Preparation method of high-activity diesel particulate filter (DPF) coating capable of simultaneously removing NOx and PM

A DPF, high-activity technology, applied in the field of preparation of high-activity DPF coatings, can solve the problems of damage to the carrier, increase economic costs, etc., and achieve the effects of low preparation costs, reduced economic costs, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

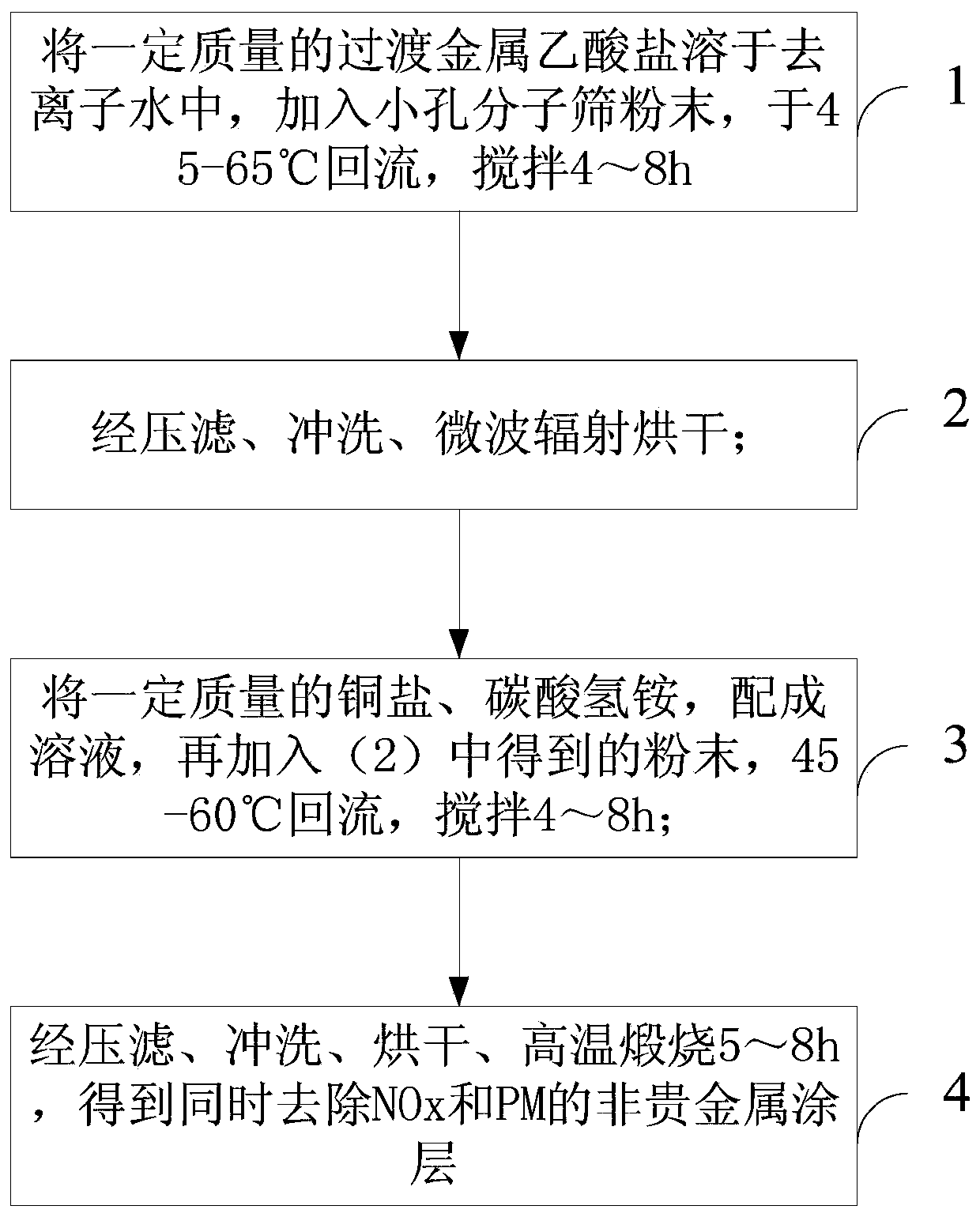

Method used

Image

Examples

Embodiment 1

[0020] (1) Dissolve 51g of cerium acetate weighed in 2500g of deionized water, add 2000g of small-pore molecular sieve powder SSZ-13, reflux at 45°C, and stir for 8h;

[0021] (2) After press filtration, washing twice, and 1000HZ microwave radiation drying;

[0022] (3) Weigh 17g of copper acetate and 1g of ammonium bicarbonate to make a solution, then add the powder obtained in (2), reflux at 45°C, and stir for 8h;

[0023] (4) After pressure filtration, washing, drying at 105°C, and high-temperature calcination for 5 hours, a non-precious metal coating that simultaneously removes NOx and PM is obtained.

Embodiment 2

[0025] (1) Dissolve 48g of cobalt acetate weighed in 2600g of deionized water, add small-pore molecular sieve powder 1800g Sapo-34, reflux at 65°C, and stir for 4h;

[0026] (2) After press filtration, washing twice, and 1200HZ microwave radiation drying;

[0027] (3) Weigh 20g of copper nitrate and 0.8g of ammonium bicarbonate to form a solution, then add the powder obtained in (2), reflux at 60°C, and stir for 4h;

[0028] (4) After pressure filtration, washing, drying at 105°C, and high-temperature calcination for 8 hours, a non-precious metal coating that simultaneously removes NOx and PM is obtained.

