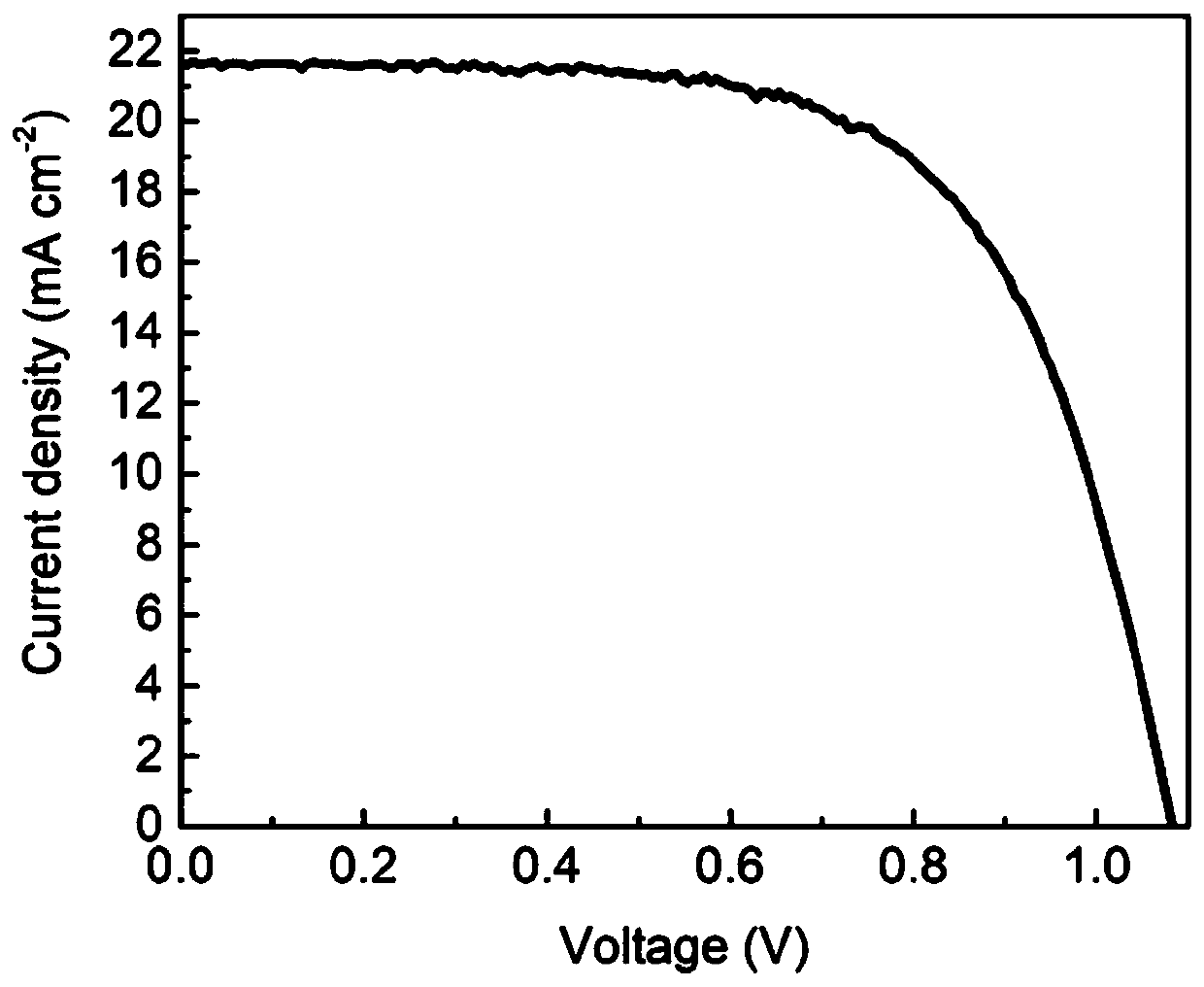

Graphene aerogel-based laminated perovskite solar cell and preparation thereof

A technology of graphene airgel and solar cells, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of fewer batteries, and achieve the effect of simple structure, simplified structure, and improved interface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Take 20ml of graphene oxide solution with a concentration of 2mg / ml, add 200mg of ascorbic acid, after ultrasonication, put it in a reaction kettle at 95°C for 3h for reduction, and vacuum freeze-dry to prepare graphene airgel;

[0042] (2) Graphene airgel 20mg obtained in step (1) is transferred in the agate mortar, adds 4ml ethanol and grinds into paste;

[0043] (3) Sequentially spin-coat TiO on the FTO conductive substrate 2 layer and ZrO 2 The insulating layer is then subjected to high-temperature annealing treatment, the sintering temperature is 500° C., and the sintering time is 30 minutes.

[0044] (4) Add pasty graphene airgel slurry (coating thickness is 10 μm) on the surface after sintering in step (3), and heat at 100°C for 10min to form a graphene airgel film layer;

[0045] (5) Coating 20 μl concentration on the graphene airgel film layer formed after heating in step (4) is 1.0MCH 3 NH 3 PB 2 The Br perovskite precursor solution was annealed at 60...

Embodiment 2

[0051] (1) Take 20ml of graphene oxide solution with a concentration of 10mg / ml, carry out high-temperature reduction, put it in a reaction kettle for 3h at 180°C, and vacuum freeze-dry to prepare graphene airgel;

[0052] (2) Graphene airgel 40mg obtained in step (1) is transferred in the agate mortar, adds 2ml ethanol and grinds into paste;

[0053] (3) Sequentially spin-coat TiO on the FTO conductive substrate 2 layer and ZrO 2 The insulating layer is then subjected to high-temperature annealing treatment, the sintering temperature is 400° C., and the sintering time is 45 minutes.

[0054] (4) Add pasty graphene airgel slurry (coating thickness is 20 μm) on the surface after sintering in step (3), and heat at 50°C for 20min to form a graphene airgel film layer;

[0055] (5) Coating 20 μl concentration on the graphene airgel film layer formed after heating in step (4) is 1.5MCH 3 NH 3 PB 2.5 Br 0.5 The perovskite precursor solution was annealed at 80 °C for 20 min and ...

Embodiment 3

[0058] (1) Take 20ml of graphene oxide solution with a concentration of 5mg / ml, carry out high-temperature reduction, put it in a reaction kettle for 3h at 180°C, and vacuum freeze-dry to prepare graphene airgel;

[0059] (2) Graphene airgel 10mg obtained in step (1) is transferred in the agate mortar, adds 1ml ethanol and grinds into paste;

[0060] (3) Sequentially spin-coat TiO on the FTO conductive substrate 2 layer and Al 2 o 3 The insulating layer is then subjected to high-temperature annealing treatment, the sintering temperature is 450° C., and the sintering time is 30 minutes.

[0061] (4) Add pasty graphene airgel slurry (coating thickness is 15 μm) on the surface after sintering in step (3), and heat at 80°C for 15min to form a graphene airgel film layer;

[0062] (5) Coating 20 μl concentration on the graphene airgel film layer formed after heating in step (4) is 1.5MCH 3 NH 3 PB 3 The perovskite precursor solution was annealed at 80 °C for 20 min and cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com