Lead-removal nontoxic environment-friendly PVC (polyvinyl chloride) profile raw material formula and preparation method

A non-toxic and environmentally friendly, PVC resin technology, applied in the field of building materials, can solve the problems of polluting the environment, failing to achieve, and failing to achieve environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

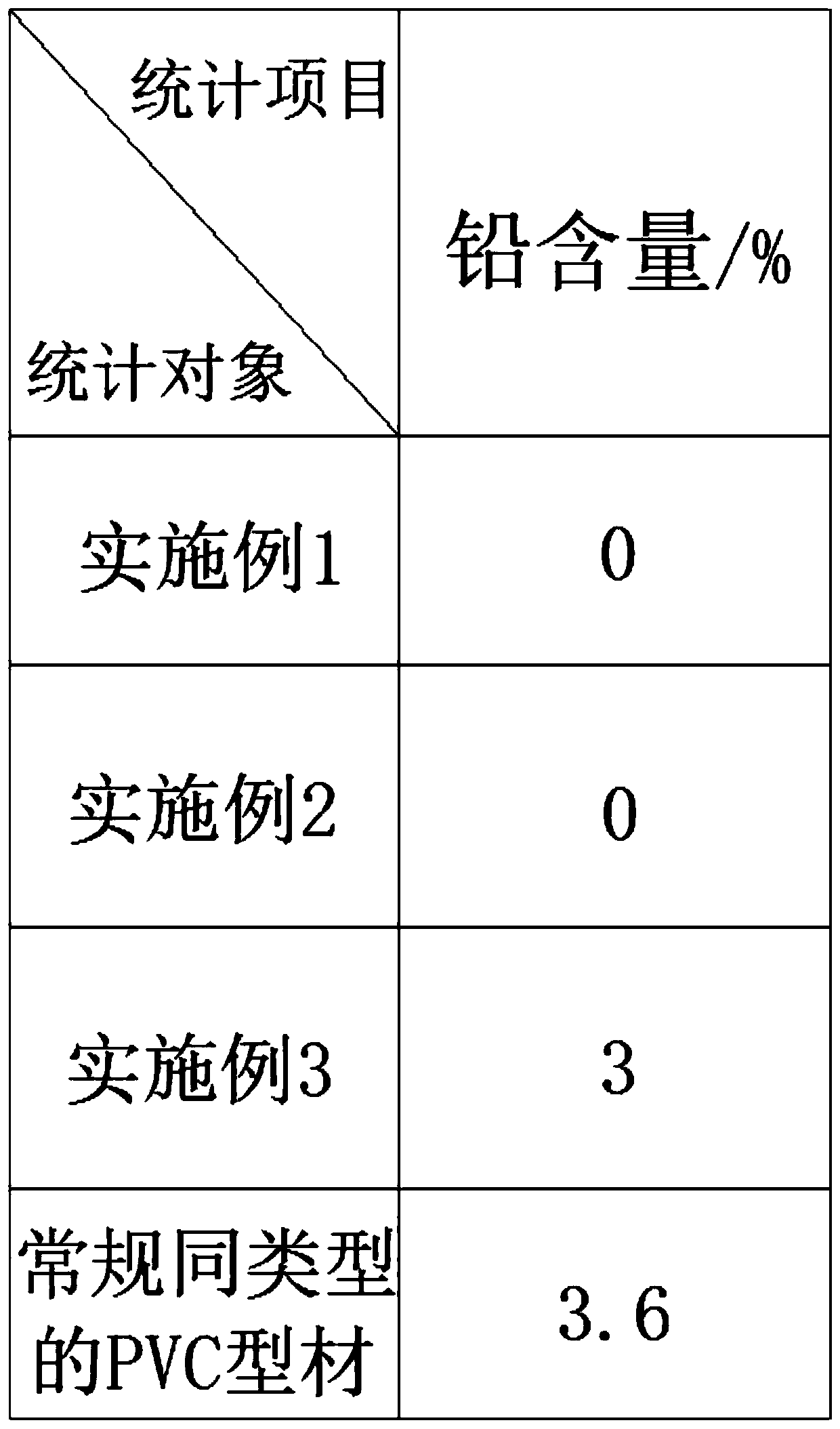

Examples

Embodiment 1

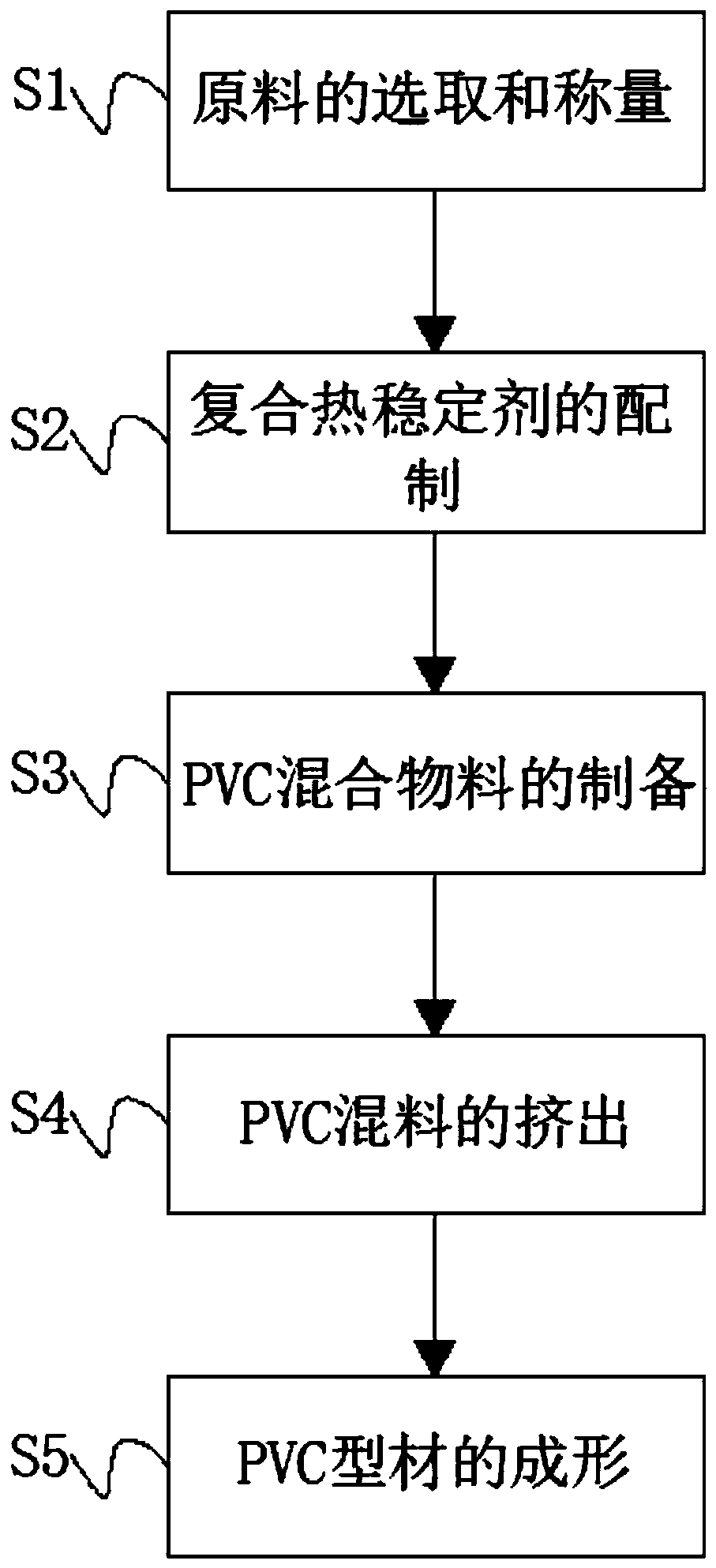

[0031] S1. Selection and weighing of raw materials: First, measure 55 parts of PVC resin, 7 parts of fatty acid heat stabilizer, 3 parts of light stabilizer, 3 parts of polyol ingredients, and 3 parts of phosphorous acid by weighing equipment ester, 7 parts of organotin heat stabilizer and 3 parts of antioxidant, and store the measured components through the storage tank for preparation. The fatty acid heat stabilizer is organic fatty acid, naphthenic acid, oleic acid, benzene A composition of formic acid and salicylic acid, a polyol ingredient of glycerin, trimethylolethane, pentaerythritol, xylitol and sorbitol, a light stabilizer of carbon black, zinc oxide and titanium dioxide, an antioxidant For the composition of tea polyphenols and butylated hydroxyanisole:

[0032]S2. Preparation of composite heat stabilizer: Add the fatty acid heat stabilizer, polyol ingredients and phosphite measured in step S1 into the mixing and stirring equipment in sequence, and stir for 35 minut...

Embodiment 2

[0037] S1. Selection and weighing of raw materials: First, measure 50 parts of PVC resin, 10 parts of fatty acid heat stabilizer, 5 parts of light stabilizer, 5 parts of polyol ingredients, and 5 parts of phosphorous acid by weighing equipment ester, 10 parts of organotin