Preparation method of molybdenum disulfide nanosheet

A technology of nano-sheets and molybdenum disulfide, applied in the fields of chemistry and materials, can solve problems that are not conducive to the preparation and application of molybdenum disulfide, randomness, or high requirements for reaction conditions, and achieve high repeatability, low cost, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

[0073] Embodiment 1 molybdenum disulfide nano flake material sample 1 # preparation of

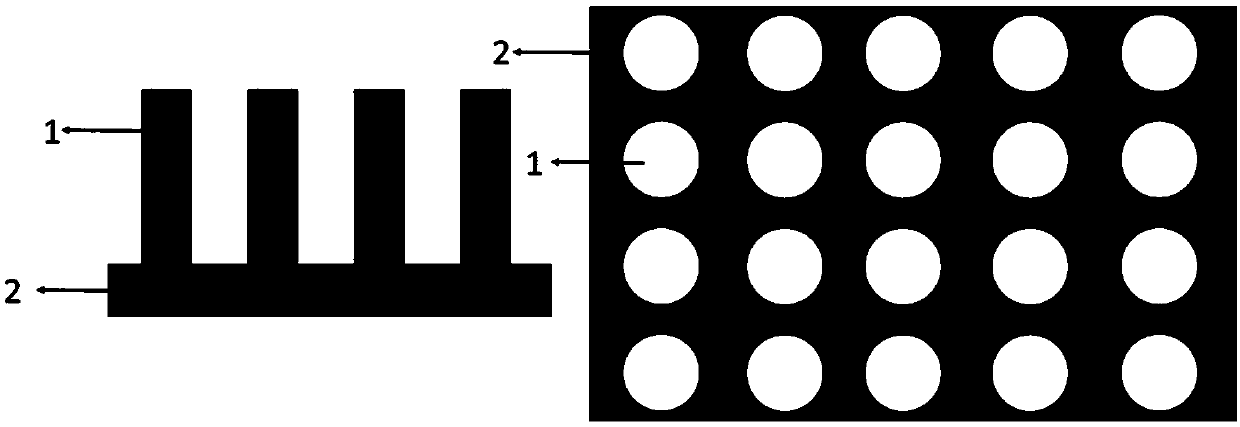

[0074] Will figure 1 and figure 2 The gallium nitride substrate with nanopillars shown in the figure was put into a beaker, and 40mL of hydrochloric acid was added to the beaker, the beaker was sealed, and the beaker was placed in an ultrasonic cleaner and cleaned for 10 minutes at a power of 40W; Wash with absolute ethanol for 10 minutes at a power of 40W; finally take it out, dry the absolute ethanol on the surface of the gallium nitride substrate with nanopillars, and place it face up on the filter paper.

