Reinforced and toughened syndiotactic polystyrene and preparation method thereof

A polystyrene, strengthening and toughening technology, which is applied in the field of polystyrene preparation, can solve the problems of syndiotactic polystyrene without toughening and strengthening, and achieve the effects of easy sequence distribution, improving toughness and strength, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The present invention also provides a method for preparing reinforced toughened syndiotactic polystyrene, comprising the following steps:

[0062] Under anhydrous and oxygen-free conditions, the organic solution of the catalyst composition is added to the mixed solution of styrene and styrene monomer modified by para-position long-chain alkane, and the copolymerization is carried out, and the enhanced toughening syndiotactic polymerization is prepared in situ. Styrene;

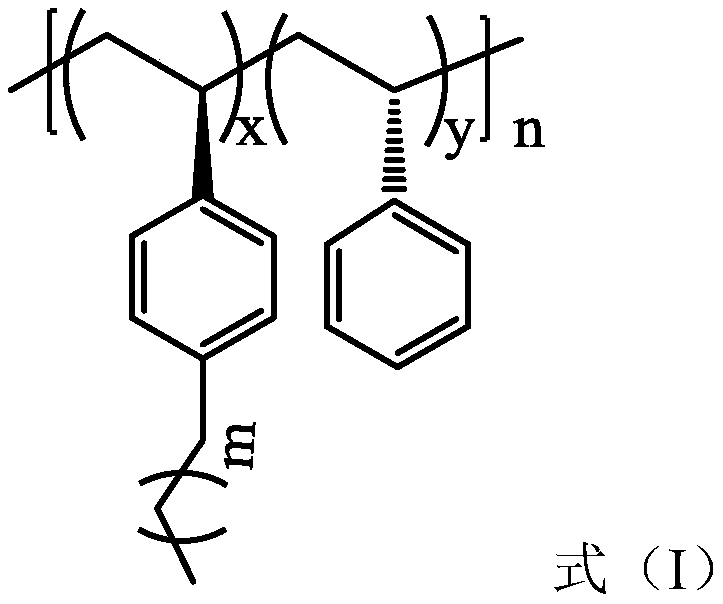

[0063] The reinforced and toughened syndiotactic polystyrene has a segment shown in formula (I):

[0064]

[0065] In formula (I), 0.5mol%

[0066] The styrene monomer modified by the para-position long-chain alkane has a structure shown in formula (II):

[0067]

[0068] In formula (II), 7≤m≤49;

[0069] The catalyst composition is composed of rare earth compound, organoboron salt and alkylaluminum.

[0070] The preparation method of the catalyst comp...

