Surface-modified cyano-based framework material, preparation method and application thereof

A frame material and surface modification technology, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of unstable structure, easy to be corroded by electrolyte, etc., achieve low cost, improve cycle stability, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

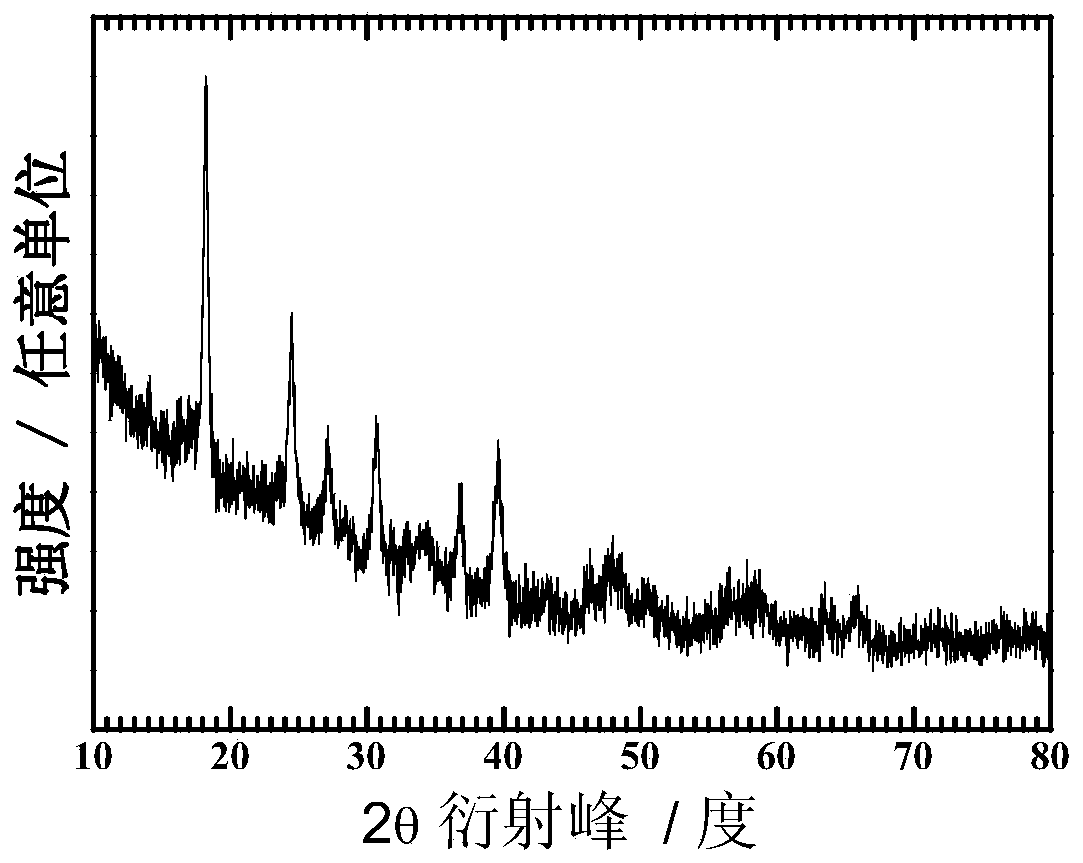

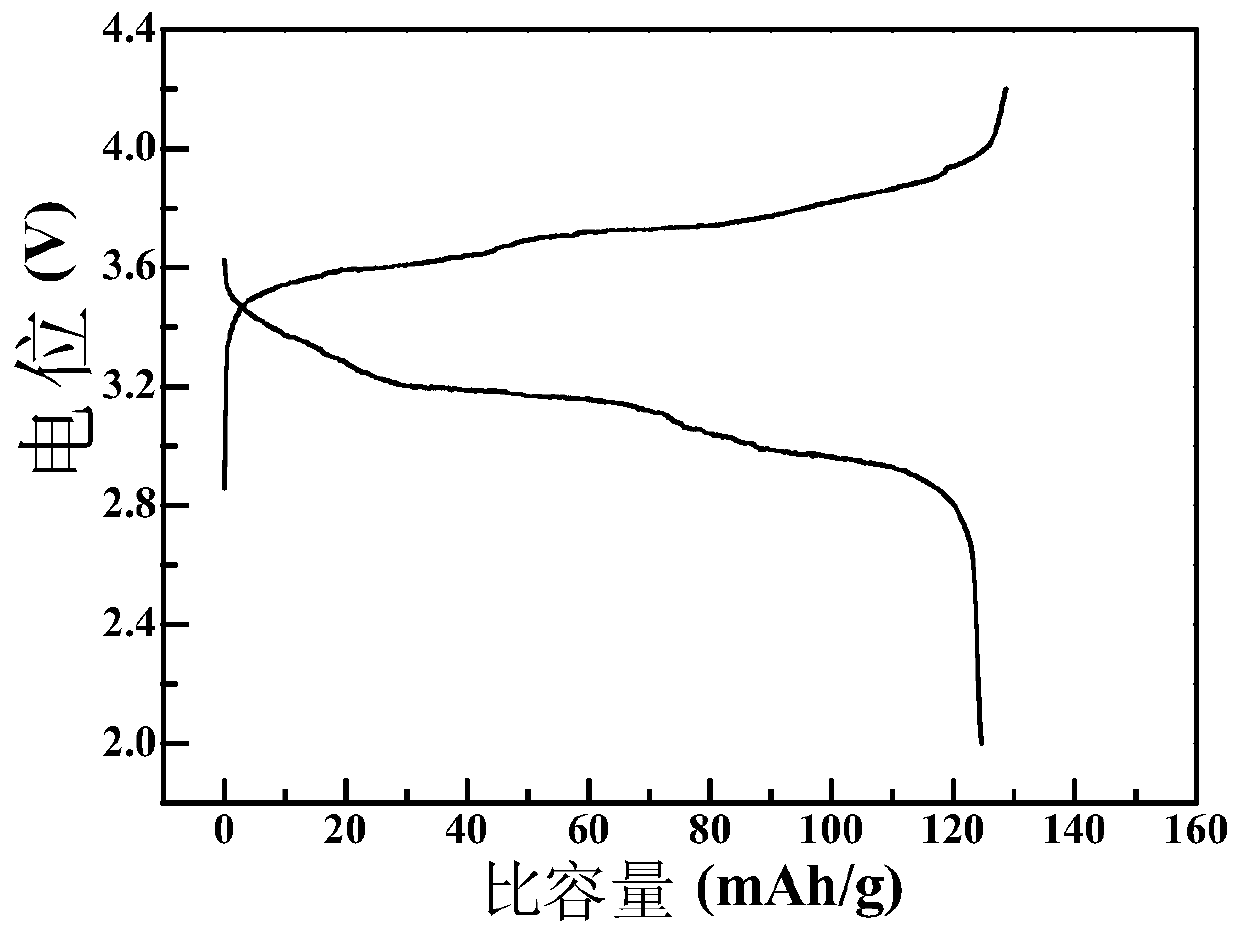

Embodiment 1

[0038] Dissolve sodium ferrocyanide decahydrate in 1 liter of deionized water, and stir evenly to obtain solution I with a concentration of 0.5 mol / L in terms of ferrocyanide ion; dissolve manganese sulfate and zinc acetate in 1 liter of deionized water , get Mn 2+ Count and Zn 2+ The solutions with the concentration of 0.495mol / L and 0.055mol / L were obtained by fully stirring to obtain solution II; sodium chloride was dissolved in 1 liter of deionized water to obtain solution III with a concentration of 5mol / L; then, under constant stirring , Add solution I and solution II to solution III at the same time, and obtain a suspension by co-precipitation at 85°C; then add 1.1 liters of 0.1mol / L sodium hydroxide solution to the above suspension, and then cool and wash , separation, and vacuum drying to obtain the ZnO-coated cyano-based framework material Na x mn 0.99 Zn 0.01 Fe(CN) 6 , where the molar mass of ZnO is the same as that of Na x mn 0.99 Zn 0.01 Fe(CN) 6 The mol...

Embodiment 2

[0047] Dissolve sodium ferrocyanide decahydrate in 1 liter of deionized water, and stir evenly to obtain solution I with a concentration of 0.1 mol / L in terms of ferrocyanide ion; dissolve manganous chloride and magnesium acetate in 1 liter of deionized water In water, get Mn 2+ Calculated and