Chemical bath deposition method and CIGS photovoltaic module preparation method

A deposition method and chemical water bath technology, applied in photovoltaic power generation, chemical recycling, liquid chemical plating, etc., can solve the problems of high price of swing CBD, low deposition rate of CdS, negative effects of coating process, etc., to avoid chemical cleaning process, solve the effect of uniform heating of substrates, improve film formation efficiency and film formation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

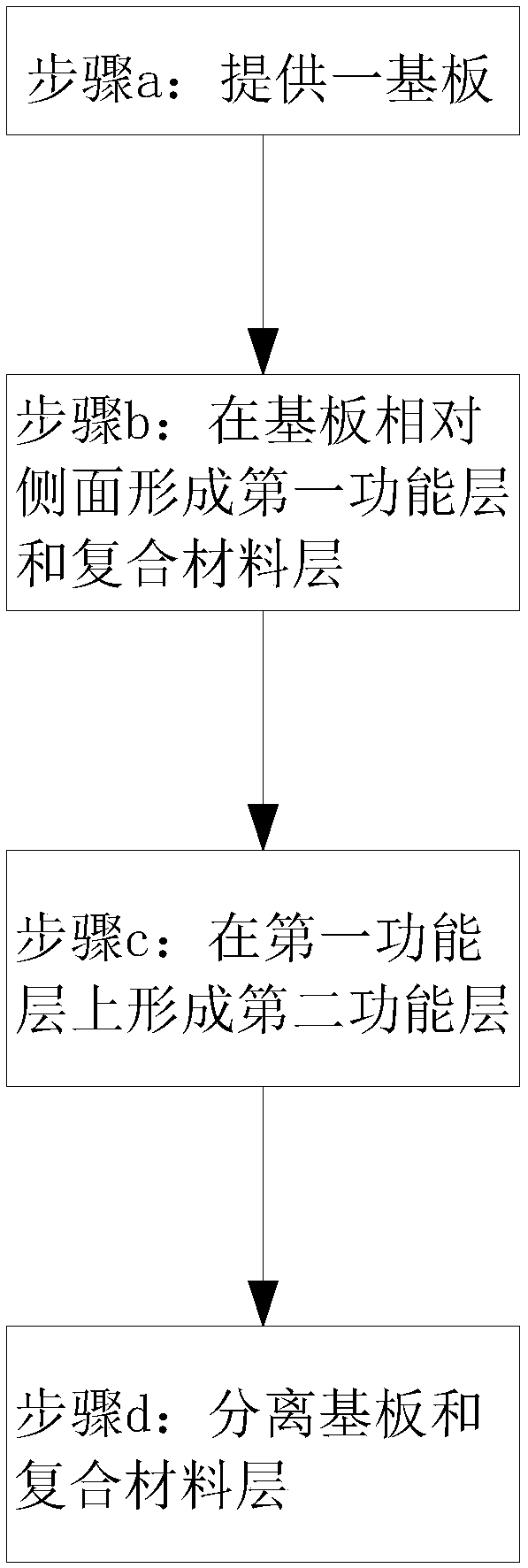

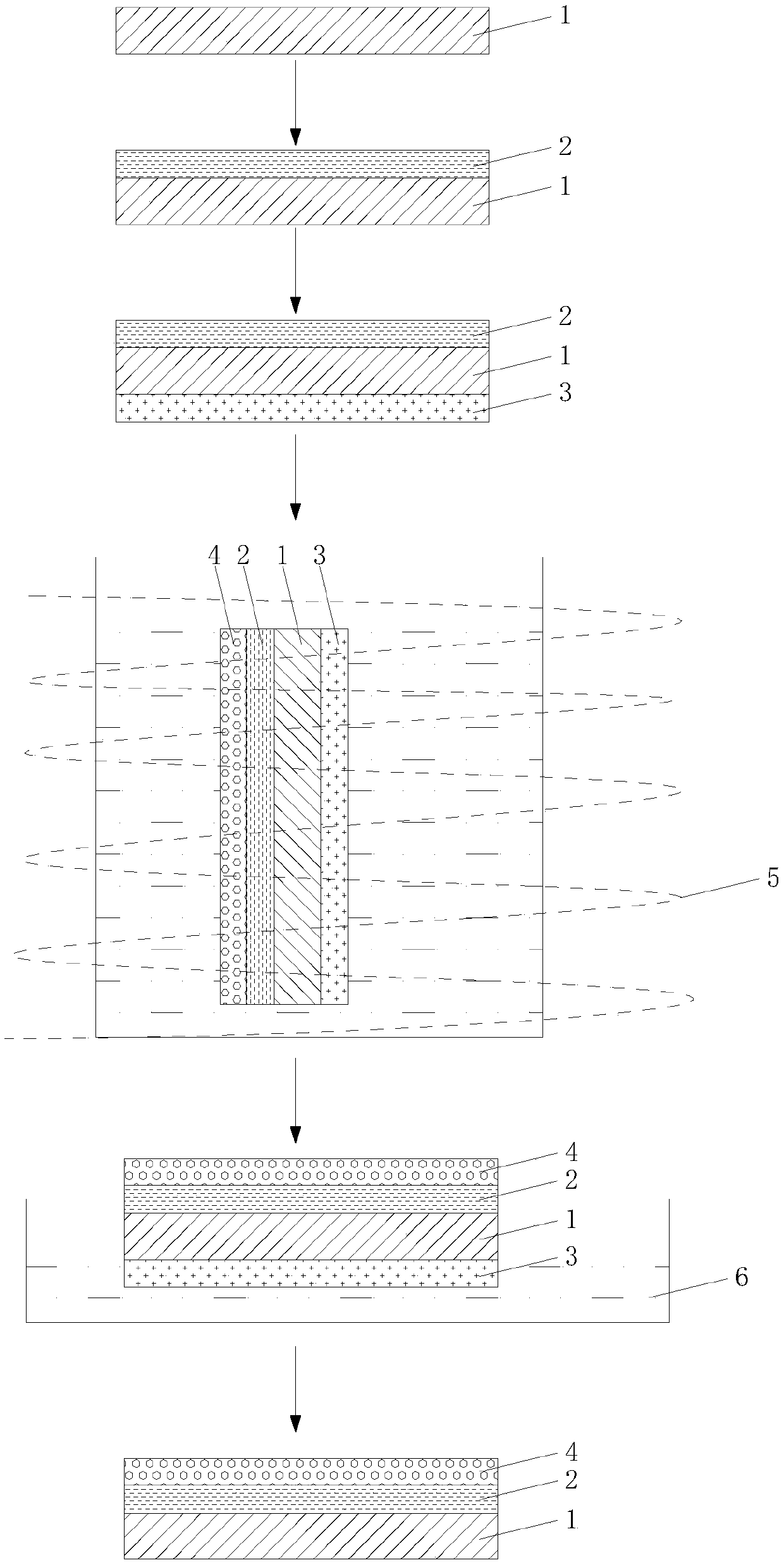

[0040] Such as figure 2 Shown, the present invention also provides a kind of preparation method of CIGS photovoltaic module, described method comprises the following steps:

[0041] S1. Provide a substrate 1;

[0042] S2, respectively forming a CIGS layer 2 and a composite material layer 3 on opposite sides of the substrate 1, the composite material layer 3 comprising a polymer hydrogel and magnetic nanoparticles mixed in the polymer hydrogel;

[0043] S3, placing the substrate 1 formed with the CIGS layer 2 and the composite material layer 3 in a deposition solution, and depositing a CdS layer 4 on the CIGS layer 2;

[0044] S4, separating the composite material layer 3 from the substrate 1 .

[0045] In step S1, the material of the substrate 1 is not limited, and any commonly used photovoltaic module substrate may be used, preferably a glass substrate.

[0046] In step S3, during the deposition process, an alternating magnetic field is used to inductively heat the substr...

Embodiment 1

[0051] refer to figure 1 and figure 2 , select a glass substrate 1 and coat a CIGS layer 2 on one side of the glass substrate 1 .

