Acid-resistant photo-controlled fluorescent molecular switch in aqueous solution, and synthesis method thereof

A technology of fluorescent molecules and synthesis methods, applied in the field of acid-resistant light-controlled fluorescent molecular switches and their synthesis, can solve the problems of inability to accurately detect metal cations, interference of experimental results, and limited applications, and achieve the effect of reducing background fluorescence interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] When R 1 = R 2 When =H, its molecular (P1) synthesis route and product structure are as follows:

[0028]

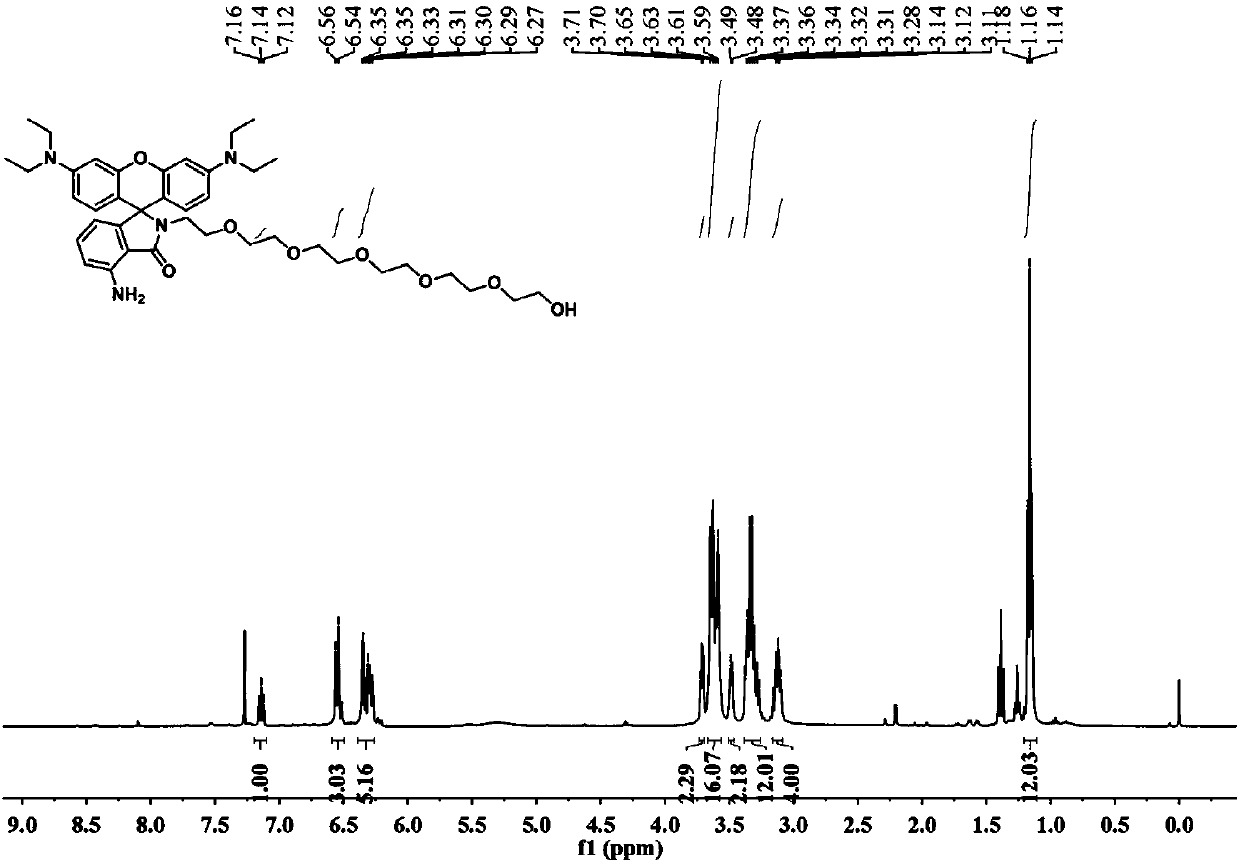

[0029] Synthesis steps and characterization: Dissolve 3-nitrorhodamine (2mmol, 0.974g) and aminohexapolyethylene glycol (2mmol, 0.562g) in absolute ethanol (5mL), heat up to 78°C and reflux, stir for 4 hours The solvent was distilled off under reduced pressure, and the product was separated and purified by column chromatography (silica gel, dichloromethane / methanol, 10:1 v / v) to obtain a pale yellow viscous liquid (1.42 g, 95%). Then this liquid product was all dissolved in methanol (5mL), stirred under hydrogen atmosphere and palladium carbon (10%wt) catalysis for 1 hour, suction filtered and got the filtrate, obtained the final white viscous liquid product P1 ( 1.35 g, 99%).

