active inorganic radiation-shielding functional powder. Bismuth powder particles.

[0033] (2) Blend...

Embodiment 2

[0037] Prepare as follows:

[0038] (1) Preparation of surface-active inorganic ray-shielding function bismuth powder particles: at room temperature, prepare surface-active bismuth powder filler treatment according to mass percent dehydrated alcohol 78%, deionized water 20%, octa(aminophenyltrioxysilane) 2% Add an appropriate amount of oxalic acid to adjust the pH to 3.5-4, and then magnetically stir until the solution is clear and transparent; then add bismuth powder particles equivalent to 100 times the mass of octa(aminophenyltrioxysilane) and an average particle size of 1 μm into the solution In the process, stir magnetically for 30 minutes, then oscillate ultrasonically for 30 minutes, then use deionized water to wash twice and then transfer to an evaporating dish. Finally, put the evaporating dish in a blast drying oven and dry it at 75°C for 6 hours to obtain a surface-active inorganic radiation-shielding functional powder. Bismuth powder particles.

[0039] (2) Blendi...

Embodiment 3

[0042] Prepare as follows:

[0043] (1) Preparation of surface-active inorganic ray-shielding function bismuth powder particles: at room temperature, prepare surface-active bismuth powder filler treatment according to mass percent absolute ethanol 89.7%, deionized water 10%, octa(aminophenyltrioxysilane) 0.3% Add an appropriate amount of oxalic acid to adjust the pH to 3.5-4, and then magnetically stir until the solution is clear and transparent; then add bismuth powder particles equivalent to 50 times the mass of octa(aminophenyltrioxysilane) and an average particle size of 1 μm into the solution In the process, stir magnetically for 30 minutes, then oscillate ultrasonically for 30 minutes, then use deionized water to wash twice and then transfer to an evaporating dish. Finally, put the evaporating dish in a blast drying oven and dry it at 75°C for 6 hours to obtain a surface-active inorganic radiation-shielding functional powder. Bismuth powder particles.

[0044] (2) Blend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com