[0052] Then, the other side of the glass substrate 1 is coated with a composite material layer 3 by screen printing, and the composite material layer 3 includes a copolymerized cross-linked product of polyacrylic acid resin and Fe mixed in the copolymerized cross-linked product of polyacrylic acid resin. 3 o 4 Particles, the mass percentages of both are 90% and 10% respectively.

[0053] Then place the glass substrate 1 formed with the CIGS layer 2 and the composite material layer 3 vertically, and soak in a reaction tank filled with a premixed solution of cadmium sulfate, ammonia water, and pure water. Turn on alternating current 5 afterwards, and the frequency that it produces is the alternating magnetic field of 500kHz to make the Fe in composite material layer 3 3 o 4 The particles are heated rapidly so that the glass substrate 1 is heat...

Embodiment 2

[0057] refer to figure 1 and figure 2 , select a glass substrate 1 and coat a CIGS layer 2 on one side of the glass substrate 1 .

[0058] Then, the other side of the glass substrate 1 is coated with a composite material layer 3 by screen printing, and the composite material layer 3 includes polyvinyl alcohol and Fe mixed in polyvinyl alcohol. 3 o 4 Particles, the mass percentages of the two are 80% and 20% respectively.

[0059] Then place the glass substrate 1 formed with the CIGS layer 2 and the composite material layer 3 vertically, and soak in a reaction tank filled with a premixed solution of cadmium sulfate, ammonia water, and pure water. Turn on the alternating current 5 afterwards, and the frequency that it produces is the alternating magnetic field of 550kHz to make the Fe in the composite material layer 3 3 o 4 The particles are heated rapidly so that the glass substrate 1 is heated uniformly to 60°C. At this point the thiourea solution was added and CdS depo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com