[0030] The product was subjected to NMR ( figure 1 ) and mass spectrometric characterization: 1 H NMR (400MHz, CDCl 3 )δ7.14(t,J=7.7Hz,1H),6.58–6.50(m,3H),6.38–6.26(m,5H),3.74–3....

Embodiment 2

[0034] When R 1 = H, R 2 =CH 3 When, its molecular (P2) synthesis route and product structure are as follows:

[0035]

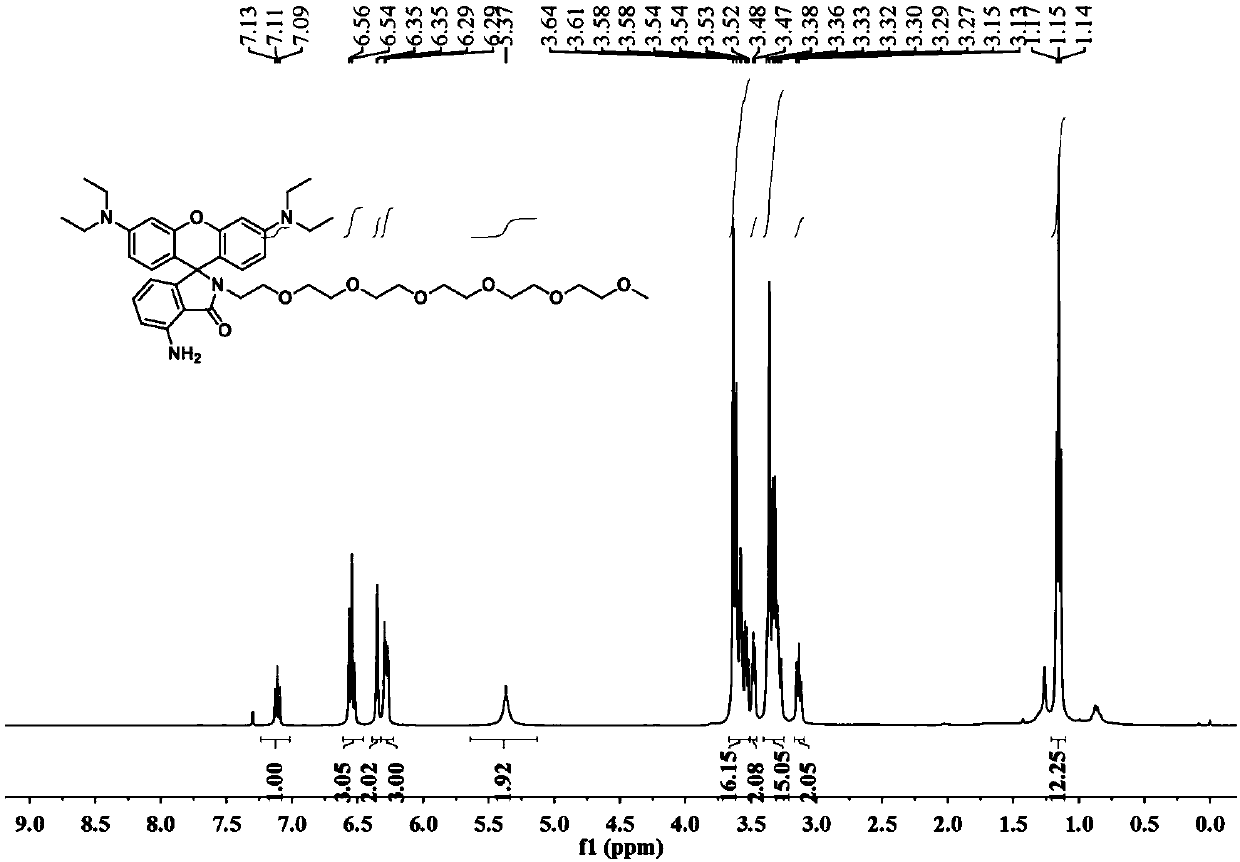

[0036] Synthesis steps and characterization: 3-Nitrorhodamine (0.24g, 0.5mmol) and aminohexapolyethylene glycol methyl ether (0.14g, 0.5mmol) were dissolved in absolute ethanol (8mL), heated to 78°C and refluxed, After stirring for 4 hours, the solvent was evaporated under reduced pressure, and the residue was separated by column chromatography (silica gel, ethyl acetate / methanol, 30:1 v / v) to obtain a viscous liquid (0.34 g, 90%). All of it was dissolved in methanol (5 mL) and 20 mg of 10% palladium on carbon was added for catalytic reduction under hydrogen atmosphere. The reaction mixture was filtered with suction, and the filtrate was evaporated to remove the solvent under reduced pressure. The product was separated by column chromatography (silica gel, ethyl acetate / methanol, 20:1 v / v) to obtain viscous liquid P2 (0.32 g, 96%).

[0037] The produc...

