Graded porous carbon material and supercapacitor prepared therefrom

A supercapacitor, hierarchical porous technology, applied in the field of materials and energy electrochemistry, to achieve the effect of good conductivity, high specific capacity and rate performance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] Step (1): Mix diatomaceous earth and furfuryl alcohol at a mass ratio of 1:5, stir at room temperature for 1.5 h, and heat at 95° C. for 24 h. Then it was transferred to a tube furnace and heated at 900 °C for 3 h under an argon atmosphere at a heating rate of 5 °C / min to make it completely carbonized.

[0030] Step (2): Mix the obtained template carbon and potassium hydroxide solid at a mass ratio of 1:3, activate at 700°C for 1 hour at a heating rate of 5°C / min in an argon atmosphere, and wash with dilute hydrochloric acid after cooling Wash with deionized water and dry to obtain hierarchical porous carbon materials.

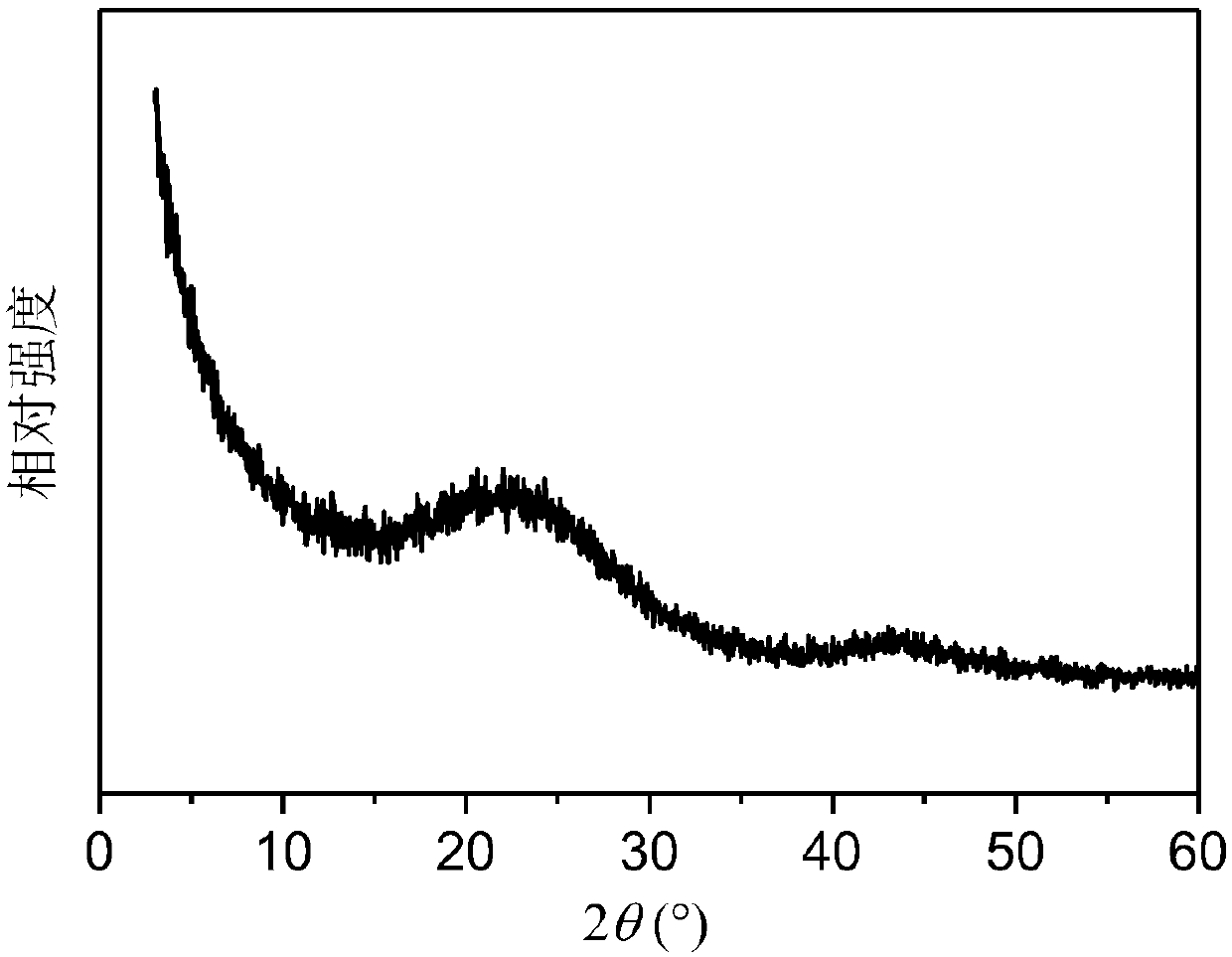

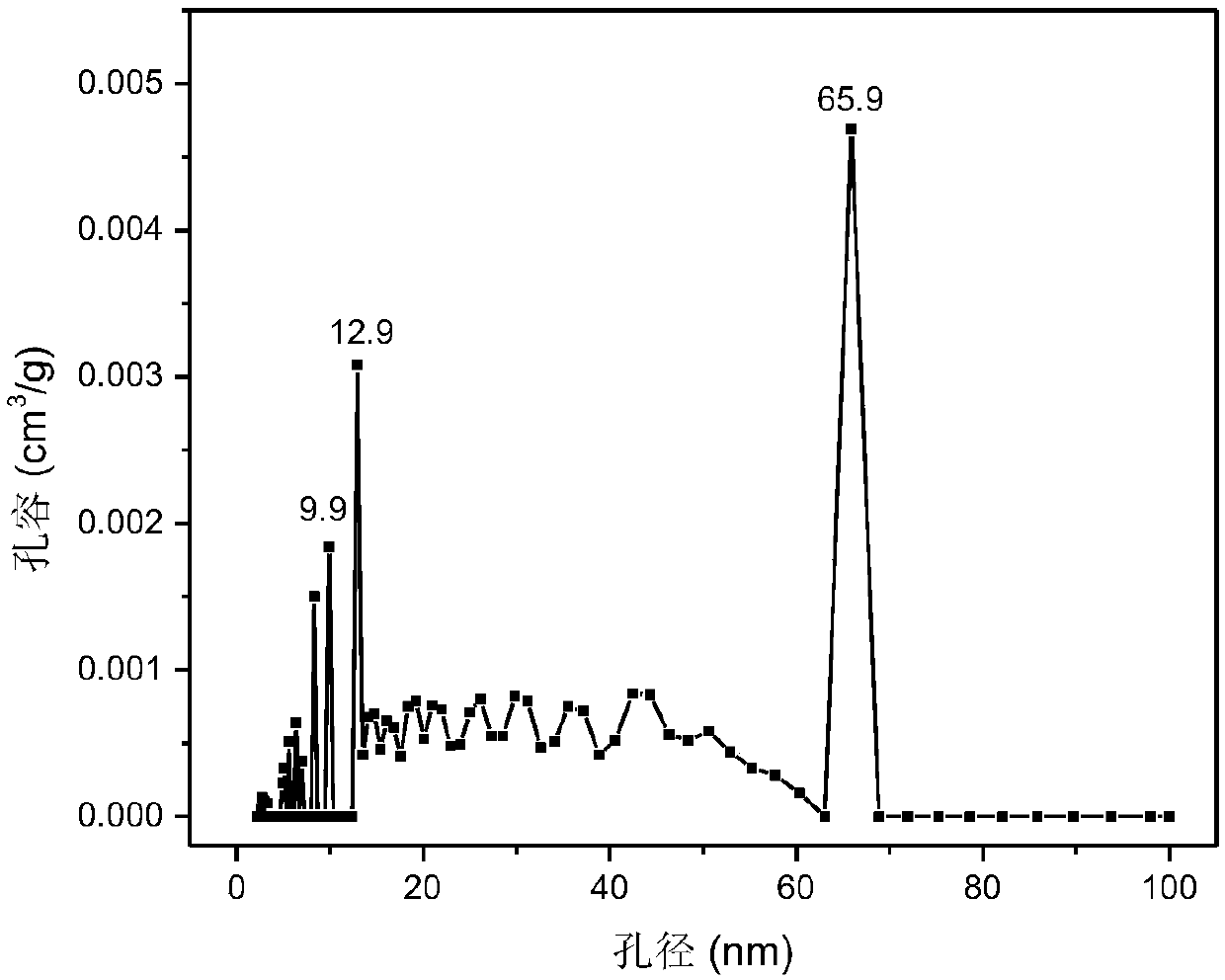

[0031] figure 1 is the X-ray diffraction pattern of the prepared hierarchical porous carbon material. There are two broad diffraction peaks at about 23° and 43°, corresponding to the (002) and (100) crystal planes of graphite respectively. After calculation, the (002) of the porous carbon material...

Embodiment 2

[0038] This embodiment includes the following steps:

[0039] Step (1): Mix diatomaceous earth and furfuryl alcohol at a mass ratio of 1:5, stir at room temperature for 1.5 h, and heat at 95° C. for 24 h. Then it was transferred to a tube furnace and heated at 900 °C for 3 h under an argon atmosphere at a heating rate of 5 °C / min to make it completely carbonized.