heat stabilizer and 5 parts of antioxidant, and store the measured components through storage tanks for preparation. The fatty acid heat stabilizer is a composition of organic fatty acid and salicylic acid. The alcohol ingredient is a composition of glycerin and sorbitol, the light stabilizer is a composition of carbon black and titanium dioxide, and the antioxidant is tea polyphenols:

[0038] S2. Preparation of composite heat stabilizer: Add the fatty acid heat stabilizer, polyol ingredients and phosphite measured in step S1 into the mixing and stirring equipment in sequence, and stir for 30 minutes at a speed of 400r / min and a temperature of 30°C. , capable of forming a heat stabilizer mixture, then adding...

Embodiment 3

[0043] S1. Selection and weighing of raw materials: First, measure 60 parts of PVC resin, 5 parts of fatty acid heat stabilizer, 1 part of light stabilizer, 1 part of polyol ingredients, and 1 part of phosphorous acid by weighing equipment ester, 5 parts of organotin heat stabilizer and 1 part of antioxidant, and store the measured components through storage tanks for preparation. The fatty acid heat stabilizer is organic fatty acid, and the polyol ingredient is glycerol, which is light stable The agent is carbon black, and the antioxidant is butyl hydroxyanisole:

[0044] S2. Preparation of composite heat stabilizer: Add the fatty acid heat stabilizer, polyol ingredients and phosphite measured in step S1 into the mixing and stirring equipment in sequence, and stir for 40 minutes at a speed of 600r / min and a temperature of 35°C. , capable of forming a heat stabilizer mixture, then adding the organotin heat stabilizer measured in step S1 to the heat stabilizer mixture, stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com