Indium-doped N-type organic thin-film transistor and preparation method thereof

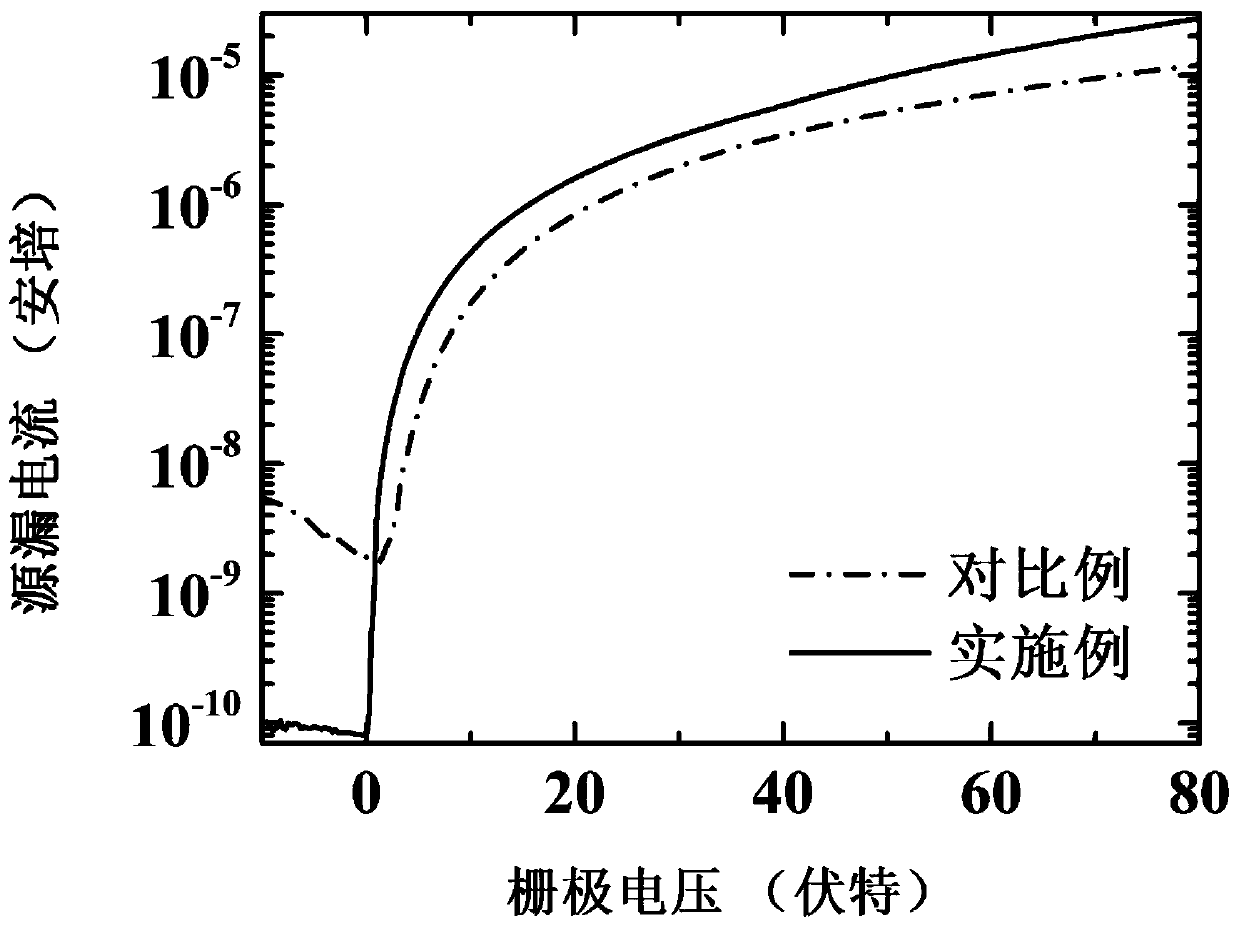

An organic thin film and transistor technology, which is applied in the field of indium-doped N-type organic thin-film transistor and its preparation, can solve the problems of limiting the development of flexible electronic devices and organic integrated circuits, high mobility, and shortage of N-type semiconductor materials, etc. Improved switching ratio and carrier mobility, low cost, and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] A1: Configuration of semiconductor solution

