Flat panel liquid absorption core with complex structure and manufacturing method of flat panel liquid absorption core

A composite structure and liquid absorbing core technology, applied in the field of heat transfer, can solve the problems of poor control of pore structure, complex double pore structure, complex process, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

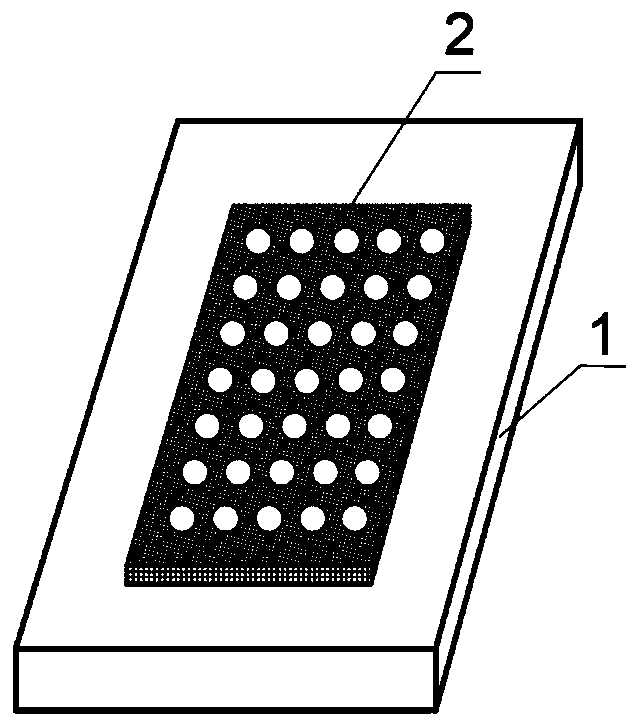

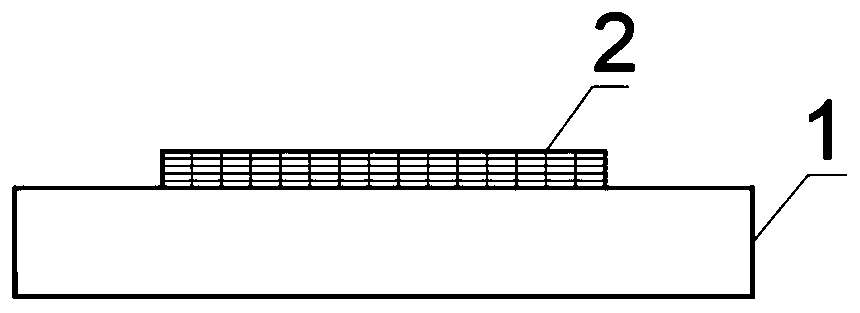

[0032] see figure 1 , an embodiment of the flat liquid-absorbent core with a composite structure provided by the example of the present invention, comprising: a thermally conductive substrate 1 , and a flat liquid-absorbent core 2 with a composite structure manufactured by 3D additive manufacturing.

[0033] (1) The pore structure of the flat liquid-absorbing core of the composite structure is drawn by 3D software, and imported into the 3D printing system for additive manufacturing after slicing.

[0034] (2) The flat liquid-absorbing core of the composite structure is directly clad on the heat-conducting substrate of the same material by 3D printing technology, and the composite pore structure manufactured effectively reduces the thermal resistance with the heat-conducting substrate.

[0035] (3) The flat liquid-absorbing core of the composite structure is manufactured by 3D printing technology, and the powder layer by layer is formed by laser line scanning and sintering. Eac...

Embodiment 2

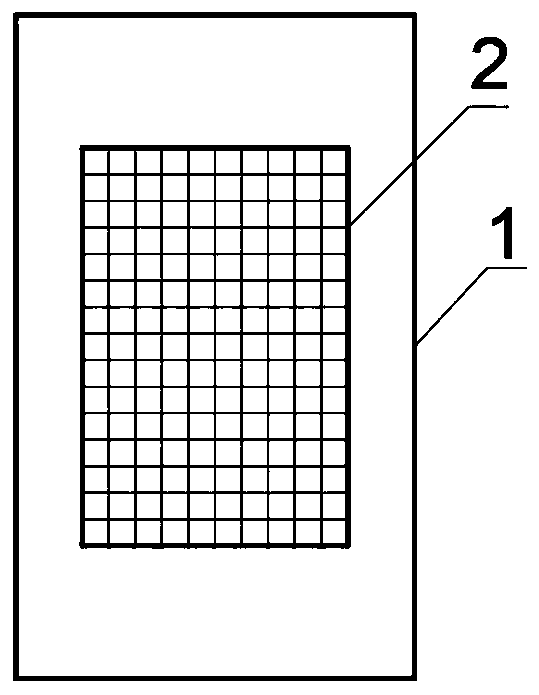

[0044] In this embodiment, the manufacturing process of the flat liquid-absorbing core with composite structure is the same as that in Embodiment 1. The structure of the absorbent core is as Figure 4 As shown, the metal powder material for 3D printing is selected from aluminum alloy, stainless steel, titanium alloy or nickel alloy according to specific heat dissipation applications. The printed structure in this embodiment is a rectangular groove structure nested in a small square base hole structure. The manufacturing method is the same as in Example 1, and the small base holes are connected to each other. Micro-scale or nano-scale or micro-nano-composite pores on the wall of the small base pore structure can improve the capillary liquid absorption capacity, and cooperate with the channel structure to help reduce heat transfer resistance and improve heat transfer effect.

[0045] Those skilled in the art can clearly see that for the convenience of describing the manufacturi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com