Embodiment 1

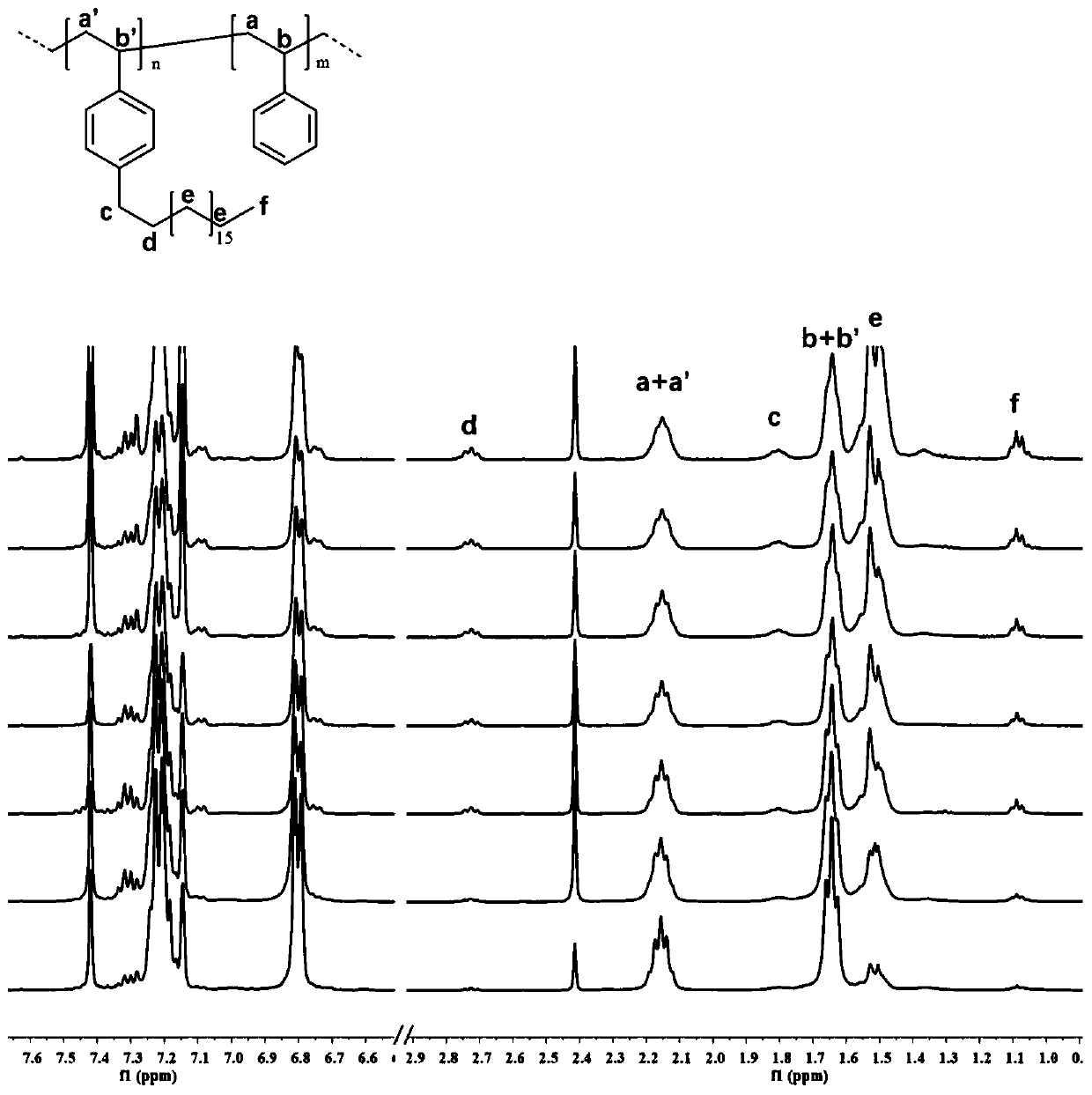

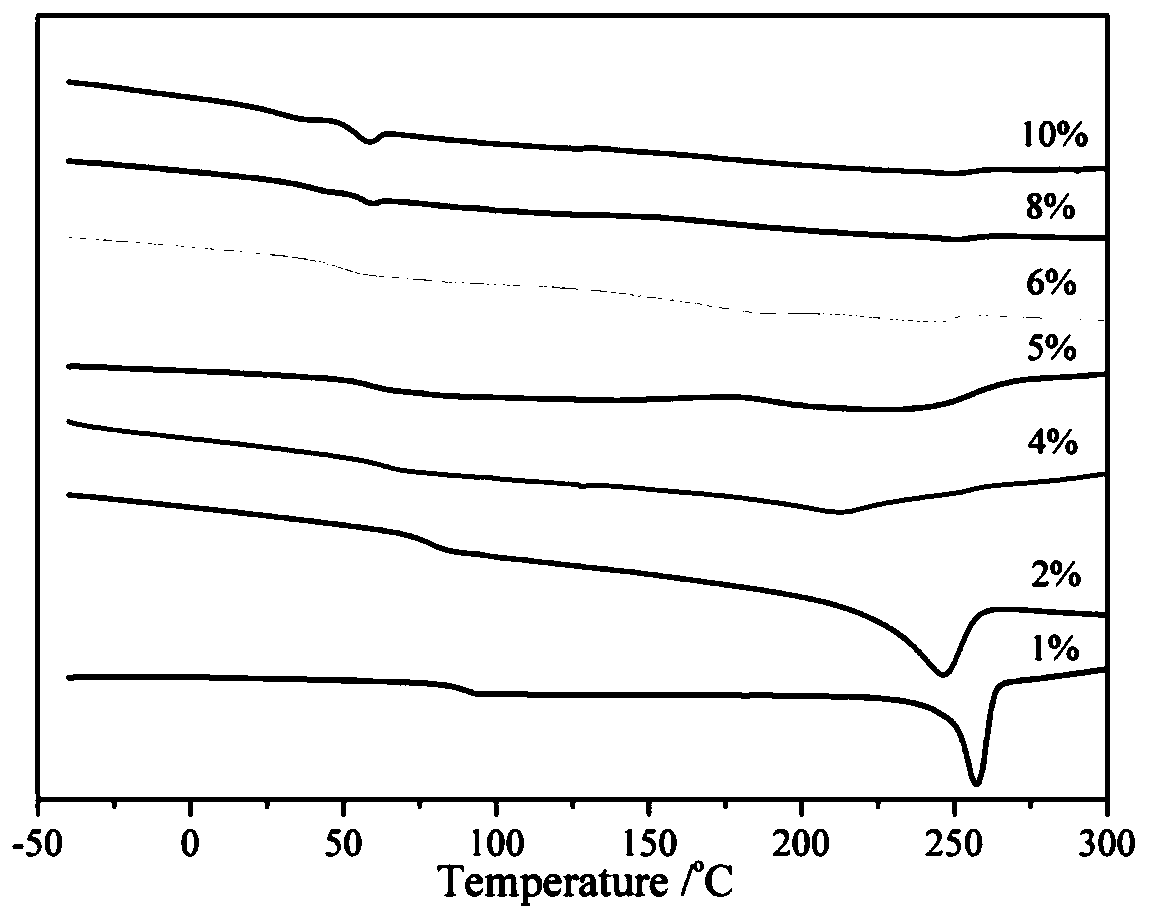

[0102] Under anhydrous and oxygen-free conditions, 10 μmol [Ph 3 C][B(C 6 f 5 ) 4 ] in 1 mL of toluene solution was poured into 2 mL of toluene solution of 10 μmol rare earth compound 2c, and then 200 μmol AiiBu was added 3 , configured as a toluene solution of the catalyst composition. The toluene solution of this catalyst composition is added in the 3 milliliters of toluene solutions that fill 2.062g styrene monomer (19.8mmol) and 0.0741g p-nonadecylstyrene monomer (0.2mmol), react at 25 ℃ for 1 Hours later, an ethanol solution containing an anti-aging agent was added to terminate the polymerization reaction, and the polymer obtained by sedimentation was dried in a vacuum oven at 50° C. for 48 hours to obtain the target product. The molar content of p-nonadecylstyrene structural units in the polymer is about 1.0%, and the number average molecular weight is 28.7×10 4 , the molecular weight distribution is 2.02, the glass transition temperature is 91°C, and the melting te...

Embodiment 2~12

[0103] Examples 2-12: The experimental procedures of this series of examples are the same as those of Example 1, and the polymerization reaction conditions, the change conditions of the catalytic system and the polymerization results are described in detail in the following table.

[0104]

[0105] The polymerization conditions are: the amount of rare earth compound is 10 μmol, [Ln]:[Ph 3 C][B(C 6 f 5 ) 4 ]:[Al i Bu 3 ] = 1:1:20 (mol / mol / mol), the concentration of the monomer in toluene solution is 2mol / L, [a] high temperature GPC: take polystyrene as the standard sample, 1,2,4- Trichlorobenzene as eluent, the measured value obtained. [b] Measured by DSC, after eliminating the thermal history, the heating rate is 10°C / min. The c polymerization condition is [Ln]:[Ph 3 C][B(C 6 f 5 ) 4 ]:[Al i Bu 3 ]=1:1:40 (molar ratio). [d] The aggregation condition is [Ln]:[Ph 3 C][B(C 6 f 5 ) 4 ]:[Al i Bu 3 ]=1:1:100 (molar ratio). Ln represents the central metal of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com