Method for preparing three-dimensional metal micro-nano structure

A micro-nano structure and metal technology, applied in the manufacture of micro-structure devices, micro-structure technology, micro-structure devices, etc., can solve the problems of complex preparation process, achieve the effect of realizing broadband transmission, and the preparation process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Prepare the glass substrate 3, prepare the glass substrate 3 and clean it for use;

[0032] in particular:

[0033] The glass substrate 3 is specifically an ITO glass substrate. Prepare an ITO glass substrate 3 with a thickness of 1.0 mm and a length and width of 30.0 mm×30.0 mm, and put the prepared ITO glass into a washing solution for cleaning, and use deionized water to ultrasonically 5- After 10 minutes, use acetone to sonicate for 5-10 minutes, then use alcohol to sonicate for 5-10 minutes, and finally dry it with a nitrogen gun and put it in a nitrogen cabinet for later use.

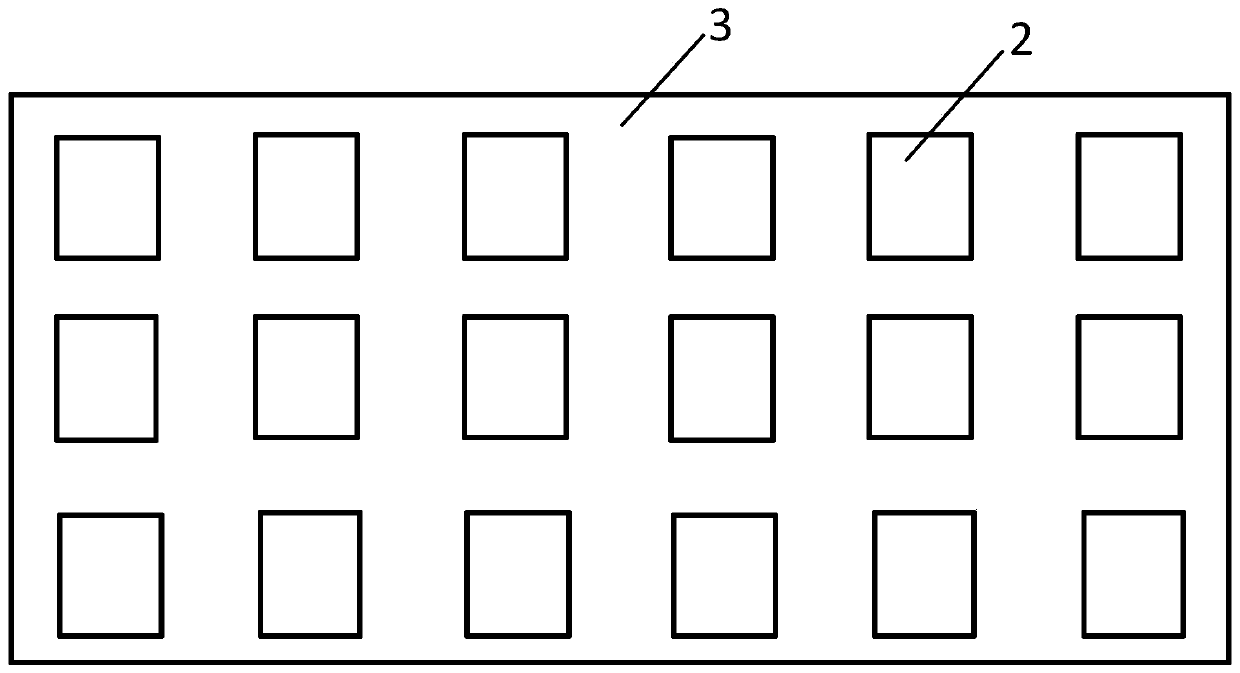

[0034] Step 2: Coating photoresist: throw two layers of positive photoresist on the surface of the glass substrate with a glue shaker; electron beam exposure structure pattern: design a square periodic array structure with a pattern generator; use an electron beam to design Fixed area exposure, the electron beam dose used is the first dose;

[0035] developing and fixing;

[0036...

Embodiment 2

[0051] For the three-dimensional metal micro-nano structure prepared in this example, only the thickness of the metal material layer 3 vertically evaporated by the electron beam evaporation coater is changed, and the preparation process is the same as that in Example 1.

[0052] in particular:

