A kind of dispersion method of nano silicon

A technology of nano-silicon and nano-silicon powder, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of improving cycle performance, improving electrochemical performance, and good dispersion structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The method for dispersing the nano-silicon provided by the present embodiment comprises the following steps:

[0035] (1) Crushing the coarse silicon powder by air flow to micro silicon powder with an average particle size of 3-5 μm;

[0036] (2) Dissolving microsilica powder in absolute ethanol, and stirring to form a silicon solution with a solid content of 15%;

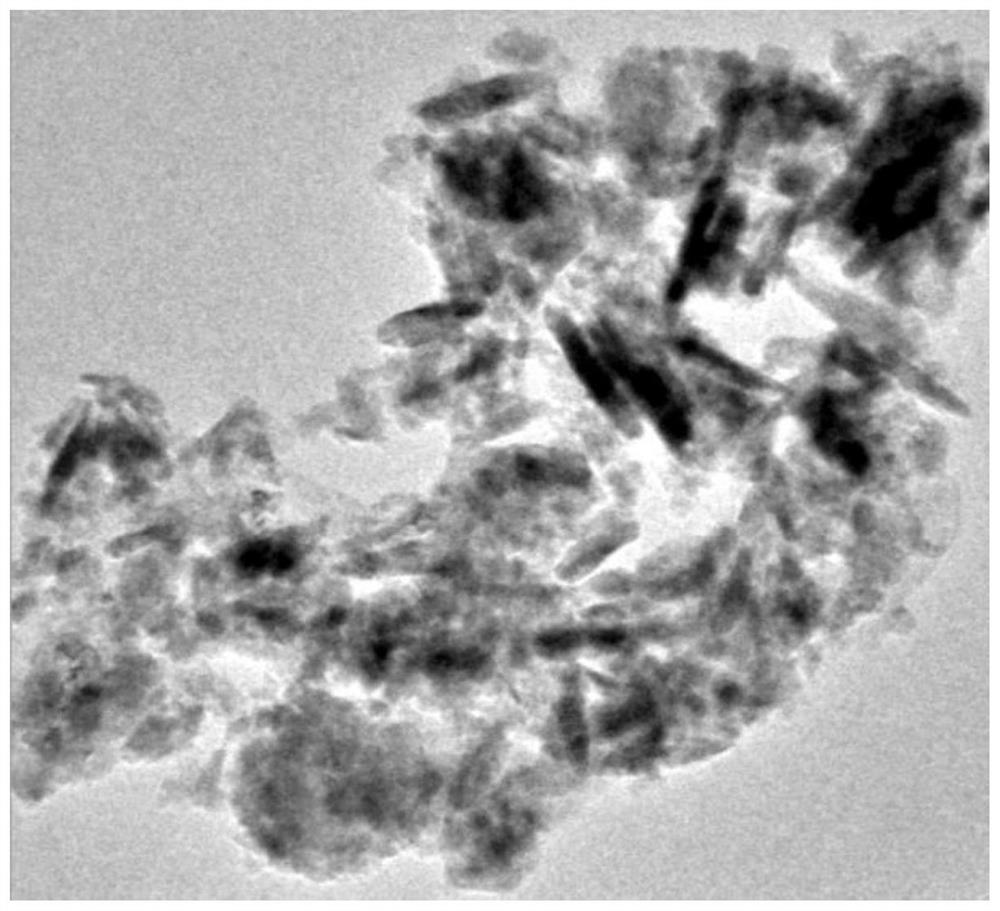

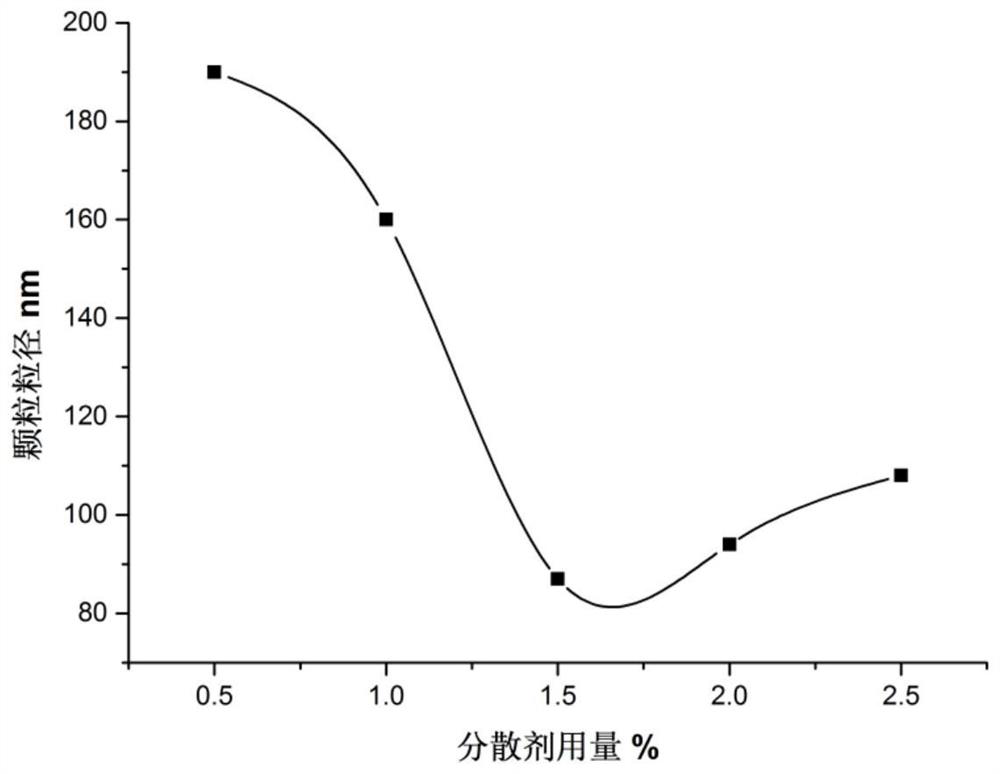

[0037] (3) The silicon solution is ball-milled by wet ball-milling process, the ball-to-material ratio of the ball mill is 3:1, the diameter of the ball-milling medium is 1mm, the ball-milling speed is 1200r / min, the ball-milling time is 8h, the ball-milling temperature is 28°C, and during the ball-milling process, add The total amount of silicon solution is 1.5% cetyltrimethylammonium bromide ion dispersant, and the nanometer silicon powder can be obtained after ball milling. The measured particle size of the nano-silicon powder is 85nm, and its transmission electron microscope picture is as follows figur...

Embodiment 2

[0039] The method for dispersing the nano-silicon provided by the present embodiment comprises the following steps:

[0040] (1) Crushing the coarse silicon powder by air flow to micro silicon powder with an average particle size of 3-5 μm;

