Cold-mixed colored asphalt cementing material and preparation method thereof

A technology for colored asphalt and cementitious materials, which is applied in building thermal insulation materials, building components, building structures, etc., can solve the problems of poor pigment adhesion and easy decolorization, technical difficulty, and poor rutting resistance, etc., to improve compatibility. , Improve the working environment, not easy to discolor and decolorize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In addition, the present invention also provides a method for preparing the above-mentioned cold-mix colored asphalt binder, comprising the following steps:

[0031] Step 1: After heating the aqueous dispersion of the porous material, add an anionic surfactant and an inorganic pigment, stir thoroughly, filter, and dry to obtain a modified color pigment; preferably, heat the emulsion to 80°C, and the stirring time is 15-45 minutes.

[0032] Step 2: After adding optional nano-calcium carbonate, nano-silica or nano-titanium dioxide into the dispersant for uniform dispersion, add a surface modifier, then heat, stir, evaporate and remove the dispersant, and obtain a modified inorganic nano-reinforced agent; preferably, ethanol is used as the dispersant, the heating temperature is 60-80° C., and the stirring time is 1-2 hours.

[0033] Step 3: Add optional SBS resin, styrene-butadiene rubber or polybutadiene rubber to the decolorized asphalt, heat and swell, and grind in a c...

Embodiment 1

[0039] The preparation method of the cold-mix colored permeable asphalt binder in this embodiment comprises the following steps:

[0040] The first step is to prepare modified color pigments

[0041] The pigment is iron oxide red (Fe 2 o 3 ). Disperse 70g of molecular sieves in water to make an emulsion, stir well and heat to 80°C, then add 3g of sodium fatty acid modifier, stir fully for 3min, then add 27g of iron oxide red (Fe 2 o 3 ), stirred for 30min, then filtered, and the filter cake was dried at 105°C as a modified color pigment.

[0042] The second step is to prepare modified inorganic nano-reinforcing agent

[0043]Using ethanol as a dispersant, add 80g of nano-calcium carbonate to 200mL of ethanol, stir fully to disperse the nano-calcium carbonate evenly, then add 2.4g of sodium dodecylbenzenesulfonate to the nano-calcium carbonate emulsion, and heat up to 80°C, and Stir for 1.5 hours, evaporate 70-85% of the ethanol to prepare a modified inorganic nano-reinfo...

