Austempered ductile iron and preparation method and application thereof

A technology of austempered ductile iron and molten iron, which is applied in the field of austempered ductile iron and its preparation, can solve the problems of decreased strength of castings, long cooling time, poor hardenability, etc., and can improve elongation, mechanical properties, and yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

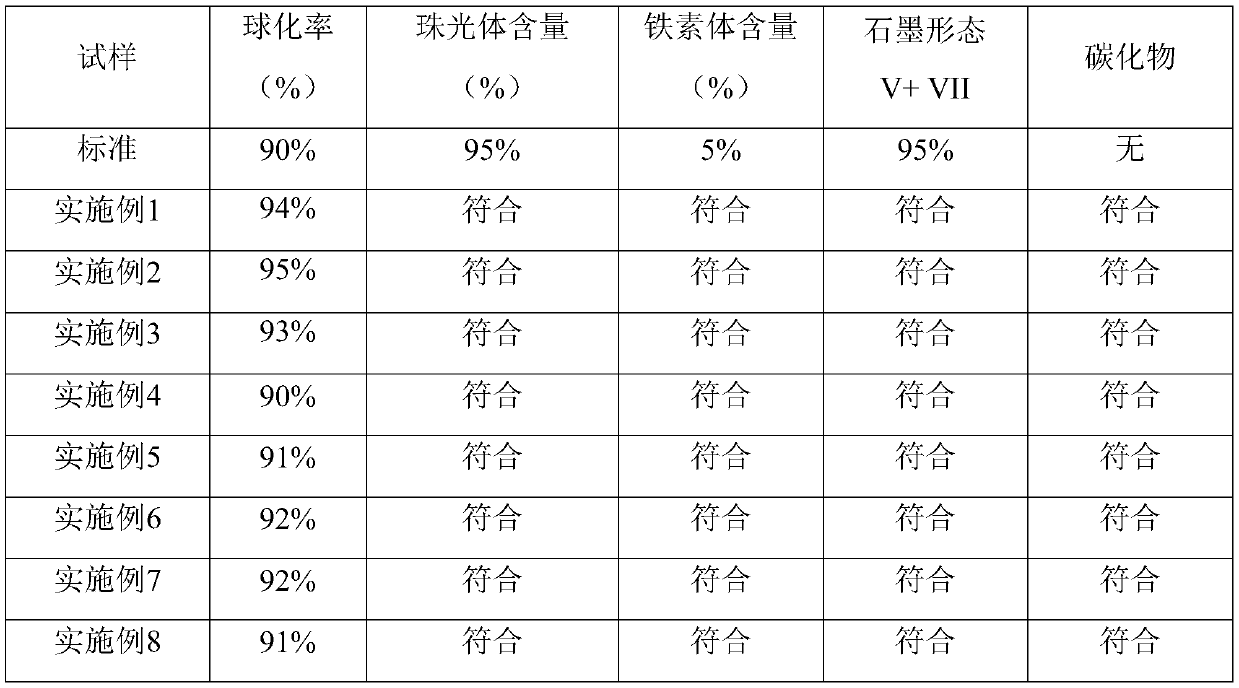

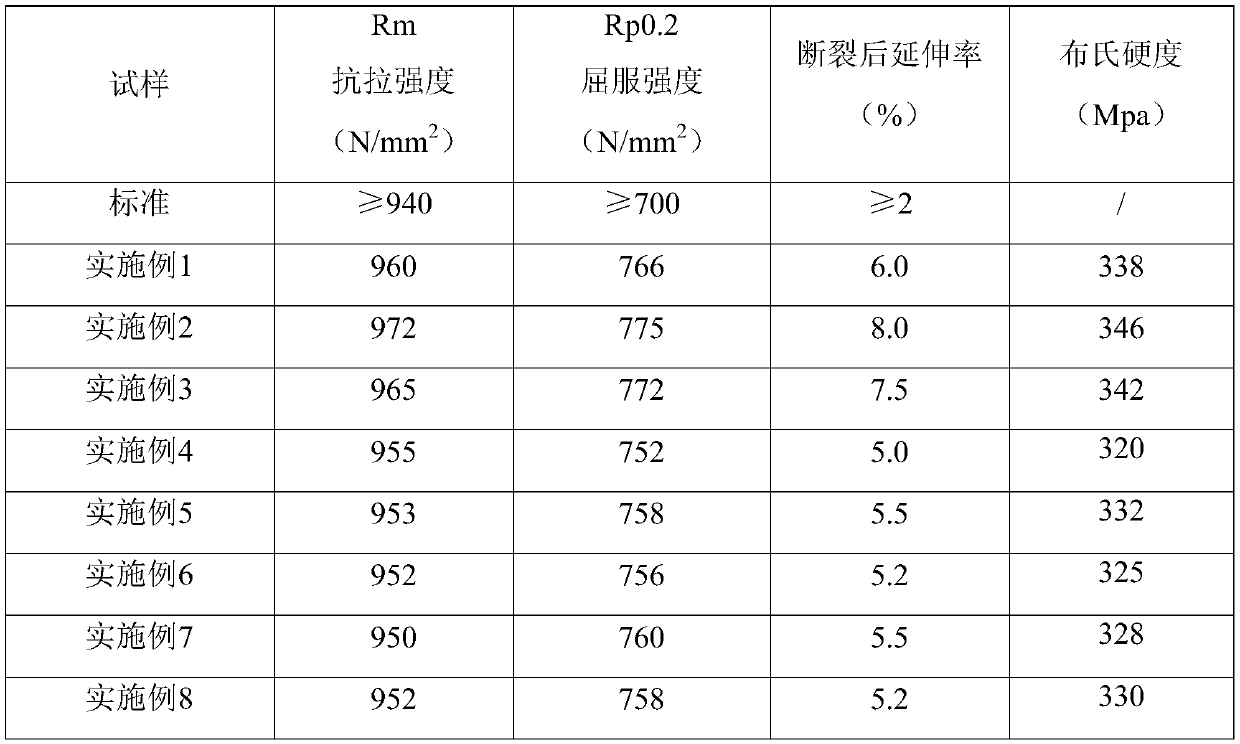

Examples

Embodiment 1

[0046] A kind of Aubic ductile iron, including the following elements by mass percentage: C 3.35%, Si 2.45%, Mn 0.21%, Ni 2.3%, Cu 0.69%, Mo 0.32%, Mg 0.05%, P≤0.02%, S≤ 0.02%, and the balance is Fe.

[0047] The preparation method comprises the following steps:

[0048] a. Raw material smelting:

[0049] Mix and melt pig iron, scrap steel, furnace charge, recarburizer, silicon carbide, and silicon at a melting temperature of 1500°C to obtain molten iron, then let it stand for 1 minute, remove slag, and wait for the temperature of molten iron to drop to 1470°C; among them, The weight ratio of pig iron:scrap:return charge is 10:70:20;

[0050] b. Spheroidization treatment and inoculation treatment:

[0051] b1. Spheroidization treatment and primary inoculation treatment: add a primary inoculant with a total weight of 0.35% of the molten iron in the bag, the particle size of the primary inoculant is 3mm, add a nodulizer with a total weight of 1.2% of the molten iron, and the ...

Embodiment 2

[0059] An Aubic ductile iron, including the following elements by mass percentage: C 3.4%, Si 2.4%, Mn 0.22%, Ni 2.1%, Cu 0.75%, Mo 0.3%, Mg 0.06%, P≤0.02%, S≤ 0.02%, and the balance is Fe.

[0060] The preparation method comprises the following steps:

