PVA (polyvinyl alcohol) powder modified rubber concrete and preparation method thereof

A technology for modifying rubber and concrete, which is applied in the field of concrete, and can solve problems such as strength reduction, and achieve the effects of reducing strength loss, improving performance, and increasing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of PVA powder modified rubber concrete of the present invention is:

[0033] In order to fully contact the PVA powder with the rubber particles, first, according to the amount of PVA powder and water, dissolve the PVA powder in water, make a PVA solution, and then mix the concrete. In order to ensure that the PVA powder is soluble in water and not decomposed, first put the PVA powder in a container and heat it at 75°C for 5 hours to dissolve it in water. After dissolving, let it stand for 0.5 hours to make a PVA solution and seal it for storage.

[0034] When preparing PVA powder-modified rubber concrete, according to the amount of rubber particles, put the rubber particles into the PVA solution, and put the PVA solution containing rubber particles into the ultrasonic equipment and use ultrasonic waves to disperse for 15 to 30 minutes to make the rubber particles Fully mix with the PVA solution; then, pour the cement, fine aggregate, coarse aggregat...

Embodiment 1

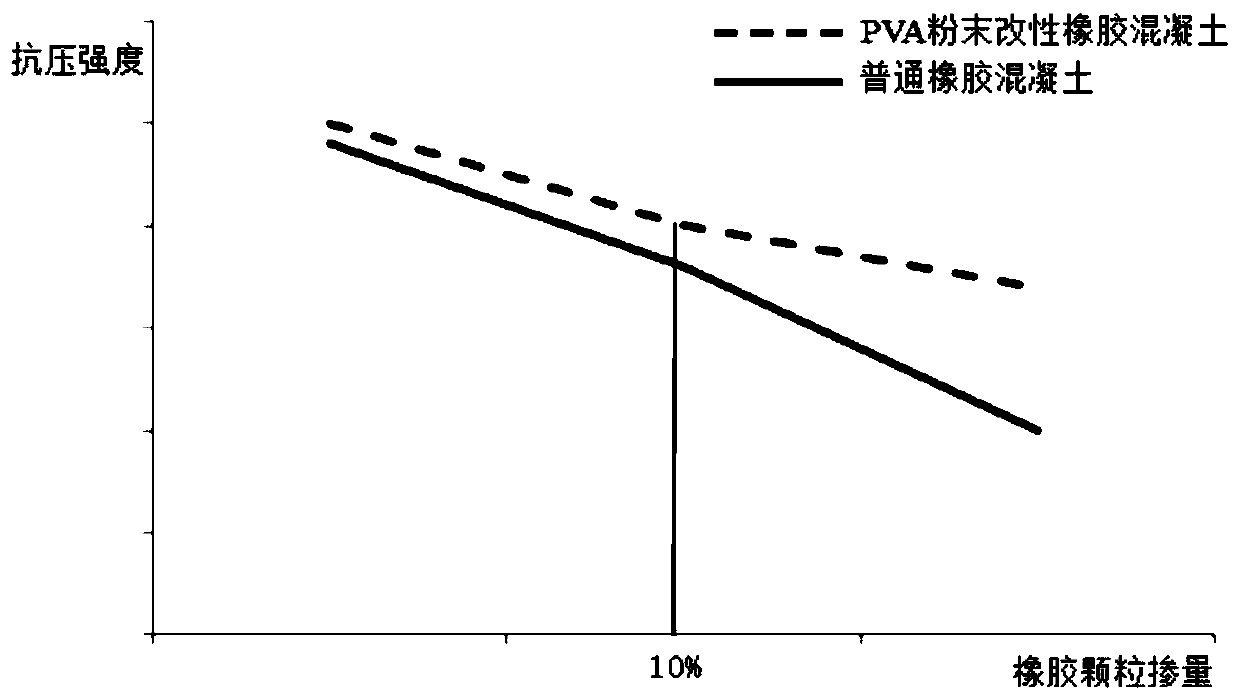

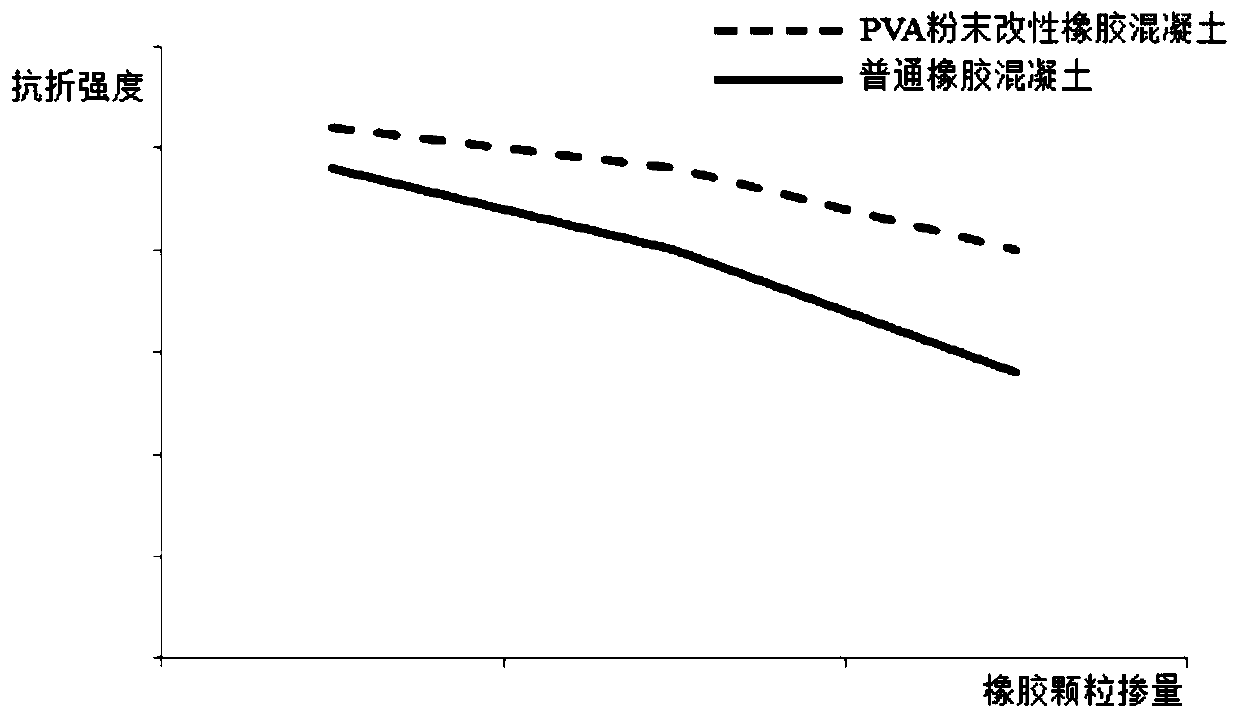

