Preparation method of aluminosilicate composite rubber sealing material

A technology of aluminosilicate and sealing materials, which is applied in the field of preparation of aluminosilicate composite rubber sealing materials, can solve environmental pollution and other problems, and achieve the effects of uniform texture, small particle size, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

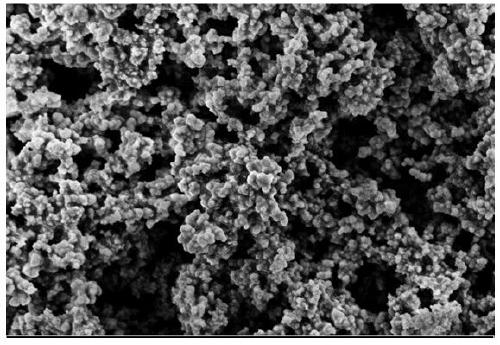

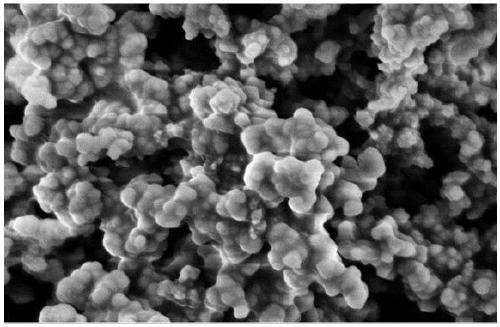

[0024] The first step: add a certain amount of aluminum salt to the bamboo pulp green liquor according to the ratio of silicon to aluminum molar ratio of 1:0.5 (dropping speed 1 ml / min), heat the reaction temperature in a water bath at 25 ℃, and use a stirrer to continue during the reaction Stirring, stirring speed 200 r / min, stirring time 10 min. After the reaction is over, filter out the precipitate, wash it repeatedly with clear water until it becomes neutral, and finally wash it with ethanol, and dry it at 50°C to obtain aluminosilicate powder, which can be seen figure 1 and figure 2 .

[0025] Step 2: Add the prepared aluminosilicate to water, add sodium polyacrylate dispersant with a mass ratio of 0.5% relative to the aluminosilicate, and stir ultrasonically for 3 minutes to make aluminosilicate with a concentration of 5%. suspension.

[0026] The third step: take 6% of the bleached coniferous wood fiber relative to the mass percentage of the total raw material, add ...

Embodiment 2

[0029] Step 1: Add a certain amount of aluminum salt (drop rate 1.5 ml / min) to the bamboo pulp green liquid according to the ratio of silicon to aluminum molar ratio of 1:1. Heat the reaction temperature in a water bath at 40 ° C. During the reaction, use a stirrer to continue Stirring, stirring speed 300 r / min, stirring time 15 min. After the reaction, the precipitate was filtered out, washed repeatedly with water until neutral, finally washed with ethanol, and dried at 50°C to obtain aluminosilicate powder.

[0030]Step 2: Add the prepared aluminosilicate to water, add a sodium polyacrylate dispersant with a mass ratio of 1% relative to the aluminosilicate, and stir ultrasonically for 5 minutes to prepare an aluminosilicate with a concentration of 7%. suspension.

[0031] The third step: take 8% bleached coniferous wood fiber relative to the mass percentage of the total raw material, add 8% aramid fiber relative to the mass percentage of the total raw material, add 6% miner...

Embodiment 3

[0034] The first step: add a certain amount of aluminum salt to the bamboo pulp green liquor according to the ratio of silicon to aluminum molar ratio of 1:1.5 (dropping speed 2 ml / min), heat the reaction temperature in a water bath at 60 ℃, and use a stirrer to continue during the reaction Stirring, the stirring speed is 400 r / min, and the stirring time is 20 min. After the reaction, the precipitate was filtered out, washed repeatedly with water until neutral, finally washed with ethanol, and dried at 50°C to obtain aluminosilicate powder.

[0035] Step 2: Add the prepared aluminosilicate to water, add sodium polyacrylate dispersant with a mass ratio of 1.5% relative to the aluminosilicate, and stir ultrasonically for 7 minutes to prepare aluminosilicate with a concentration of 9%. suspension.

[0036] The third step: take 10% of the bleached coniferous wood fiber relative to the mass percentage of the total raw material, add 10% of the aramid fiber relative to the mass perc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com