[0061] a. Raw material smelting:

[0062] Mix and melt pig iron, scrap steel, furnace charge, recarburizer, silicon carbide, and silicon at a melting temperature of 1520°C to obtain molten iron, then let it stand for 1 minute, remove slag, and wait for the temperature of the molten iron to drop to 1480°C; among them, The weight ratio of pig iron:scrap:return charge is 15:60:25;

[0063] b. Spheroidization treatment and inoculation treatment:

[0064] b1. Spheroidization treatment and primary inoculation treatment: add a primary inoculant with a total weight of 0.4% of molten iron in the bag, the particle size of the primary inoculant is 5mm, add a nodulizer with a total weight of 1.1% of molten iron, and a particle size of ...

Embodiment 3

[0072] An Aubic ductile iron, including the following elements by mass percentage: C 3.44%, Si 2.37%, Mn 0.23%, Ni2%, Cu 0.8%, Mo 0.25%, Mg 0.07%, P≤0.02%, S≤0.02% , The balance is Fe.

[0073] The preparation method comprises the following steps:

[0074] a. Raw material smelting:

[0075] Mix and melt pig iron, scrap steel, furnace charge, recarburizer, silicon carbide, and silicon at a melting temperature of 1550°C to obtain molten iron, then let it stand for 1 minute, remove slag, and wait for the temperature of molten iron to drop to 1490°C; among them, The weight ratio of pig iron:scrap:return charge is 20:50:30;

[0076] b. Spheroidization treatment and inoculation treatment:

[0077] b1. Spheroidization treatment and primary inoculation treatment: add a primary inoculant of 0.45% of the total weight of the molten iron in the bag, the particle size of the primary inoculant is 8mm, add a nodulizer of 1% of the total weight of the molten iron, and the particle size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com