Embodiment 3

[0041] When R 1 =COCH 3 , R 2 =CH 3 When, its molecular (P3) synthesis route and product structure are as follows:

[0042]

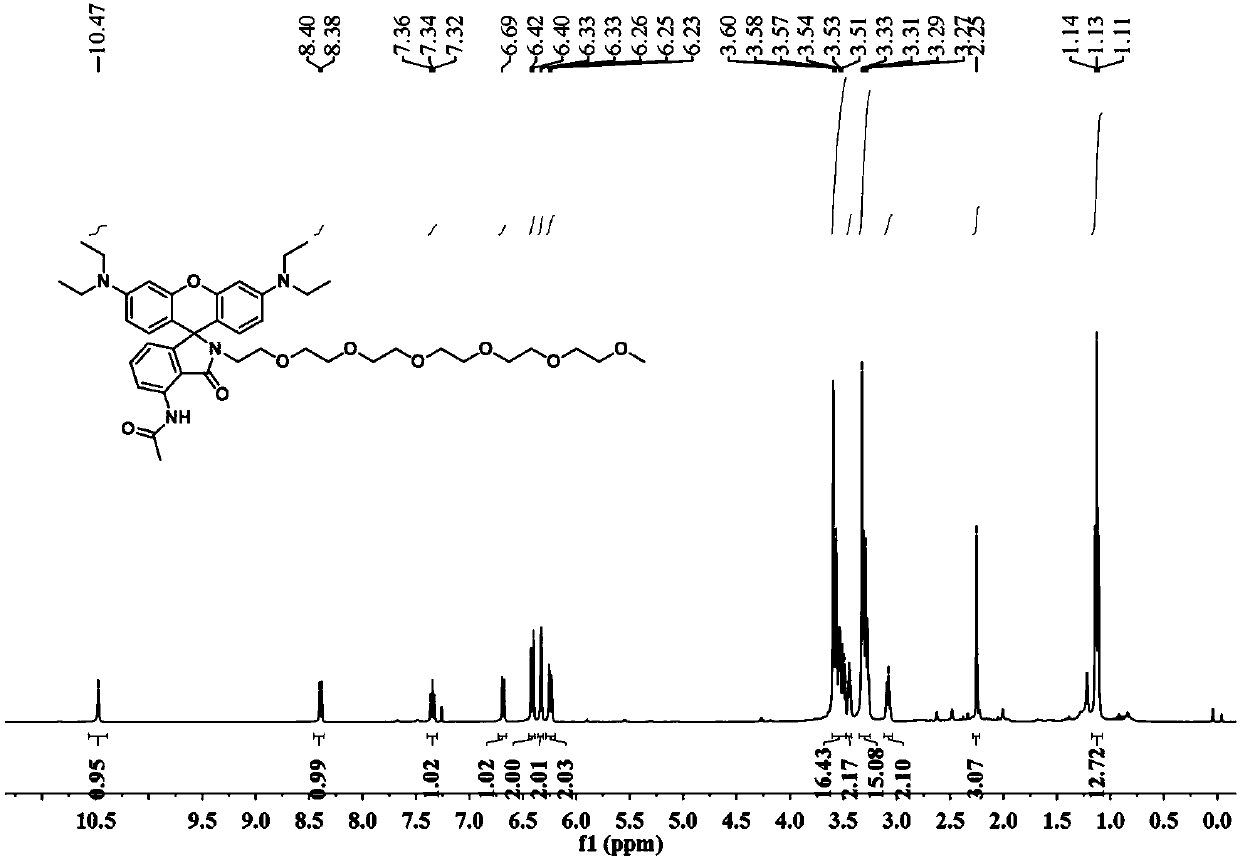

[0043] Synthesis steps and characterization: P2 (0.22g, 0.3mmol) and acetyl chloride (35mg, 0.45mmol) were mixed in dichloromethane (5mL), after stirring for 2 hours, the solvent was evaporated under reduced pressure and passed through column chromatography (silica gel, acetic acid Ethyl ester / methanol, 20:1 v / v) was isolated to give P3 (0.22 g, 95%) as a viscous liquid.

[0044] The product was subjected to NMR ( image 3 ) and mass spectrometric characterization: 1 H NMR (400MHz, CDCl 3 )δ10.47(s,1H),8.39(d,J=8.2Hz,1H),7.34(t,J=7.9Hz,1H),6.68(d,J=7.6Hz,1H),6.41(d, J=8.8Hz, 2H), 6.33(d, J=2.4Hz, 2H), 6.24(dd, J=8.9, 2.4Hz, 2H), 3.60–3.48(m, 16H), 3.47–3.42(m, 2H ), 3.35–3.25(m, 15H), 3.08(t, J=7.1Hz, 2H), 2.25(s, 3H), 1.13(t, J=7.0Hz, 13H). 13 CNMR (101MHz, CDCl 3 )δ169.06,168.82,153.52,152.97,148.66,136.57,133.85,128.43,117.79,117.38,115....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com