Preparation method of molecularly imprinted open tubular column

A molecular imprinting and open-column technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc. Improved selective identification, increased sensitivity, and reduced matrix interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

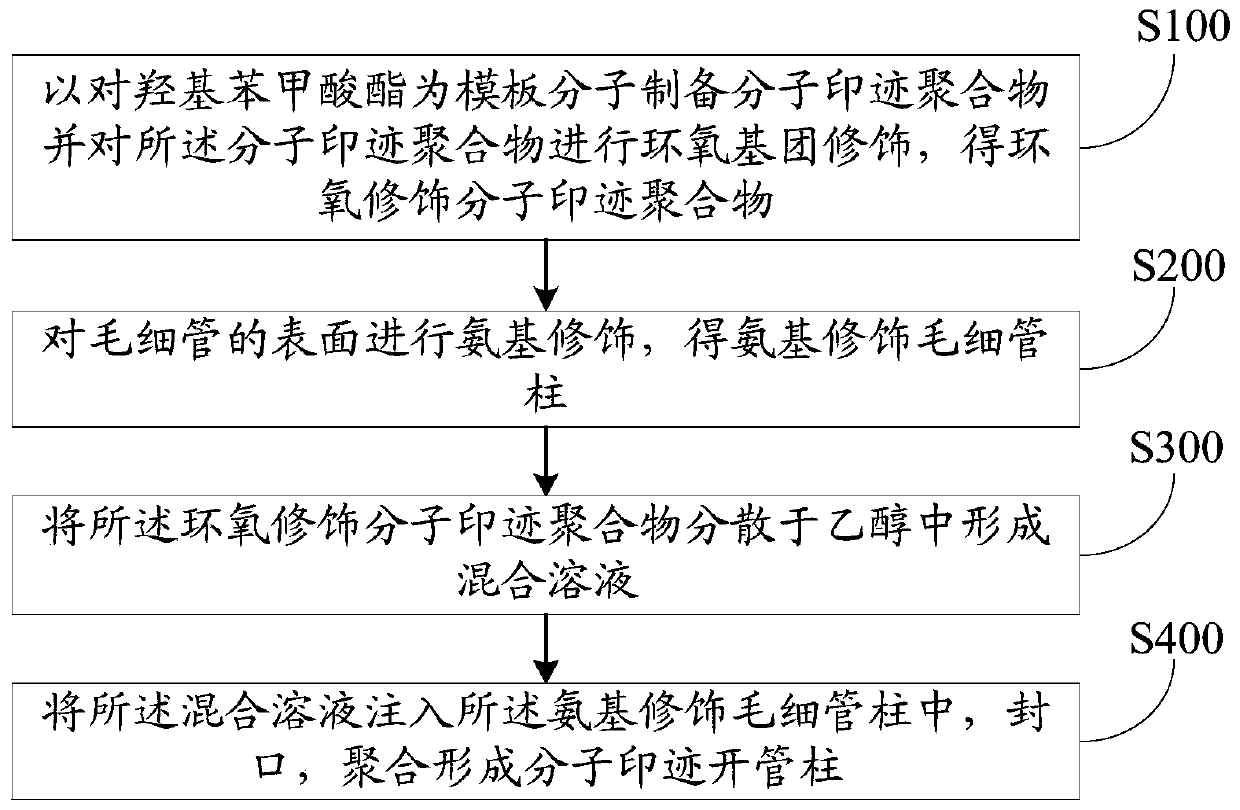

[0046] see figure 1 In an embodiment of the preparation method of the molecularly imprinted open-tubular column, the preparation method of the molecularly imprinted open-tubular column comprises the following steps:

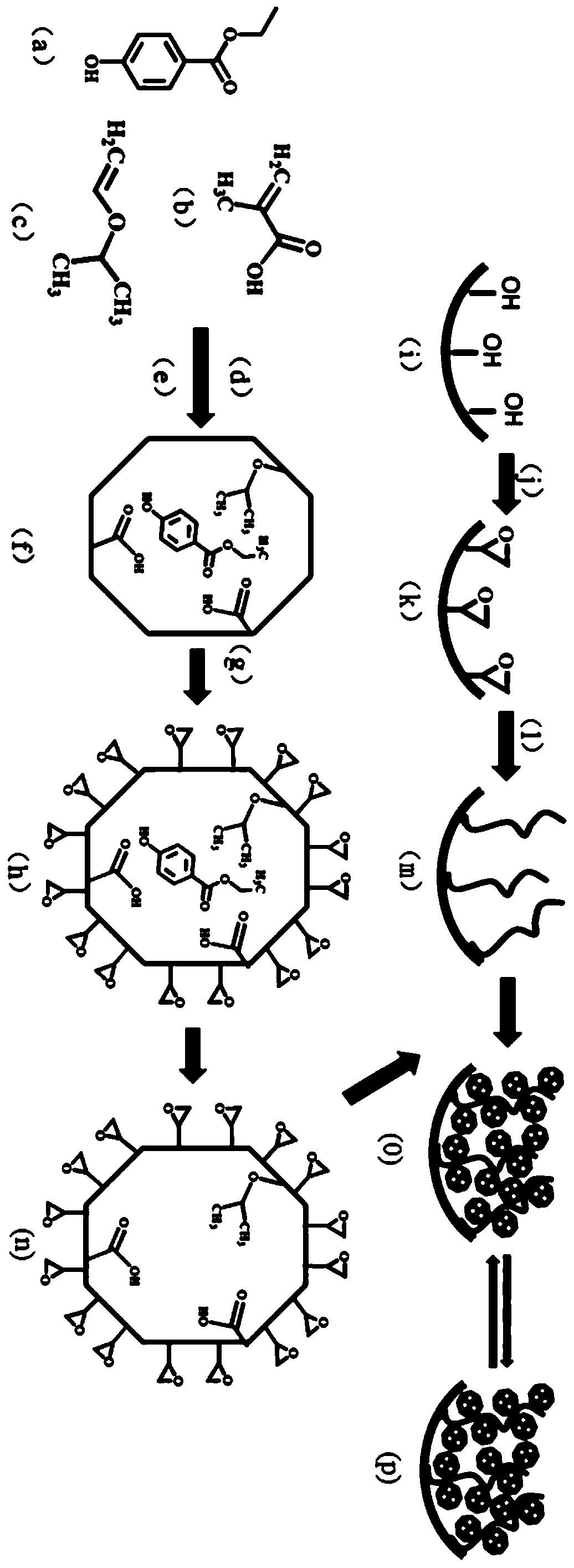

[0047] Step S100 , preparing a molecularly imprinted polymer with paraben as a template molecule and modifying the molecularly imprinted polymer with epoxy groups to obtain an epoxy-modified molecularly imprinted polymer.

[0048] Molecular imprinting technology refers to the preparation and application technology of polymers that specifically recognize specific target molecules (template molecules) and their structural analogs. Molecularly imprinted polymers (MIPs) can selectively recognize template molecules in complex systems, and have the advantages of strong resistance to harsh environments, good stability, and long service life, making up for the shortcomings of traditional solid-phase extraction methods. Insufficient, gradually become a research hotspot. ...

Embodiment 1

[0088] Add parabens and functional monomers (a mixture of methacrylic acid and isobutyl vinyl ether) into acetonitrile at a molar ratio of 5:1, prepolymerize at room temperature for 1 min, and then add a crosslinking agent Ethylene glycol dimethacrylate (the molar ratio to the functional monomer is 10:1), the initiator azobisisobutyronitrile 1 mg, nitrogen and oxygen removal for 1 min. Then placed at 50 ° C for 8 hours of polymerization reaction. At the 8th hour of the reaction, 1 mg of initiator azobisisobutyronitrile was added, followed by 20 mL of toluene solution with a mass concentration of 1 (w / w)% glycidyl methacrylate and 1 mg of initiator azobisisobutyronitrile, Continue to react for 4h. After removing the template with an organic solvent, the epoxy-modified molecularly imprinted polymer was obtained.

