Novel sugar-free sugar cube and preparation method thereof

A new type of sugar cube technology, which is applied in the field of edible sugar, can solve the problems of easy moisture absorption, compactness and appearance damage, and affect the sales and use of sugar-free sugar cubes, and achieve the effect of reducing moisture absorption and prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

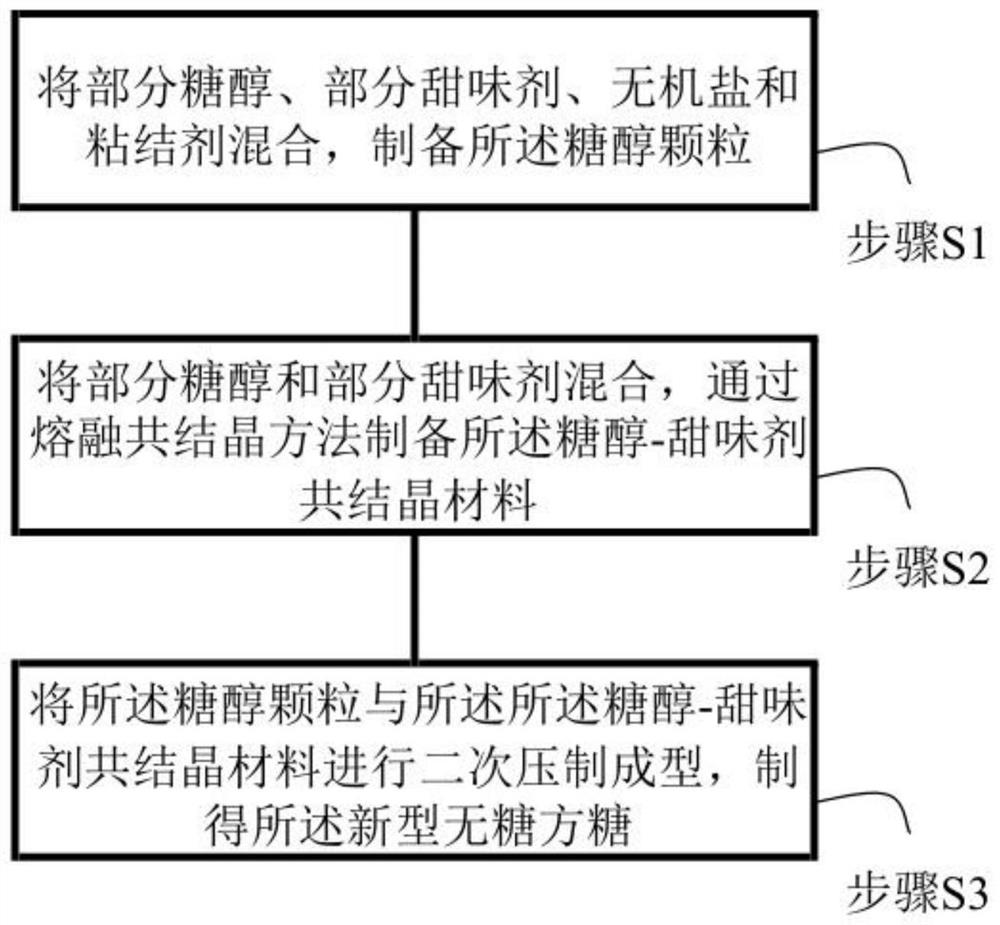

[0070] An exemplary embodiment of the present invention, such as figure 1 As shown in the figure, a preparation method of a novel sugar-free sugar cube comprises the following steps:

[0071] Step S1, preparing sugar alcohol granules

[0072] Mix part of sugar alcohol, part of sweetener, inorganic salt and binder to prepare sugar alcohol granules;

[0073] Step S2, preparation of sugar alcohol-sweetener co-crystal material

[0074] Mixing part of sugar alcohol and part of sweetener to prepare sugar alcohol-sweetener co-crystal material by melt co-crystallization method;

[0075] Wherein, the sugar alcohol-sweetener co-crystal material includes sugar alcohol-sweetener co-crystal particles and sugar alcohol-sweetener co-crystal powder;

[0076] Step S3, prepare a new type of sugar-free sugar cube

[0077] The sugar alcohol granules and the sugar alcohol-sweetener co-crystal material are subjected to secondary compression molding to prepare a novel sugar-free sugar cube.

[...

Embodiment 2

[0127] A specific embodiment of the present invention.