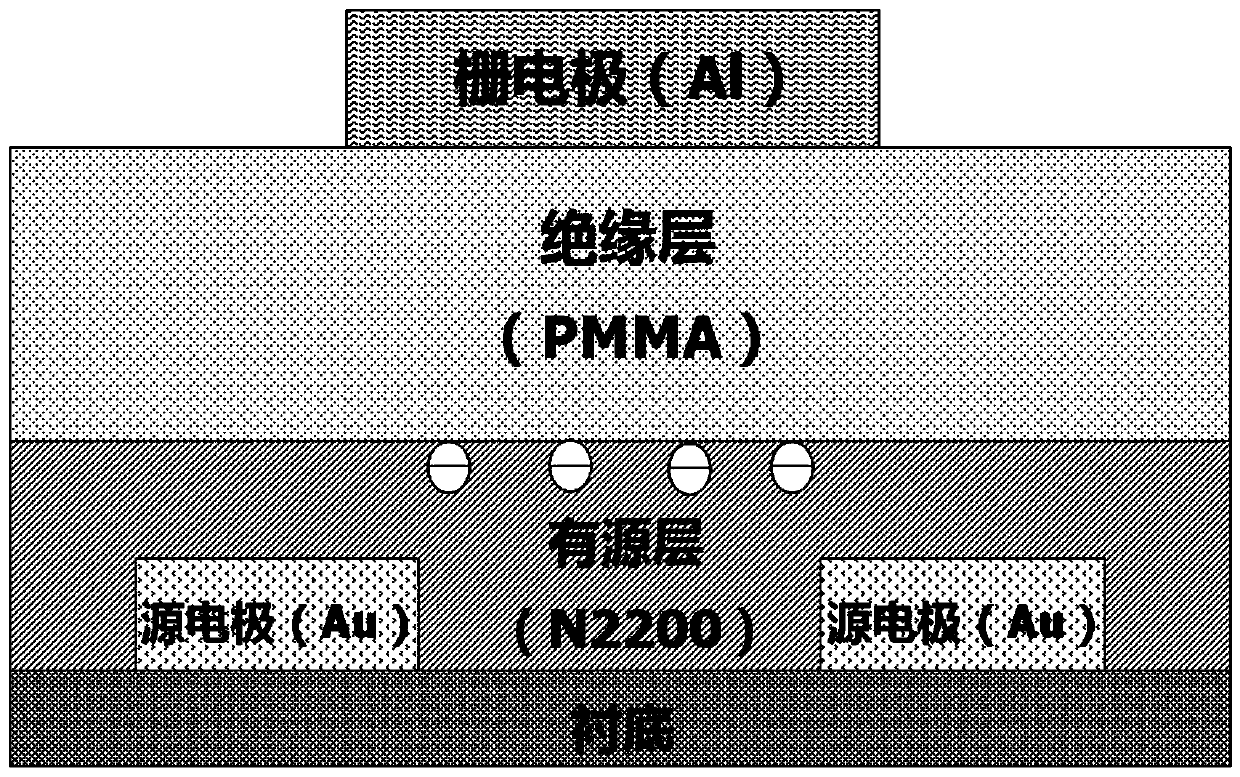

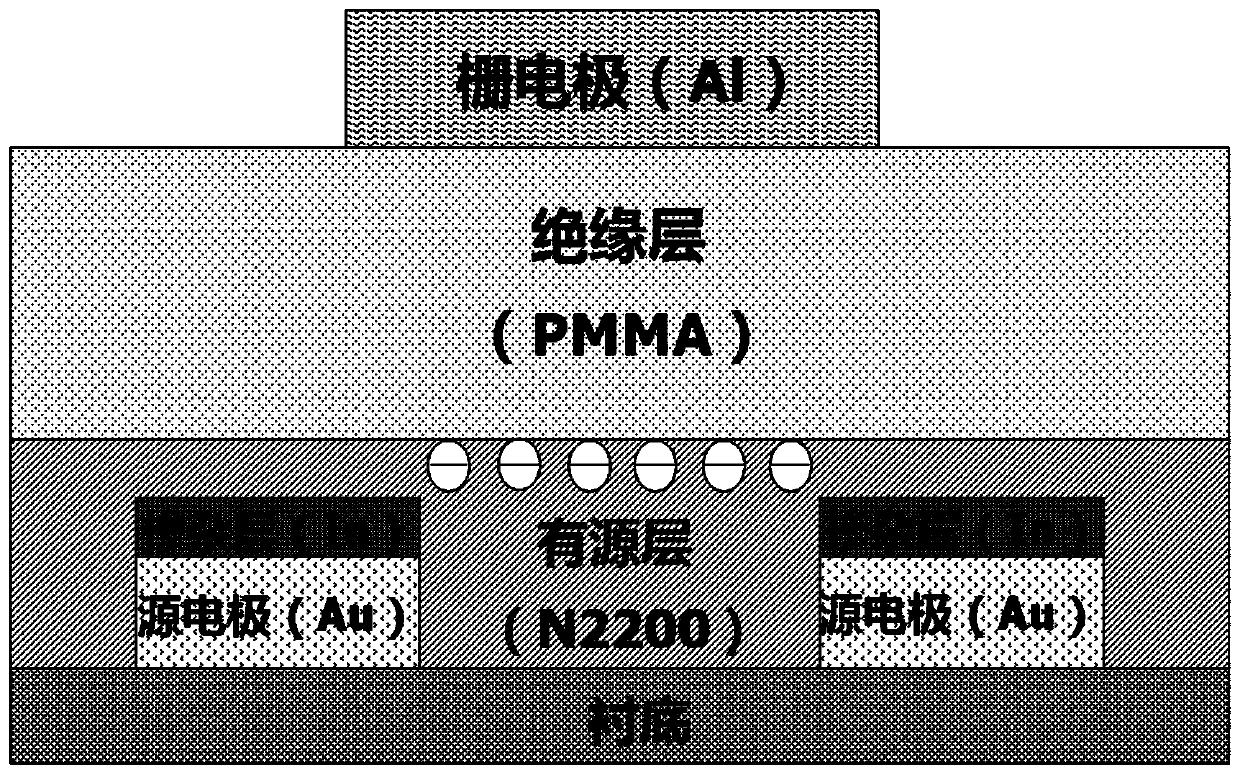

[0059] The N-type organic semiconductor material and the organic solvent are configured at a mass volume ratio of 8 mg / ml; wherein, the N-type organic semiconductor material is: [N,N'-bis(2-octyldodecyl)-1 , 4,5,8-naphthalene diimide-2,6-two bases-and-5,5'-(2,2'-bithiophene)] polymer (N2200); the organic solvent is chlorobenzene ;

[0060] A2: Configuration of insulating layer solution

[0061] The insulating layer material and the highly soluble organic solvent are configured with a mass volume ratio of 80mg / ml; wherein, the insulating layer material is polymethacrylate (PMMA); the highly soluble organic solvent is methyl acetate ester;

[0062] A3: Dissolution of the solution

[0063] Place the configured semiconductor solution and insulating layer solution on the heating plate at 60°C for 24 hours to dissolve;

[0064] Step 2: Preparation of Devices

[0065] B1: Cleaning of the substrate

[0066] Select an insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com