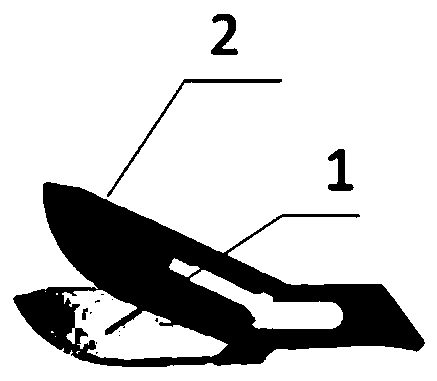

Diamond film surgical instrument and preparation method thereof

A diamond film and surgical instrument technology, applied in the field of medical instruments, can solve the problems of weak adhesion between diamond film and surgical instruments and affect the performance of surgical instruments, and achieve high hardness, excellent wear resistance, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Substrate cleaning

[0027] Place the processed instrument body in acetone for 30 minutes, then rinse it with water, place it in a mixed aqueous solution of (15%) hydrochloric acid / (20%) hydrogen peroxide, ultrasonically clean it for 30 minutes, and then wash it with distilled water After cleaning, put it in (8%) potassium hydroxide / (10%) potassium ferricyanide mixed aqueous solution for ultrasonic cleaning for 30 minutes, then wash it with distilled water, dry it, and put it in a dust-free container, device, etc. for standby;

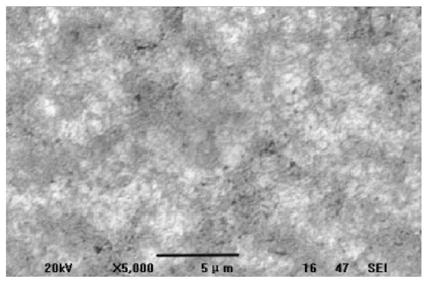

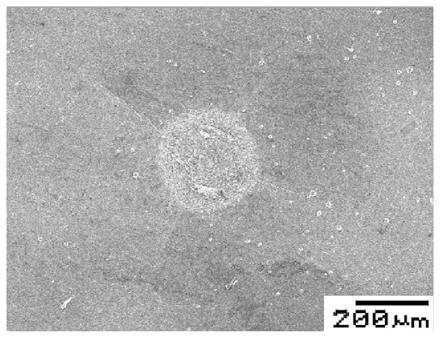

[0028] (2) Magnetron sputtering deposition of diamond film adhesion layer

[0029] Use 99.9% pure graphite as the target material, place the target material and the cleaned substrate, and control the vacuum degree of the system at 8×10 -4 Pa, the argon flow rate is controlled at 30 sccm, the bias voltage is controlled at -120V, after sputtering deposition for 3 hours, stop sputtering and cool for 60 minutes, take out the processed surgical ...

Embodiment 2

[0039] (1) Substrate cleaning

[0040] Place the processed instrument body in acetone for 20 minutes for ultrasonic cleaning, then rinse it with water, place it in (3.5%) hydrochloric acid / (25%) hydrogen peroxide mixed aqueous solution, ultrasonically clean it for 20 minutes, and then wash it with distilled water After cleaning, put it in (1%) potassium hydroxide / (15%) potassium ferricyanide mixed aqueous solution for ultrasonic cleaning for 20 minutes, then wash it with distilled water, dry it, and put it in a dust-free container, device, etc. for standby;

[0041] (2) Deposition of diamond film adhesion layer

[0042] Use 99.9% pure graphite as the target material, place the target material and the cleaned substrate, and control the vacuum degree of the system at 5×10 -4 Pa, the argon flow rate is controlled at 20 sccm, the bias voltage is controlled at -200V, after sputtering deposition for 2 hours, stop sputtering and cool for 45 minutes, take out the processed surgical i...

Embodiment 3

[0051] (1) Substrate cleaning

[0052] Place the processed instrument body in acetone for ultrasonic cleaning for 15 minutes, then rinse it with clean water, place it in (20%) hydrochloric acid / (15%) hydrogen peroxide mixed aqueous solution, ultrasonically clean it for 15 minutes, and then wash it with distilled water After cleaning, put it in (10%) potassium hydroxide / (3%) potassium ferricyanide mixed aqueous solution for ultrasonic cleaning for 15 minutes, then wash it with distilled water, dry it, and put it in a dust-free container, device, etc. for standby;

[0053] (2) Deposition of diamond film adhesion layer

[0054] Use 99.9% pure graphite as the target material, place the target material and the cleaned substrate, and control the vacuum degree of the system at 10×10 -4 Pa, the argon flow rate is controlled at 50 sccm, the bias voltage is controlled at -50V, after sputtering deposition for 8 hours, stop sputtering and cool for 60 minutes, take out the processed surgi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com