[0037] The amount of cement is 400kg / m 3 Concrete, the amount of fine aggregate is 800kg / m 3 Concrete, the amount of coarse aggregate is 1000kg / m 3 Concrete, the amount of rubber particles is 80kg / m 3 For concrete, the dosage of silica fume is 0kg / m 3 Concrete, the amount of expansion agent is 0kg / m 3 For concrete, the dosage of PVA powder is 0.6kg / m 3 Concrete, the amount of water is 120kg / m 3 For concrete, the dosage of water reducer is 2kg / m 3 Concrete, made by mixing cement, fine aggregate, coarse aggregate, rubber particles, silica fume, expansion agent, PVA powder, water and water reducer, with an apparent density of 2400kg / m 3 of concrete. The mix ratio has a lower amount of PVA powder, and the cost is the cheapest. Compared with ordinary rubber concrete, its compressive strength is increased by 15%, and its flexural strength is increased by 10%.

Embodiment 2

[0039] The amount of cement is 450kg / m 3 Concrete, the amount of fine aggregate is 700kg / m 3 Concrete, the amount of coarse aggregate is 900kg / m 3 Concrete, the amount of rubber particles is 140kg / m 3 For concrete, the dosage of silica fume is 5kg / m 3 Concrete, the amount of expansion agent is 10kg / m 3 For concrete, the dosage of PVA powder is 0.90kg / m 3 Concrete, the amount of water is 135kg / m 3 For concrete, the dosage of water reducer is 4.5kg / m 3 Concrete, made by mixing cement, fine aggregate, coarse aggregate, rubber particles, silica fume, expansion agent, PVA powder, water and water reducer, with an apparent density of 2350kg / m 3 of concrete. The mix ratio has a moderate amount of PVA powder, and the cost is low. Compared with ordinary rubber concrete, its compressive strength is increased by 20%, and its flexural strength is increased by 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com