A kind of polycarboxylate photocatalytic self-cleaning waterborne polyurethane coating and its preparation and application

A water-based polyurethane, polycarboxylate technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor cleaning effect of polyurethane coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

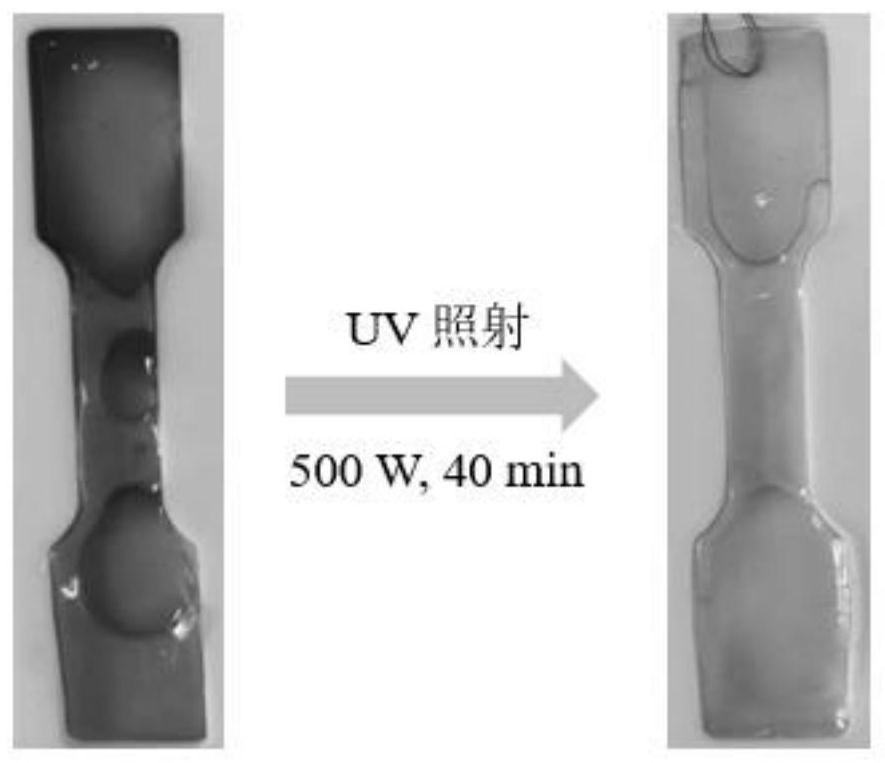

Image

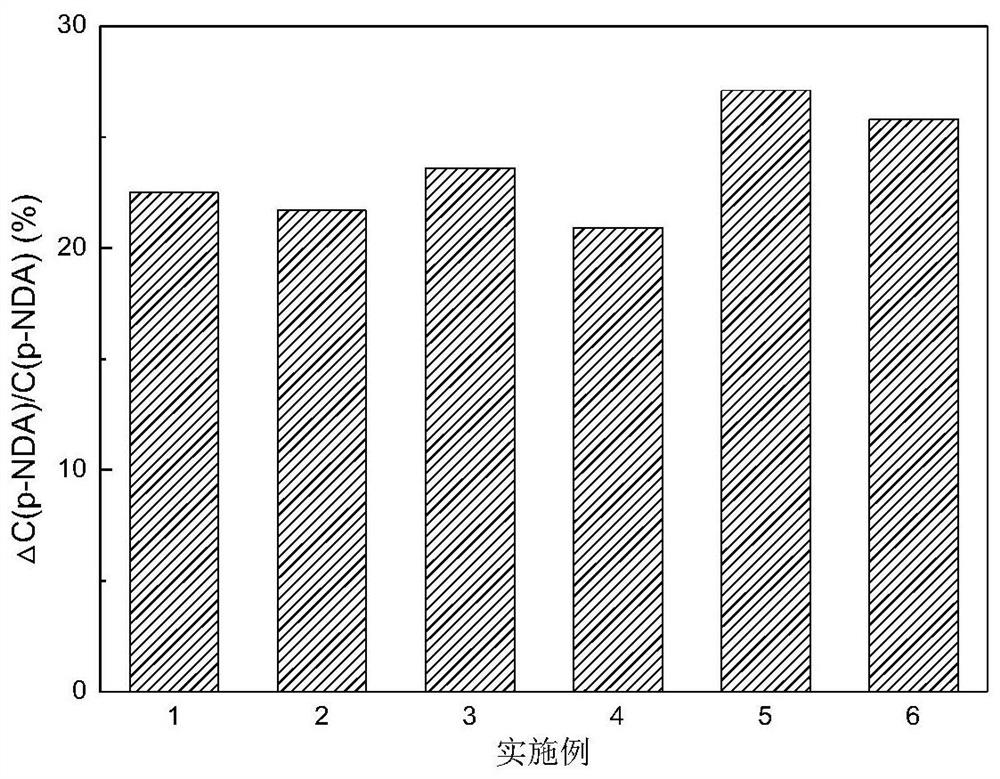

Examples

Embodiment 1

[0030] (1) polybutylene adipate diol of 20 weight parts, 2 weight parts of photoactive polybenzophenone polycarboxylate polyols (PEG-BPTCD), 10 weight parts of isophorone Diisocyanate and 0.1 parts by weight of stannous octoate were reacted at 80° C. for 2 hours to obtain a waterborne polyurethane prepolymer;

[0031] Wherein, polybenzophenone polycarboxylate polyol (PEG-BPTCD) is prepared by reacting BPTCD and PEG (Mw: 2000) at a molar ratio of 1.0:1.1 at 105° C. for 2 hours. No solvent is added during the reaction.

[0032] (2) Add 3 parts by weight of N-methylpyrrolidone and 3 parts by weight of 2,2'-dimethylolpropionic acid to the polyurethane prepolymer obtained in step (1), react at 70°C for 2 hours and then add 1 part by weight of 1,4-butanediol, continue to react at 70°C for 2 hours;

[0033] (3) Add 10 parts by weight of acetone and 2 parts by weight of triethylamine to the above system, and carry out neutralization reaction at 30°C for 1 hour; after neutralization,...

Embodiment 2

[0036] (1) 30 parts by weight of polycarbonate diol, 2 parts by weight of photoactive polybenzophenone polycarboxylate polyol (PEG-BPTCD), 10 parts by weight of hexamethylene diisocyanate, and 0.2 parts by weight of dibutyltin dilaurate were reacted at 80° C. for 2 hours to obtain a waterborne polyurethane prepolymer;

