Method for preparing carbon-coated porous silicon material for lithium battery electrode

A porous silicon and carbon coating technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as poor conductivity and volume expansion, achieve good battery performance, alleviate poor conductivity, and be conducive to large-scale industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

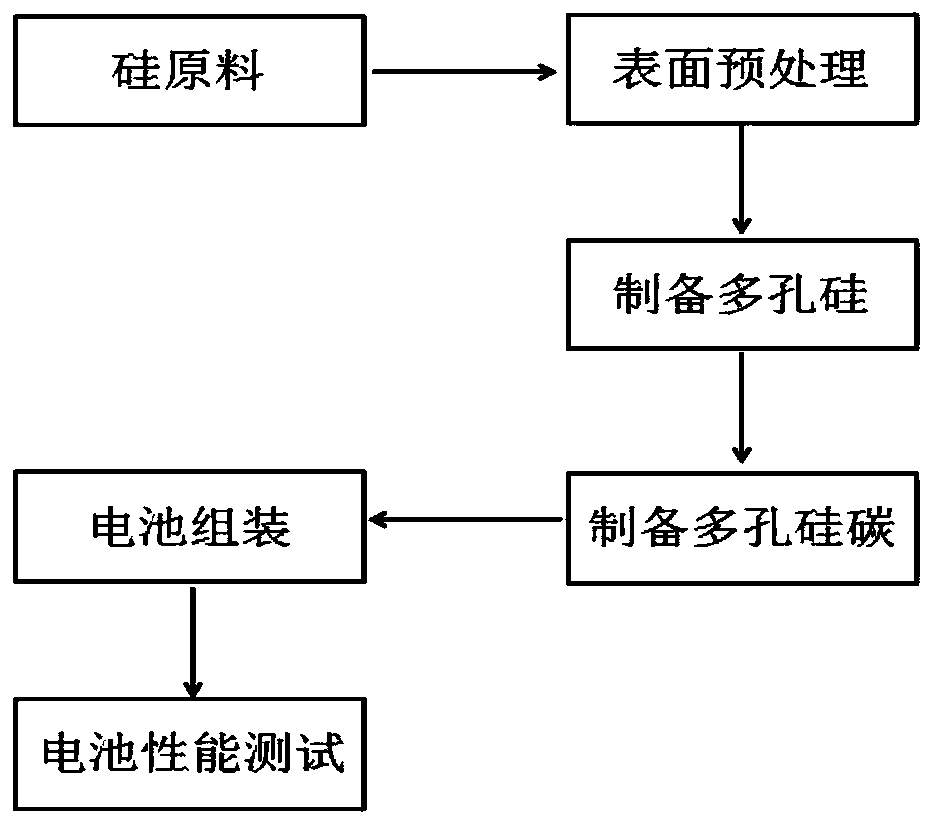

[0027] A method for preparing a carbon-coated porous silicon material for lithium battery electrodes, comprising the following steps:

[0028] 1) Using silicon powder with an average particle size of 15um as the raw material, pretreatment is performed first to remove oil stains and impurities on the surface of the silicon powder, and then the silicon powder is put into an ethanol solution and ultrasonicated for 30 minutes, and then put into deionized water for 30 minutes. , and finally dried in an oven for 5 hours for later use;

[0029] 2) Preparation of porous silicon, including: the first step, preparing a mixed solution containing 10mol / L hydrofluoric acid and 0.005mol / L silver nitrate, adding the silicon powder obtained in the step 1) to it, stirring and reacting at 20°C 10min, after the reaction is completed, wash with deionized water and suction filter, and dry to obtain silicon particles whose surface is modified by Ag particles; in the second step, put the silicon par...

Embodiment 2

[0033] A method for preparing a carbon-coated porous silicon material for lithium battery electrodes, comprising the following steps:

[0034] 1) Using silicon powder with an average particle size of 5um as the raw material, pretreatment is performed to remove oil stains and impurities on the surface of the silicon powder, and then the silicon powder is put into an acetone solution and ultrasonicated for 80 minutes, and then put into deionized water for 80 minutes. , and finally dried in an oven for 10 hours for later use;

[0035]2) Preparation of porous silicon, including: the first step, plating Ag on the silicon surface, first preparing a reducing agent, first mixing 15g / L glucose and 8g / L potassium sodium tartrate to boil, then adding 30ml / L ethanol and 12ml / L Polyethylene glycol is used to prepare the reducing agent, then mix 3g / L silver nitrate with 25ml / L ammonia water, 10ml / L ethylenediamine, and 10g / L potassium hydroxide to obtain the main salt, mix the main salt and...

Embodiment 3

[0039] A method for preparing a carbon-coated porous silicon material for lithium battery electrodes, comprising the following steps:

[0040] 1) Using silicon powder with an average particle size of 10um as the raw material, pretreatment is performed first to remove oil stains and impurities on the surface of the silicon powder, and then the silicon powder is put into an ethanol solution and ultrasonicated for 50 minutes, and then put into deionized water for 30 minutes. , and finally dried in an oven for 10 hours for later use;

[0041] 2) preparing porous silicon, including: the first step, evenly spread the silicon powder on the rotating sample stage, use high-purity Ag as the target material, turn on the instrument switch, and obtain the silicon material modified by Ag particles after sputtering; second The first step is to put the Ag particle-modified silicon particles into a mixed solution of 0.6 mol / L hydrogen peroxide and 0.8 mol / L hydrofluoric acid, etch at 25°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com