Embodiment 3

[0030] (1) Dissolve 56g of lanthanum acetate in 2800g of deionized water, add small-pore molecular sieve powder 800g Sapo-34 and 800g SSZ-13, reflux at 60°C, and stir for 4 hours;

[0031] (2) After press filtration, washing twice, and 1200HZ microwave radiation drying;

[0032] (3) Weigh 22g of copper acetate and 1.3g of ammonium bicarbonate to make a solution, then add the powder obtained in (2), reflux at 60°C, and stir for 4h;

[0033] (4) After pressure filtration, rinsing, drying at 105°C, and high-temperature calcination for 6 hours, a non-precious metal coating that simultaneously removes NOx and PM is obtained.

[0034] It should be noted that, in other embodiments,

[0035] It is also feasible to adopt certain two combinations in cerium acetate, cobalt acetate and lanthanum acetate in step (1);

[0036] It is also feasible to adopt the combination of copper acetate and copper nitrate in step (3).

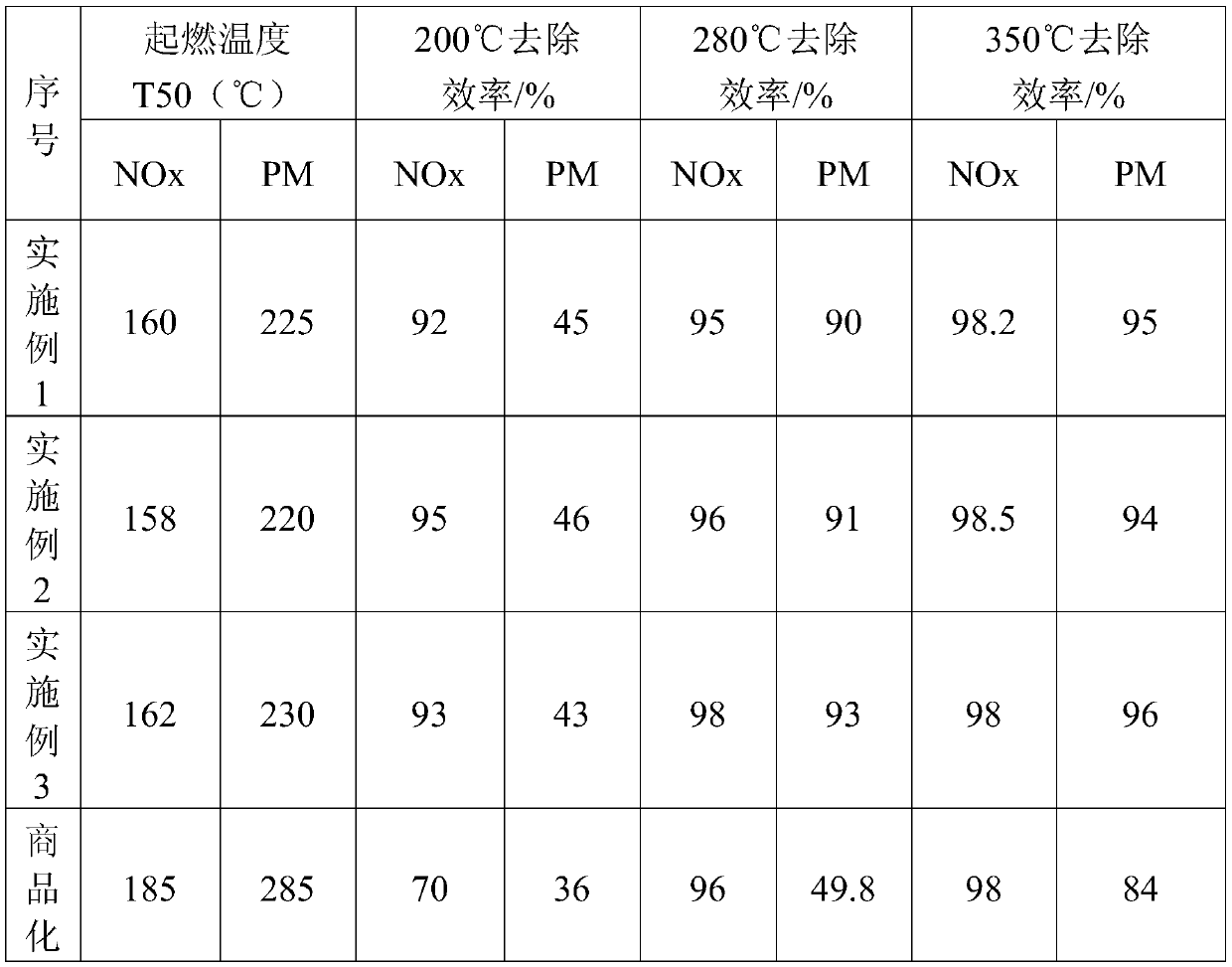

[0037] Table 1

[0038] Example Specific surface area / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com