[0041] (2) Dissolving microsilica powder in absolute ethanol, and stirring to form a silicon solution with a solid content of 15%;

[0042] (3) The silicon solution is ball-milled by wet ball-milling process, the ball-to-material ratio of the ball mill is 3:1, the diameter of the ball-milling medium is 1mm, the ball-milling speed is 1200r / min, the ball-milling time is 8h, the ball-milling temperature is 26°C, and during the ball-milling process, add The total amount of silicon solution is 0.5% cetyltrimethylammonium bromide ion dispersant, and the nanometer silicon powder can be obtained after ball milling.

Embodiment 3

[0044] The method for dispersing the nano-silicon provided by the present embodiment comprises the following steps:

[0045] (1) Crushing the coarse silicon powder by air flow to micro silicon powder with an average particle size of 3-5 μm;

[0046] (2) Dissolving microsilica powder in absolute ethanol, and stirring to form a silicon solution with a solid content of 15%;

[0047] (3) The silicon solution is ball-milled by wet ball-milling process, the ball-to-material ratio of the ball mill is 3:1, the diameter of the ball-milling medium is 1mm, the ball-milling speed is 1200r / min, the ball-milling time is 8h, the ball-milling temperature is 27°C, and during the ball-milling process, add The total amount of silicon solution is 1% hexadecyltrimethylammonium bromide ion dispersant, and the nanometer silicon powder can be obtained after ball milling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com