Embodiment 2 to 3

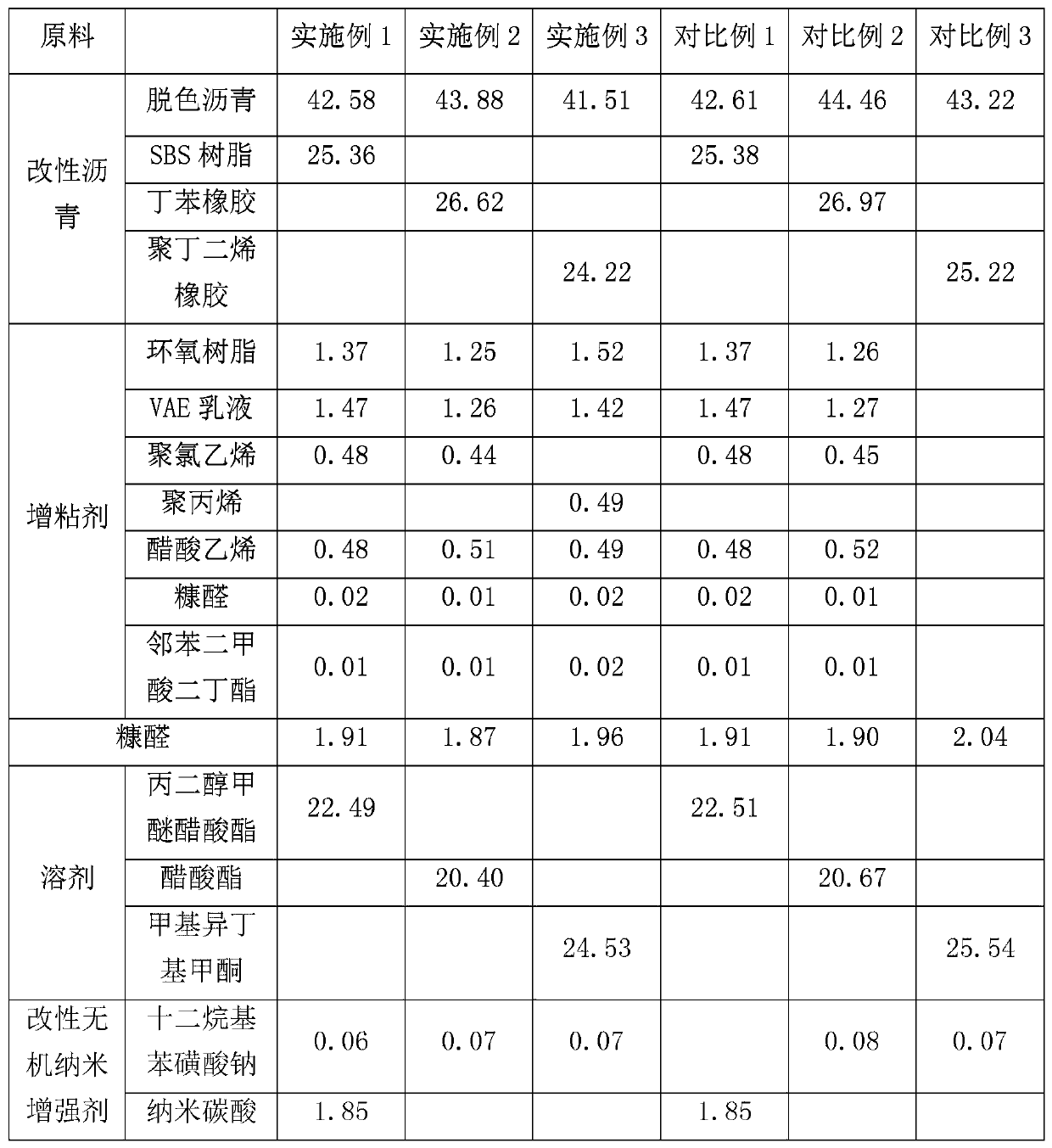

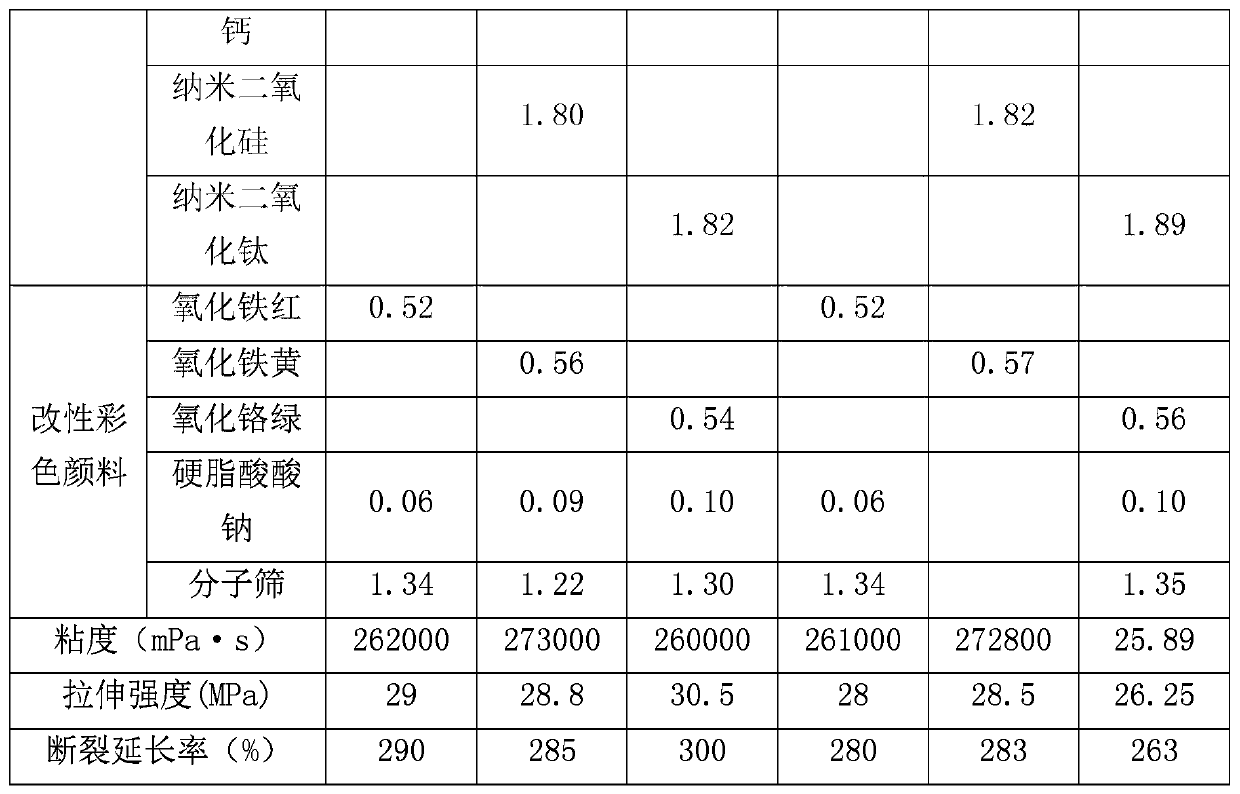

[0052] Similar to the preparation method of Example 1, Examples 2 to 3 used the amount of raw materials shown in Table 1 to prepare cold-mix colored asphalt binder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com