Indium aluminum zinc oxide thin film transistor based on gate dielectric layer with high dielectric constant and full room temperature preparation method thereof

An oxide thin film, high dielectric constant technology, used in transistors, semiconductor/solid-state device manufacturing, circuits, etc., can solve difficult problems, and achieve the effect of strong experimental repeatability and detailed and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

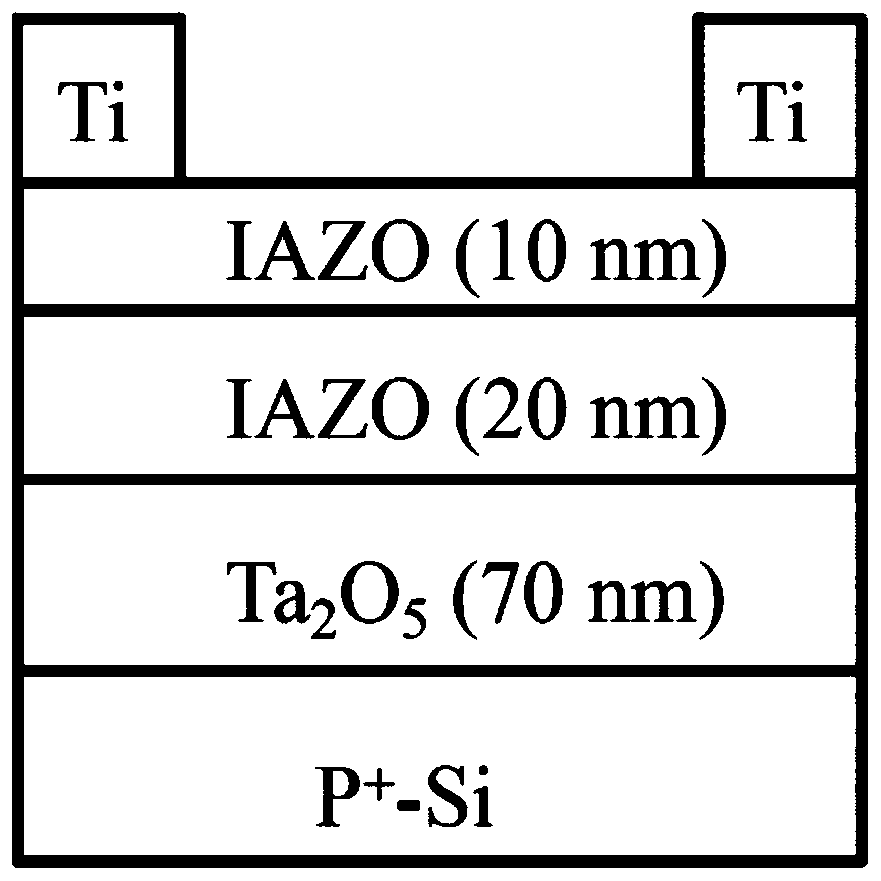

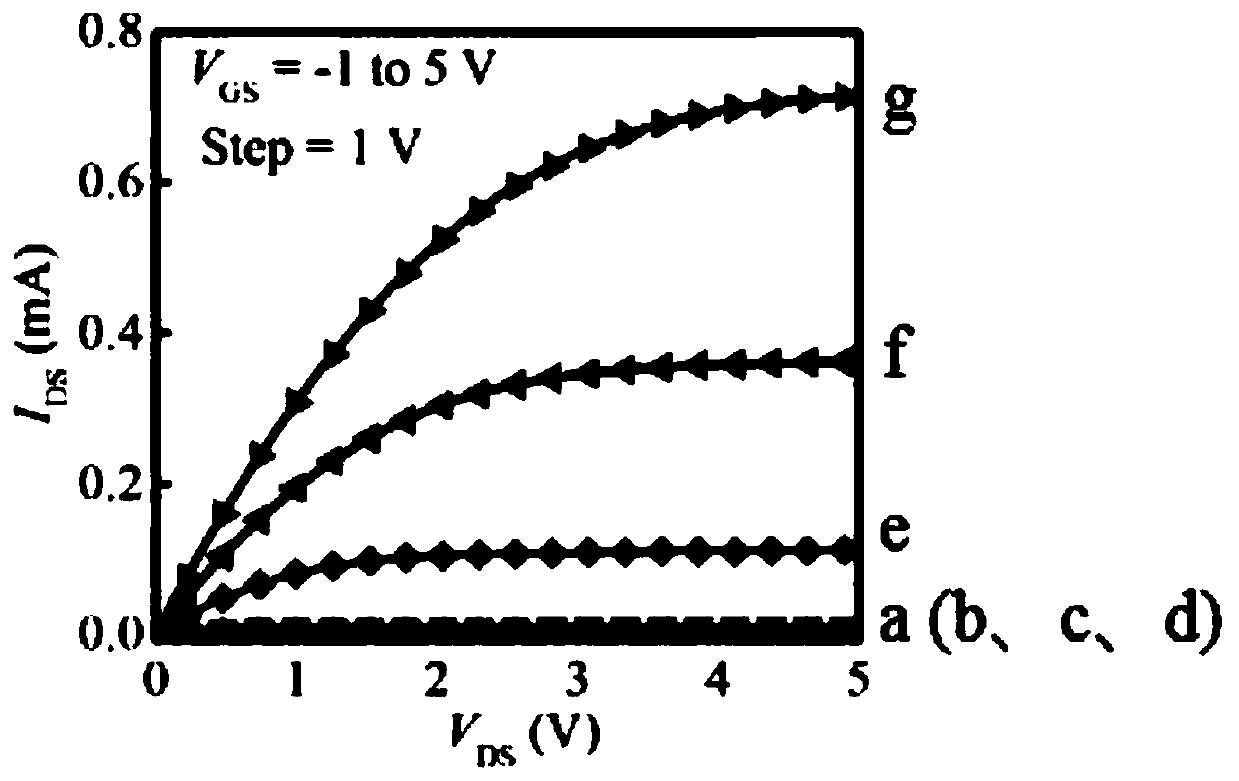

[0067] An indium aluminum zinc oxide thin film transistor based on a high dielectric constant gate dielectric layer, including P + -Si substrate, Ta 2 o 5 Gate dielectric layer, double active layer, source electrode and drain electrode, the double active layer includes the first layer of IAZO film and the second layer of IAZO film arranged in sequence from bottom to top, and the source electrode and drain electrode are grown on the second layer on IAZO film.

[0068] Ta 2 o 5 Has a high dielectric constant, Ta 2 o 5 The dielectric constant of SiO is about 2 six times the dielectric constant, so Ta 2 o 5 The gate voltage has a stronger ability to regulate carriers, and the required operating voltage is smaller, which can effectively improve the TFT operating voltage, field effect mobility, sub-threshold swing and other characteristic parameters.

[0069] Ta 2 o 5 The thickness of the gate dielectric layer is 50-150nm;

[0070] Ta of different thickness 2 o 5 The g...

Embodiment 2