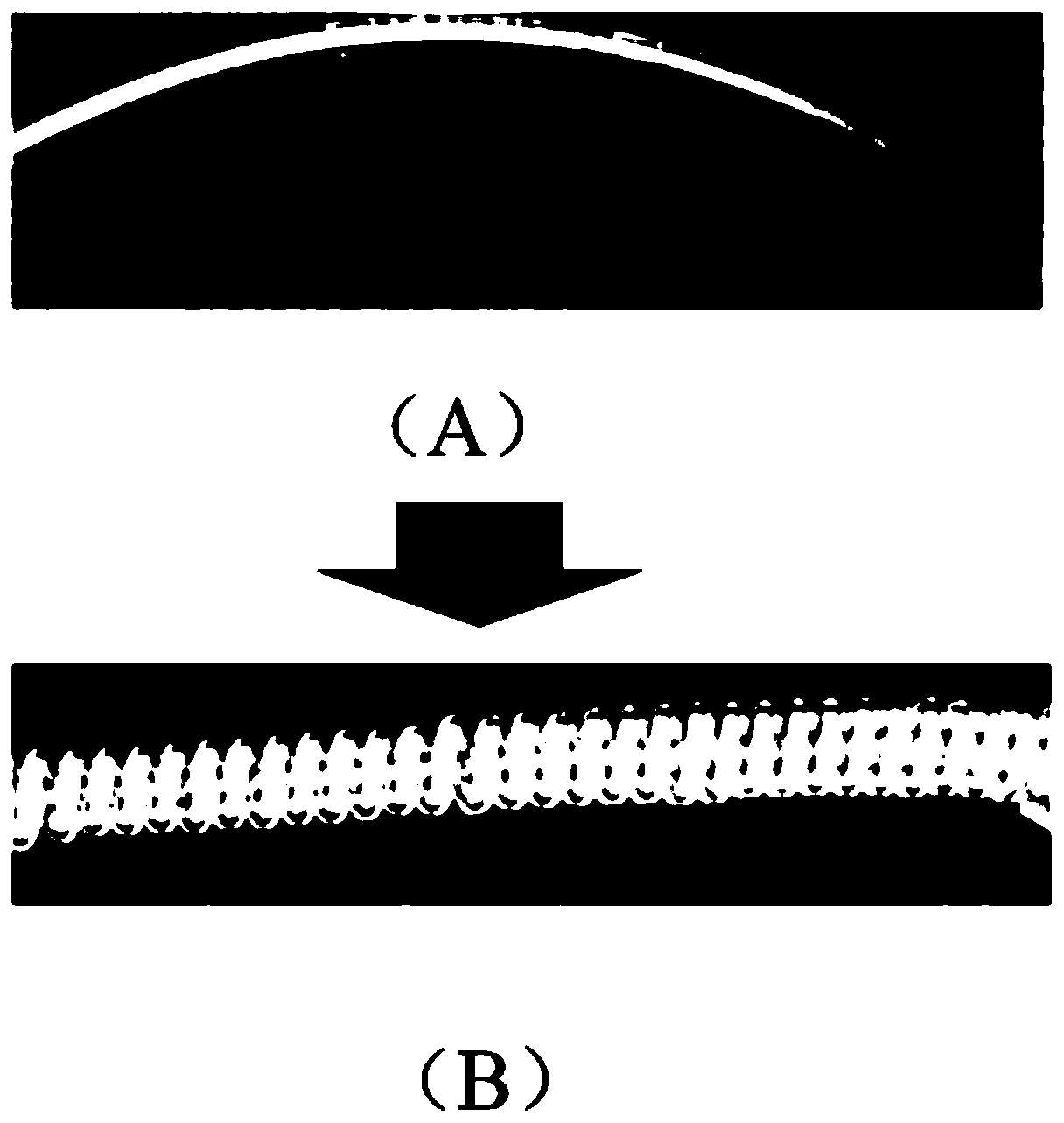

[0089] Dopamine was dissolved in Tris-HCl buffer solution to obtain a dopamine alkaline solution with a pH of 8.5, which was set aside. Take a polytetrafluoroethyle...

Embodiment 2

[0093] Add parabens and functional monomers (a mixture of methacrylic acid and isobutyl vinyl ether) to acetonitrile at a molar ratio of 10:1, prepolymerize at room temperature for 20 minutes, and then add a crosslinking agent Ethylene glycol dimethacrylate (the molar ratio to the functional monomer is 5:1), 10 mg of initiator azobisisobutyronitrile, nitrogen and oxygen removal for 5 minutes. Then placed at 60 ° C for 12 hours of polymerization reaction. At the 10th hour of the reaction, 3 mg of initiator azobisisobutyronitrile was added, followed by addition of 20 mL of toluene solution with a mass concentration of 8 (w / w)% glycidyl methacrylate and 5 mg of initiator azobisisobutyronitrile, Continue to react for 6h. After removing the template with an organic solvent, the epoxy-modified molecularly imprinted polymer was obtained.

[0094] Dopamine was dissolved in Tris-HCl buffer solution to obtain a dopamine alkaline solution with a pH of 8.5, which was set aside. Take a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com