in Mg 2+ The solutions with the concentration of 0.09mol / L and 0.015mol / L were obtained by fully stirring to obtain solution II; sodium chloride was dissolved in 1 liter of deionized water to obtain solution III with a concentration of 5mol / L; then, under constant stirring , Add solution I and solution II to solution III at the same time, and obtain a suspension through co-precipitation reaction at 85°C; then add 0.105 liters of 0.1mol / L sodium hydroxide solution to the above suspension, and then cool and wash , separation, and vacuum drying to obtain the MgO-coated cyano-based framework material Na x mn 0.9 Mg 0.1 Fe(CN) 6 , where the molar mass of MgO is the same as that of Na x ...

Embodiment 3

[0049] Dissolve sodium ferrocyanide decahydrate in 1 liter of deionized water, and stir evenly to obtain a solution I with a concentration of 0.2 mol / L in terms of ferrocyanide ion; dissolve manganous nitrate and copper acetate in 1 liter of deionized water , get Mn 2+ Calculate and take Cu 2+ The concentration is respectively 0.19mol / L and the solution of 0.04mol / L, obtains solution II through thorough stirring; Sodium chloride is dissolved in 1 liter of deionized water, obtains the solution III that concentration is 5mol / L; Then under constant stirring , Add solution I and solution II to solution III at the same time, and obtain a suspension through co-precipitation reaction at 85°C; then add 0.69 liters of 0.1mol / L sodium hydroxide solution to the above suspension, and then cool and wash , separation, and vacuum drying to obtain the CuO-coated cyano-based framework material Na x mn 0.95 Cu 0.05 Fe(CN) 6 , where the molar mass of CuO is the same as that of Na x mn 0.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com