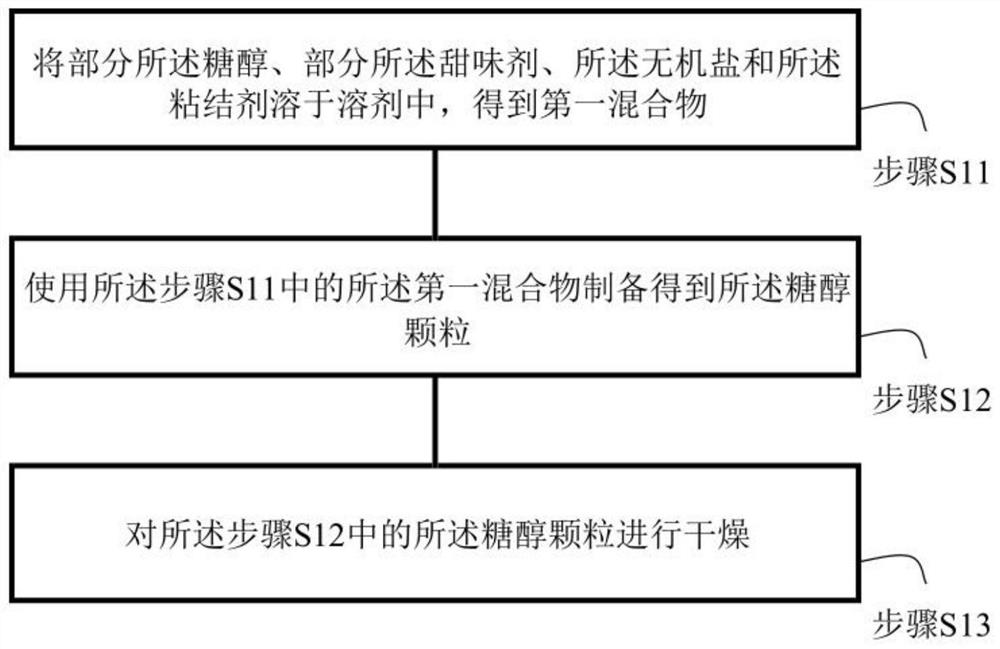

[0128] Step S1, preparing sugar alcohol granules

[0129] Step S11, dissolving 20.00kg isomalt that passed through a 100-mesh sieve, 2.50kg of sodium chloride, 0.375kg of mogroside and 3.27kg of pullulan that passed through a 100-mesh sieve in distilled water to obtain a first mixture;

[0130] Step S12, preparing the first mixture into sugar alcohol granules by wet granulation;

[0131] In step S13, the sugar alcohol particles in step S12 are dried. When the water content of the sugar alcohol particles is less than or equal to 3.0%, the drying is stopped, and the material is discharged after cooling down.

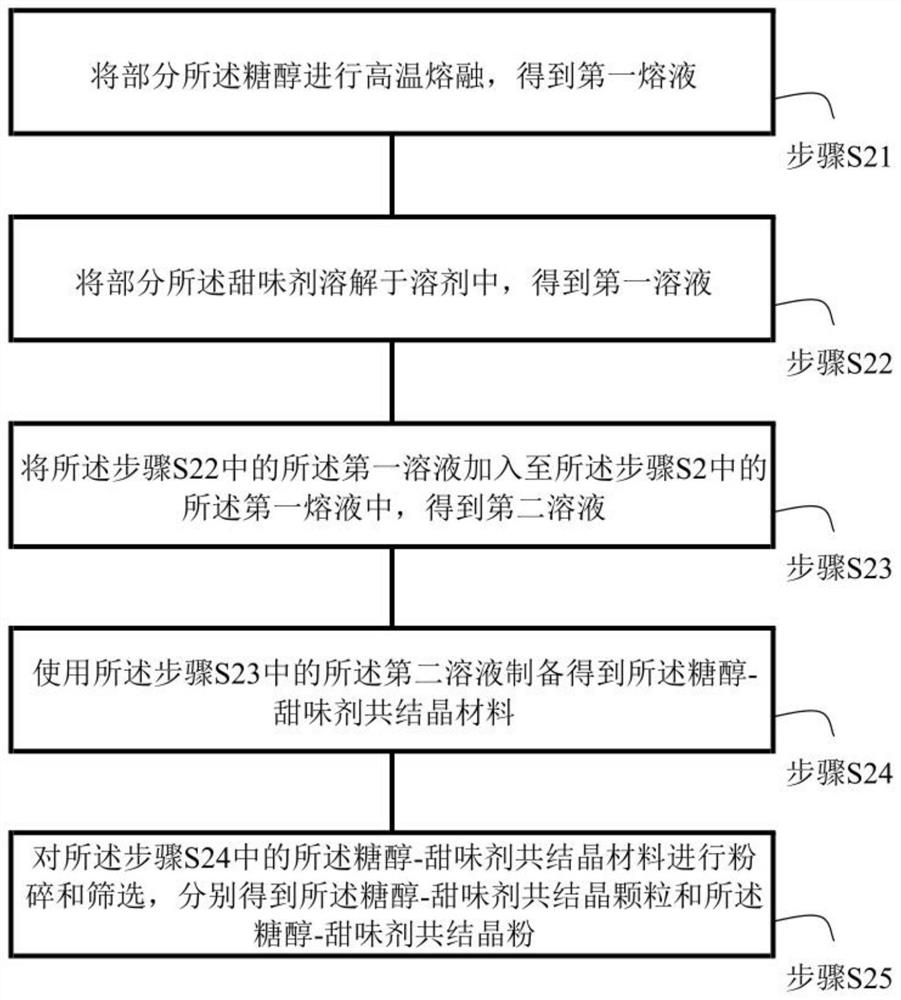

[0132] Step S2, preparation of sugar alcohol-sweetener co-crystal material

[0133] In step S21, 72.98kg of isomalt is melted at a high temperature at 150-155°C to obtain a clear first melt;

[0134] Step S22, at 90°C, dissolving 0.875kg of mogroside in distilled water to obtain a first solution, wherein the quali...

Embodiment 3

[0148] Step S1, preparing sugar alcohol granules

[0149] Step S11, dissolving 18.75kg of sorbitol that has passed through a 100-mesh sieve, 2.36kg of sodium chloride, 0.35kg of aspartame and 4.12kg of gum arabic that have passed through a 100-mesh sieve in distilled water to obtain a first mixture;

[0150] Step S12, preparing the first mixture into sugar alcohol granules by wet granulation;

[0151] In step S13, the sugar alcohol particles in step S12 are dried, and when the water content of the sugar alcohol particles is less than or equal to 2.5%, the drying is stopped, and the material is discharged after cooling down.

[0152] Step S2, preparation of sugar alcohol-sweetener co-crystal material

[0153] In step S21, 73.52kg of sorbitol is melted at a high temperature at 140-150°C to obtain a clear first melt;

[0154] Step S22, at 90° C., dissolving 0.90 kg of aspartame in distilled water to obtain a first solution, wherein the quality of the distilled water is 1.5 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com