Coating having both luminous and fluorescent properties, and preparation method thereof

A fluorescent performance and coating technology, which is applied in the direction of luminescent coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of short luminous life, etc., and achieve good adhesion, environmental friendliness, and obvious luminous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of coating with luminous and fluorescent properties, by weight percentage, the coating comprises the following components: 3% of carbon dot fluorescent material, 3% of organic long-lasting luminescent material, 27% of organosilicon modified water-based polyurethane emulsion, pigment ( Hollow ceramic nanoparticles 4.5%, silica airgel 4.5%, graphene airgel 4.5%, sericite 4.5%, polypyrrole 4.5%, zinc vanadate microspheres 4.5%) 27%, filler (barium sulfate) 9%, wetting and dispersing agent (Hydropalat 5040) 0.9%, defoamer (BYK-028) 0.9%, leveling agent (BYK-420) 0.45%, thickener (sodium carboxymethylcellulose) 1.25%, Coalescing aid (TexanolOE-300) 3.0%, balance is water. The coating is prepared as follows:

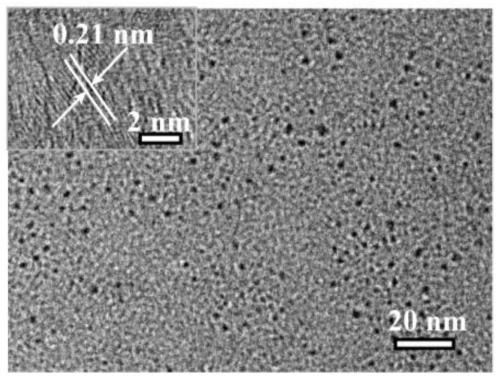

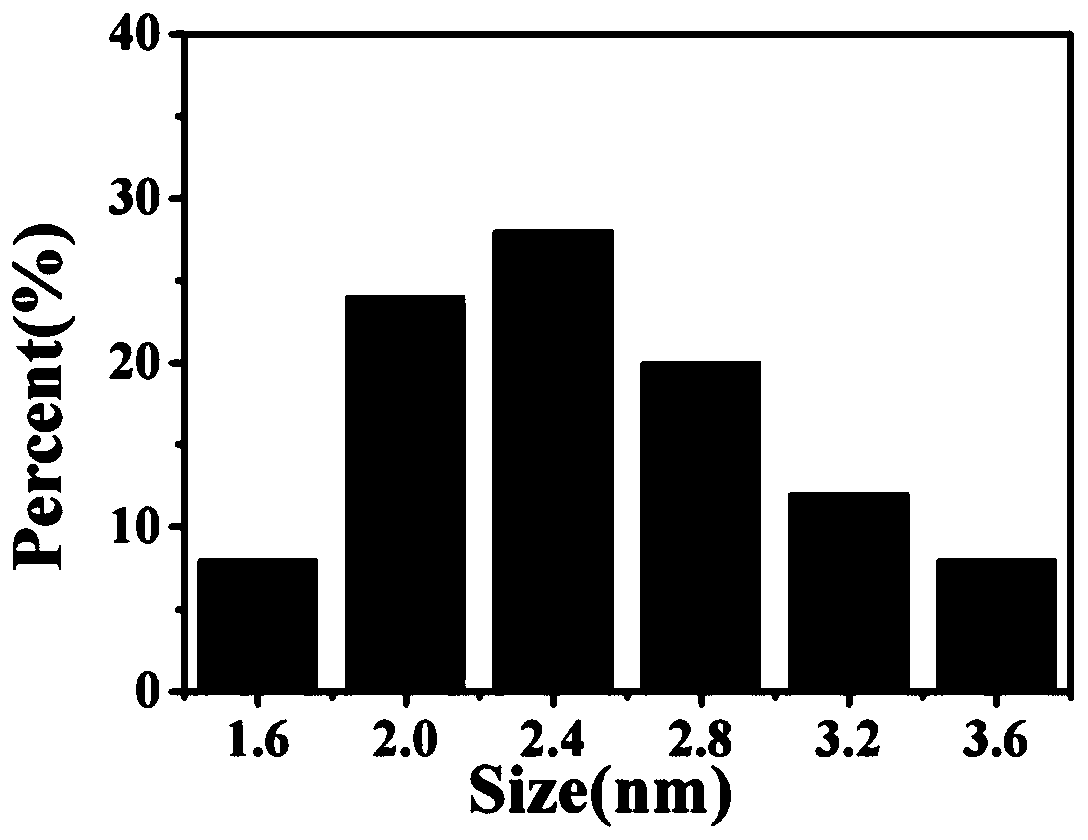

[0032] (1) Put the 2,5-diaminopyridine aqueous solution with a mass fraction of 20% in the high-temperature-resistant polytetrafluoroethylene reactor liner, and then put it into the supporting iron reactor shell, hydrothermally treat it at 180 ° C for 5 hours, a...

Embodiment 2

[0038] A kind of coating with luminous and fluorescent properties, by weight percentage, the coating comprises the following components: 2% of carbon dot fluorescent material, 4.5% of organic long-lasting luminescent material, 45% of silicone modified water-based polyurethane emulsion, pigment ( Hollow ceramic nanoparticles 9%, silica airgel 6%, graphene airgel 4.5%, sericite 4.5%, polypyrrole 4%, zinc vanadate microspheres 8%) 36%, filler (barium sulfate 6 %, calcium carbonate 6%) 12%, wetting and dispersing agent (Dispersogen 4387) 0.5%, defoamer (EFKA-2526) 0.4%, leveling agent (BYK-428) 0.2%, thickener (hydroxyethyl Cellulose) 1.8%, coalescence aid (DOWANOL TPnB) 2%, balance is water. The coating is prepared as follows:

[0039] (1) Put the 2,5-diaminopyridine aqueous solution with a mass fraction of 25% in the high-temperature-resistant polytetrafluoroethylene reactor liner, then put it into the supporting iron reactor shell, hydrothermally treat it at 170 ° C for 8 hour...

Embodiment 3

[0045] A kind of coating with both luminous and fluorescent properties, by weight percentage, the coating comprises the following components: 1% of carbon dot fluorescent material, 1% of organic long-lasting luminescent material, 35% of silicone modified water-based polyurethane emulsion, pigment ( Hollow ceramic nanoparticles 9%, sericite 4.5%, zinc vanadate microspheres 4.5%) 18%, filler (barium sulfate 12%, calcium carbonate 6%) 18%, wetting and dispersing agent (Disperbyk-184) 0.2%, Defoamer (SurfynolDF-60) 0.2%, leveling agent (BYK-425) 0.1%, thickener (xanthan gum) 0.45%, film-forming aid (SER-AD FX 510) 1%, the balance is water. The coating is prepared as follows:

[0046] (1) Put the 2,5-diaminopyridine aqueous solution with a mass fraction of 15% in the high-temperature-resistant polytetrafluoroethylene reactor inner tank, and then put it into the supporting iron reactor shell, hydrothermally treat it at 190 ° C for 3 hours, and then Put the reaction solution into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com