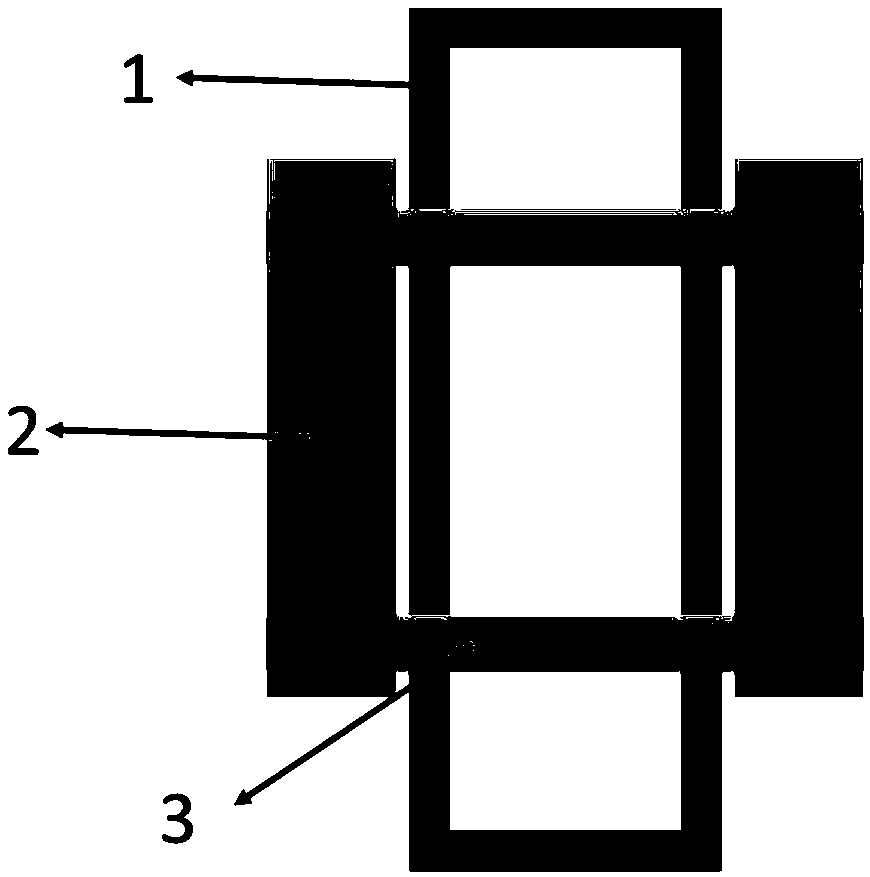

[0075] Put 0.1g of molybdenum trioxide powder in a quartz boat with a height of 2cm, and use a silicon wafer with a thickness of 1 micron to image 3 The gallium nitride substrate with nanopillars is set up in a well shape, the substrate is face down, and it is put into the tube furnace from the right side. Put 1g of sulfur powder in another quartz boat with a height of 2cm, and...

Embodiment 2 2

[0077] Embodiment 2 molybdenum disulfide nano flake material sample 2 # preparation of

[0078] The present embodiment keeps the same preparation conditions as in Example 1, except that:

[0079] The amount of raw materials is: 0.1g molybdenum trioxide, 0.8g sulfur powder; the gallium nitride substrate with nanopillars is facing up; the nitrogen flow rate is adjusted to 100 sccm; a glass sheet with a thickness of 5 microns is used as a gasket; the sulfur powder is heated to 150°C, heat molybdenum trioxide to 810°C; the prepared molybdenum disulfide nanosheet material is denoted as 2 # sample.

Embodiment 3 2

[0080] The characterization of embodiment 3 molybdenum disulfide nano-flake material sample

[0081] with 1 # The sample is typical, and the scanning electron microscope, Raman spectrum and fluorescence spectrum were tested for molybdenum disulfide.

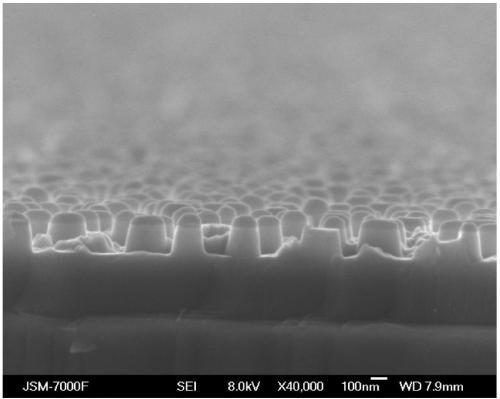

[0082] Figure 5 for sample 1 # Scanning electron micrograph of molybdenum disulfide nanosheets, as can be seen from the figure, sample 1 # The molybdenum disulfide is a dense vertical sheet of nano-flakes, the size of which is 180-1000nm in height and 0.8-50nm in thickness; the density of nano-flakes is 1-10 pieces per square micron.

[0083] Figure 6 is 1 # The Raman spectrum of the sample molybdenum disulfide nano-flakes. It can be seen from the figure that the peak position difference between the two Raman peaks of the molybdenum disulfide flakes is about 26cm -1 .

[0084] Figure 7 is 1 # The fluorescence spectrum of the sample molybdenum disulfide nano-flakes. It can be seen from the figure that the fluorescence ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com