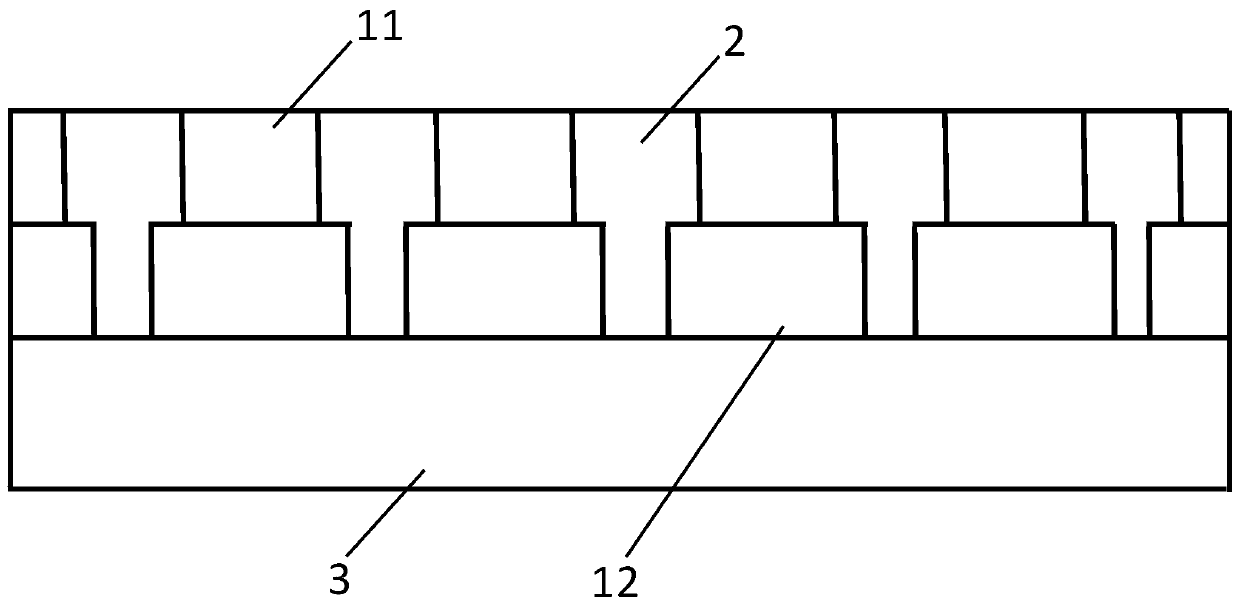

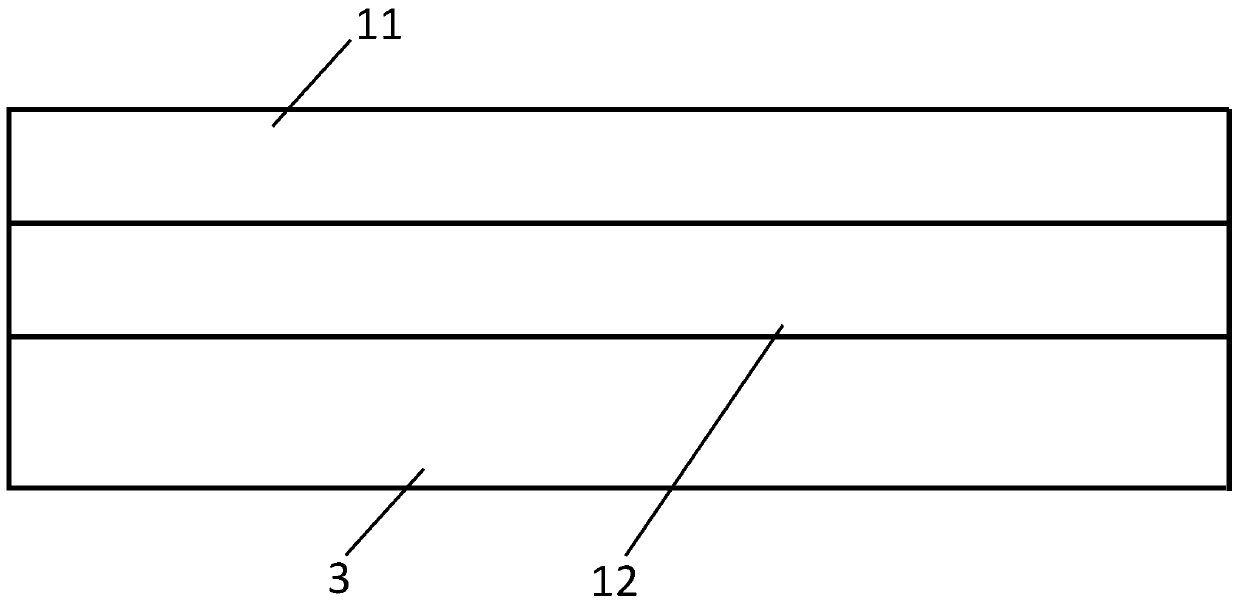

[0053] When coating the positive photoresist on the surface of the substrate with the glue spinner, the speed of the glue spinner is controlled, and then the thickness of the positive photoresist can be controlled, and the speed of the glue spinner is set at 1000rpm~6000rpm , and the time is set to 60s. The concrete step of described coating photoresist is, at first on the ITO glass substrate 3 spin-coating the positive resist with solid content of 4% with the glue-spinning machine, drying to form the first film 12, then spin-coating a layer with solid content of 2% positive resist is dried to form the second film 11 .

[0054] The three-dimensional metal micro-nano structure prepare...

Embodiment 3

[0056] For the three-dimensional metal micro-nano structure prepared in this example, only the angle of the metal material layer 3 evaporated by the electron beam evaporation coater is changed, and the preparation process is the same as that in Example 1.

[0057] in particular:

[0058] When adopting the electron beam vacuum evaporation coating instrument to vertically evaporate the metal material 3, by obliquely evaporating the metal material layer 3, the thickness of the metal material evaporated by the electron beam evaporation coating instrument is greater than the thickness of the first film 12, such as figure 1 shown. After evaporating the coating, the process of stripping the photoresist is carried out, soaking the ITO glass after evaporating the metal with acetone, dissolving the first film 12 and the second film 11, and the soaking time is at least 30 minutes. Afterwards, the substrate was blown dry with a nitrogen gun to obtain a three-dimensional chiral metal micro-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com