Long-acting corrugated plate tunnel anti-rockburst device corrosion-resistant composite film and implementation method

A corrugated plate and composite membrane technology, which is applied to devices for coating liquid on surfaces, pretreatment surfaces, coatings, etc., to achieve the effects of not easy corrosion, improved conditions and difficulty, and reduced corrosion current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] A method for implementing a corrosion-resistant composite membrane for a long-term corrugated plate tunnel rockburst prevention device, comprising the following steps:

[0043] 1) Select SD360 nanofiber tunnel special primer, SD320 nanometer tunnel special potential adjustment paint, curing agent and organic solvent;

[0044] 2) Substrate surface pretreatment before film formation:

[0045] A. The corrugated steel surface substrate is subjected to surface blasting treatment;

[0046] B. Jet abrasive derusting reaches Sa3 level, and special parts are polished and derusted by power tools to St3 level;

[0047] C. The surface is required to be clean and dry during construction, and all visible grease, oil, dust, lubricants and other pollutants must be removed;

[0048] D. The construction surface must be cleaned repeatedly before each paint application, keep ventilation, and keep the inner wall dry;

[0049] 3) The surface cleanliness meets the above surface requirement...

Embodiment

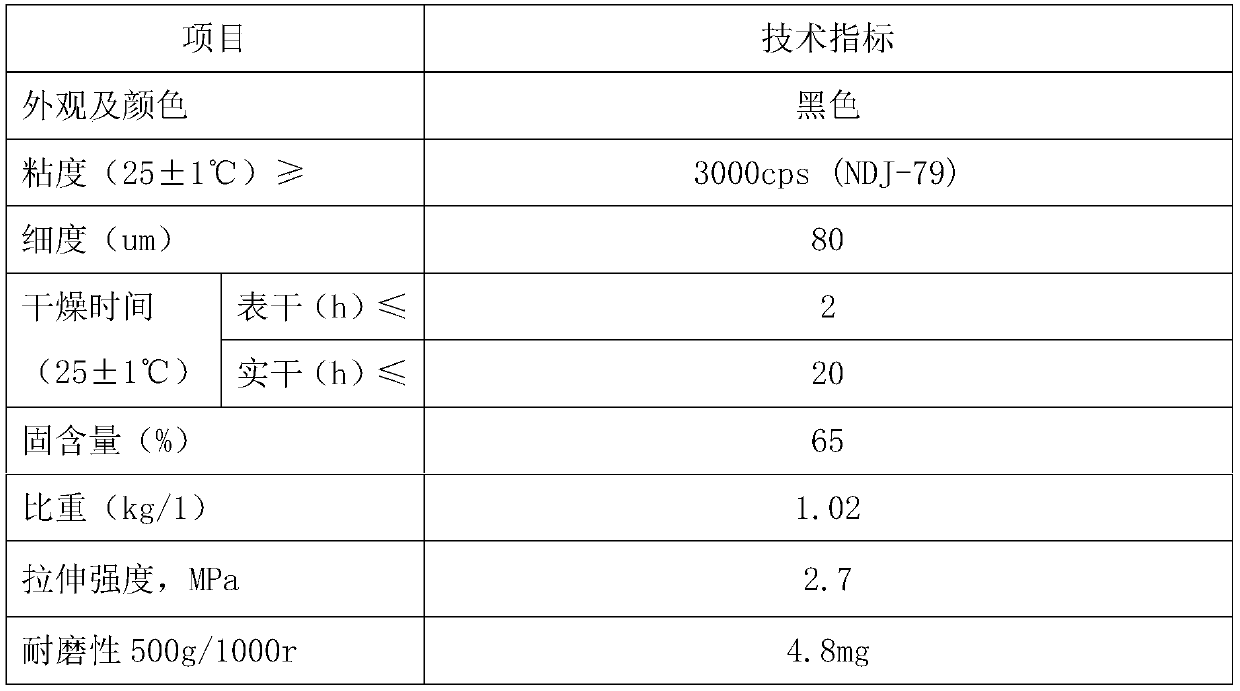

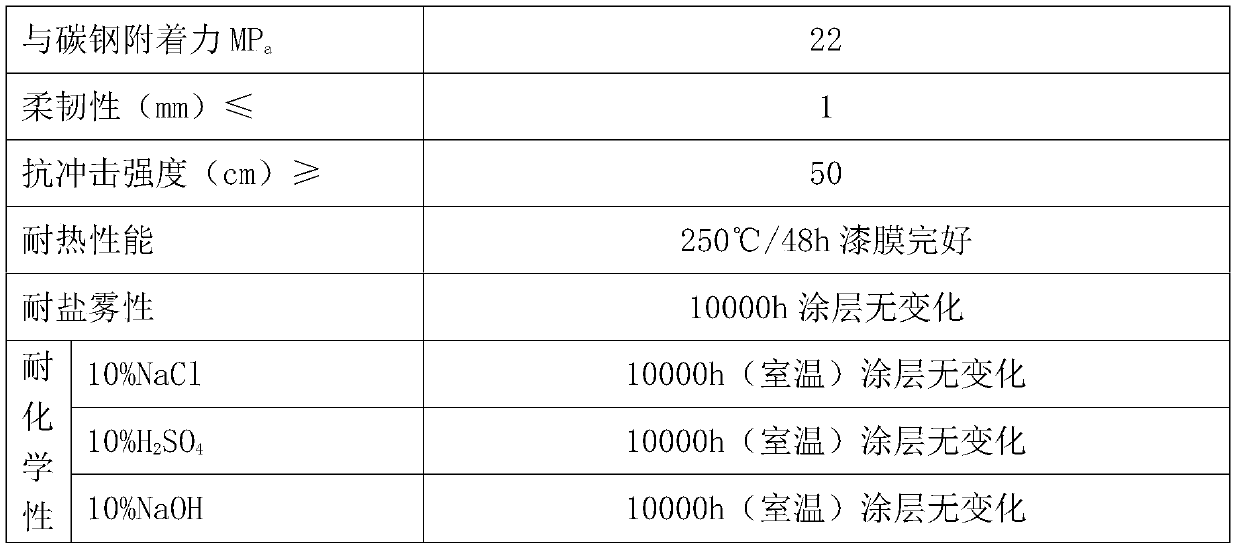

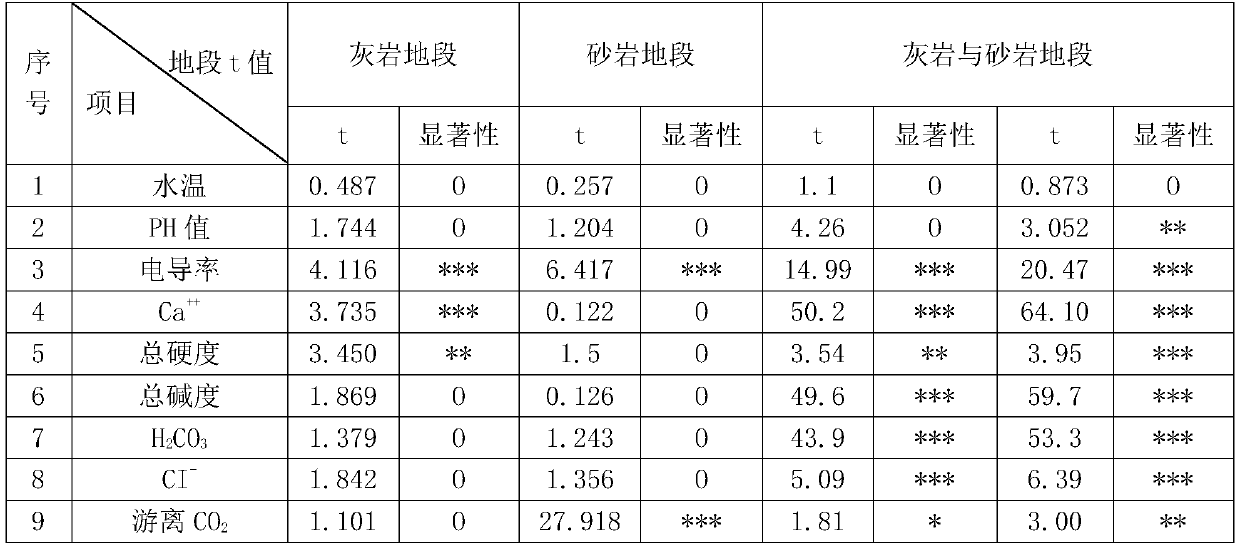

[0058] The study of the corrosion environment and corrosion characteristics in the tunnel provides a design basis for the design of the anti-corrosion composite membrane for the new long-term corrugated plate tunnel anti-rock burst device. The scheme design, material selection, formula, performance, process and treatment method of the anti-corrosion composite membrane of the new long-term corrugated plate tunnel anti-rock burst device, using the super acid-resistant, alkali-resistant and salt-resistant functions of nano-anti-corrosion materials, in the new long-term corrugated plate The surface of the anti-corrosion composite film of the anti-corrosion device of the plate tunnel rockburst device forms a nanofiber high-performance heavy-duty anti-corrosion "metal-plastic" composite film protective layer, which makes it have a long corrosion resistance of acid, alkali, salt, water vapor and harmful substances, and adapts to The special tunnel corrosion environment in the tunnel c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com