[0040] Step (2): Mix the obtained template carbon and potassium hydroxide solid at a mass ratio of 1:3, activate at 800°C under an argon atmosphere at a heating rate of 5°C / min for 1 hour, and then wash with dilute hydrochloric acid after cooling Wash with deionized water and dry to obtain hierarchical porous carbon materials.

[0041] The specific surface area of the prepared hierarchical porous carbon material is 854.9m 2 / g.

[0042] The prepared graded porous carbon material, conductive carbon and PTFE were mixed evenly according to the mass ratio of 80:10:10, and after the grinding was sufficient, they wer...

Embodiment 3

[0045] This embodiment includes the following steps:

[0046] Step (1): Mix diatomaceous earth and furfuryl alcohol at a mass ratio of 1:5, stir at room temperature for 1.5 h, and heat at 95° C. for 24 h. Then it was transferred to a tube furnace and heated at 900 °C for 3 h under an argon atmosphere at a heating rate of 5 °C / min to make it completely carbonized.

[0047] Step (2): Mix the obtained template carbon and potassium hydroxide solid at a mass ratio of 1:3, activate at 900°C under an argon atmosphere at a heating rate of 5°C / min for 1 hour, and rinse with dilute hydrochloric acid after cooling Wash with deionized water and dry to obtain hierarchical porous carbon materials.

[0048] The specific surface area of the prepared hierarchical porous carbon material is 1170.5m 2 / g.

[0049] The prepared graded porous carbon material, conductive carbon and PTFE were mixed evenly according to the mass ratio of 80:10:10, and after the grinding was sufficient, they were mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com