[0037] Wherein, polybenzophenone polycarboxylate polyol (PEG-BPTCD) is prepared by reacting BPTCD and PEG (Mw: 2000) at a molar ratio of 1.0:1.5 at 110° C. for 2 hours. No solvent is added during the reaction.

[0038] (2) Add 2 parts by weight of N-methylpyrrolidone and 2 parts by weight of 2,2'-dimethylolpropionic acid to the polyurethane prepolymer obtained in step (1), react at 70°C for 3 hours and add 1 part by weight of 1,6-hexanediol, continue to react at 75°C for 3 hours;

[0039] (3) Add 5 parts by weight of methyl ethyl ketone and 2 parts by weight of triethylamine to the above system, and carry out neutralization reaction at room temperature for 2 ...

Embodiment 3

[0041] (1) 40 parts by weight of polycaprolactone diol, 5 parts by weight of photoactive polybenzophenone polycarboxylate polyol (PEG-BPTCD), 10 parts by weight of toluene diisocyanate and 0.2 parts by weight of The bismuth neodecanoate catalyst was reacted at 85° C. for 4 hours to obtain a waterborne polyurethane prepolymer;

[0042] Among them, polybenzophenone polycarboxylate polyol (PEG-BPTCD) is prepared by reacting BPTCD and PEG (Mw: 2000) at a molar ratio of 1.0:2.0 at 110° C. for 2 hours. No solvent is added during the reaction.

[0043] (2) Add 5 parts by weight of N-methylpyrrolidone and 2 parts by weight of 2,2'-dimethylolpropionic acid to the polyurethane prepolymer obtained in step (1), react at 80°C for 2 hours and add 2 parts by weight of diethylene glycol, continue to react for 3 hours at 75°C;

[0044] (3) Add 10 parts by weight of methyl ethyl ketone and 3 parts by weight of triethylamine to the above system, and carry out neutralization reaction at 30°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com