[0076] According to an indium aluminum zinc oxide thin film transistor based on a high dielectric constant gate dielectric layer provided in Embodiment 1, the difference lies in:

[0077] Ta 2 o 5 The thickness of the gate dielectric layer is 70nm.

[0078] The thickness of the first layer of IAZO film is 20nm; the thickness of the second layer of IAZO film is 10nm.

[0079] Dimensions of the channel between the source electrode and the drain electrode: 2000 μm in width and 60 μm in length.

Embodiment 3

[0081] The full room temperature preparation method of the indium aluminum zinc oxide thin film transistor based on the high dielectric constant gate dielectric layer provided in embodiment 2 includes:

[0082] (1) at P + -Grow Ta on Si substrate 2 o 5 gate dielectric layer;

[0083] (2) at Ta 2 o 5 growing the first layer of IAZO film on the gate dielectric layer;

[0084] (3) growing a second layer of IAZO film on the first layer of IAZO film;

[0085] (4) Use electron beam evaporation to grow source and drain electrodes on the second layer of IAZO thin film.

[0086] In step (1), P + -Si substrate is a polished substrate, P + - Before using the Si substrate, use Decon (Decon) cleaning agent, deionized water, acetone, and ethanol in sequence on the P + -Si substrates were cleaned and dried with nitrogen gas.

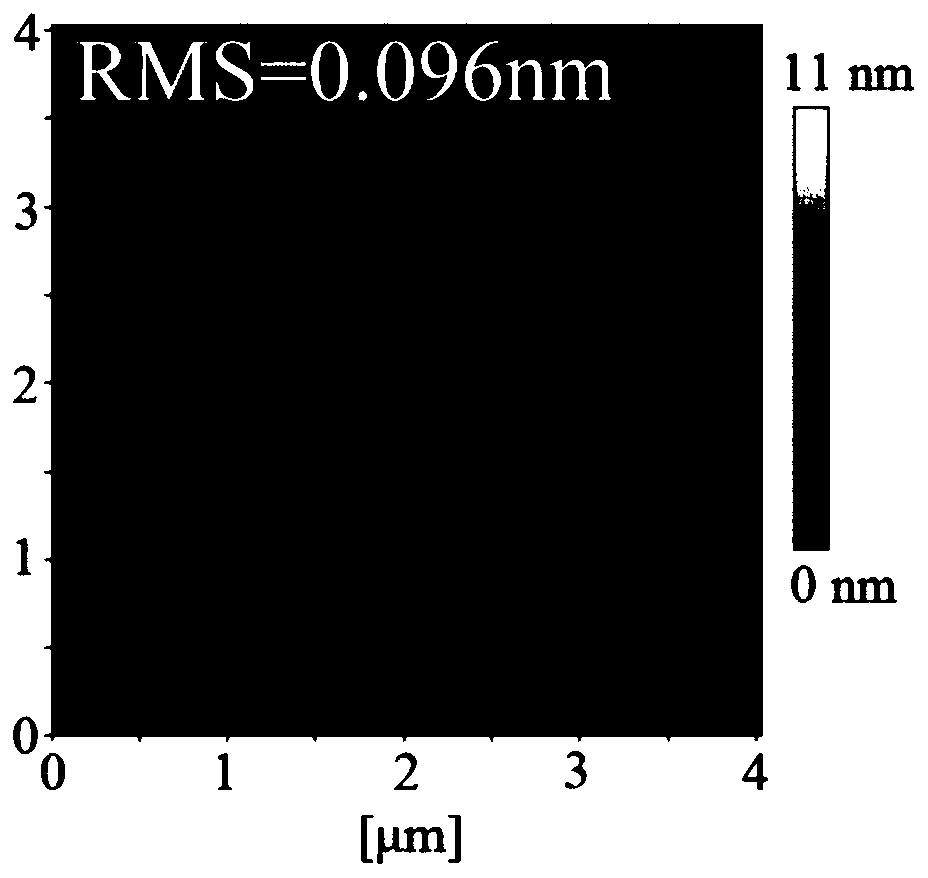

[0087] The surface of the substrate has been polished, which is conducive to the growth of Ta with high flatness. 2 o 5 gate dielectric, and P + -Si subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com