Preparation method for facilitation bone titanium tantalum composite

A composite material and bone-promoting technology, which is applied in medical science, prosthesis, tissue regeneration, etc., can solve problems such as operation failure, increased medical costs, and insufficient mechanical properties, and achieves non-cytotoxicity, does not affect cell proliferation, and has excellent The effect of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

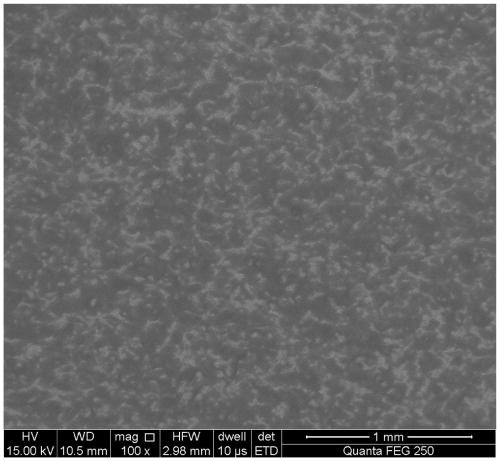

[0039] Prepare titanium-tantalum alloy powder, wherein in the titanium-tantalum alloy powder, according to the atomic ratio, titanium: tantalum = 7:3; ball mill: ball material ratio is 4:1. 1mm < ball diameter < 5mm. The amount of powder loaded at one time = 100g. Sealed ball milling, vacuuming, vacuum degree <10Pa, filled with argon as protective gas, rotating speed 150r / min, ball milling time 18h. Then place the titanium-tantalum alloy powder in a discharge plasma sintering furnace for sintering. The sintering is completed to obtain a titanium-tantalum composite material. The sintering procedure is as follows: the heating rate is 70°C / min, the sintering temperature is 1000°C, and the sintering time is 5min; the sintering pressure 60MPa, air-cooled. The titanium-tantalum composite material was polished with 400 mesh, 600 mesh, 800 mesh, and 1200 mesh sandpaper until the surface was smooth without scratches, and then ultrasonically cleaned with ethanol, acetone, and deionized...

Embodiment 2

[0058] Prepare titanium-tantalum alloy powder, in which titanium-tantalum alloy powder, according to the atomic ratio, titanium: tantalum: 2:1; sealed ball mill, vacuum, vacuum degree < 10Pa, filled with argon as protective gas, speed 150r / min , Ball milling time 15h. . Then the titanium-tantalum alloy powder is placed in a discharge plasma sintering furnace for sintering, and the sintering is completed to obtain a titanium-tantalum composite material. The sintering procedure is as follows: the heating rate is 70°C / min, the sintering temperature is 1300°C, and the sintering time is 15min; the sintering pressure 60MPa, air-cooled. The titanium-tantalum composite material was polished with 400 mesh, 600 mesh, 800 mesh, and 1200 mesh sandpaper until the surface was smooth without scratches, and then ultrasonically cleaned with ethanol, acetone, and deionized water in sequence, and dried.

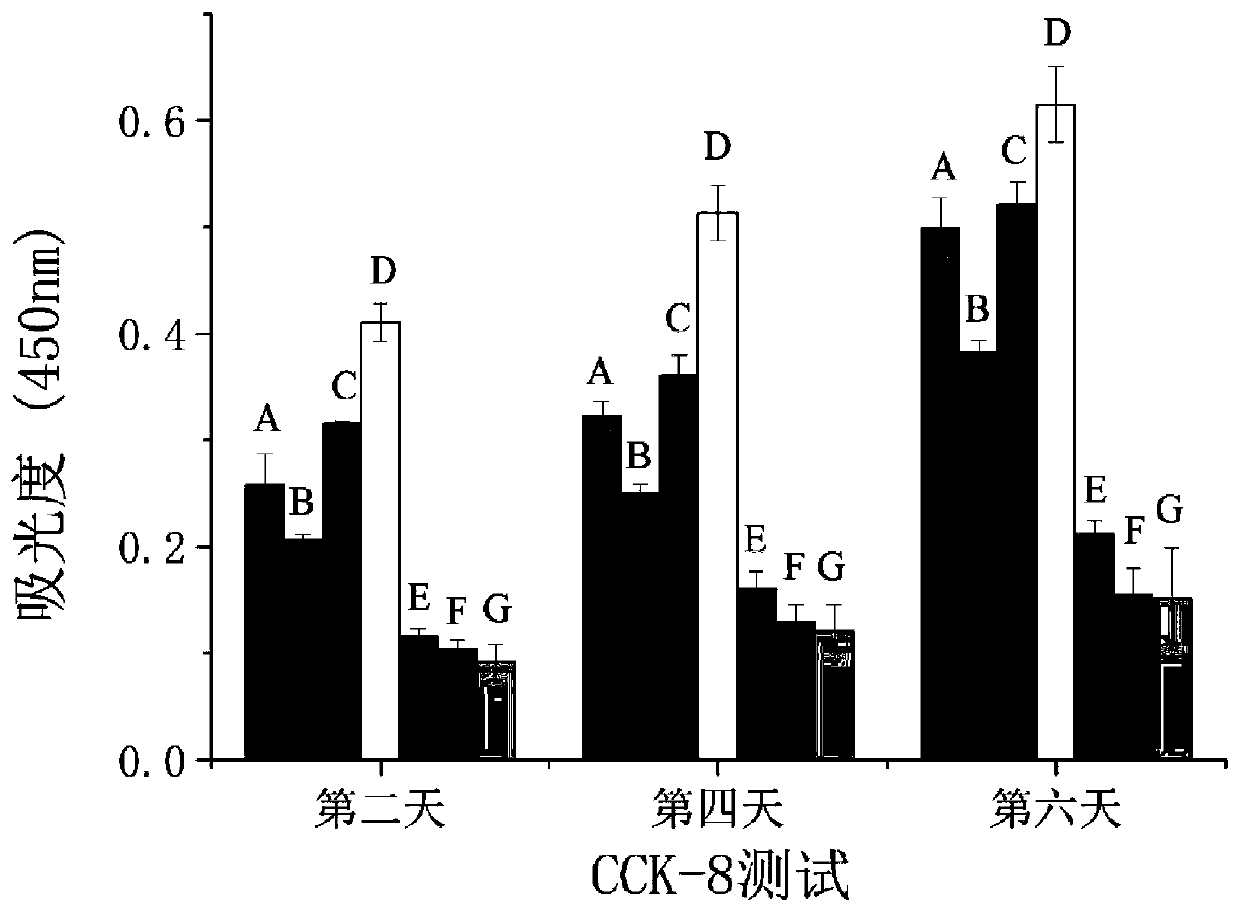

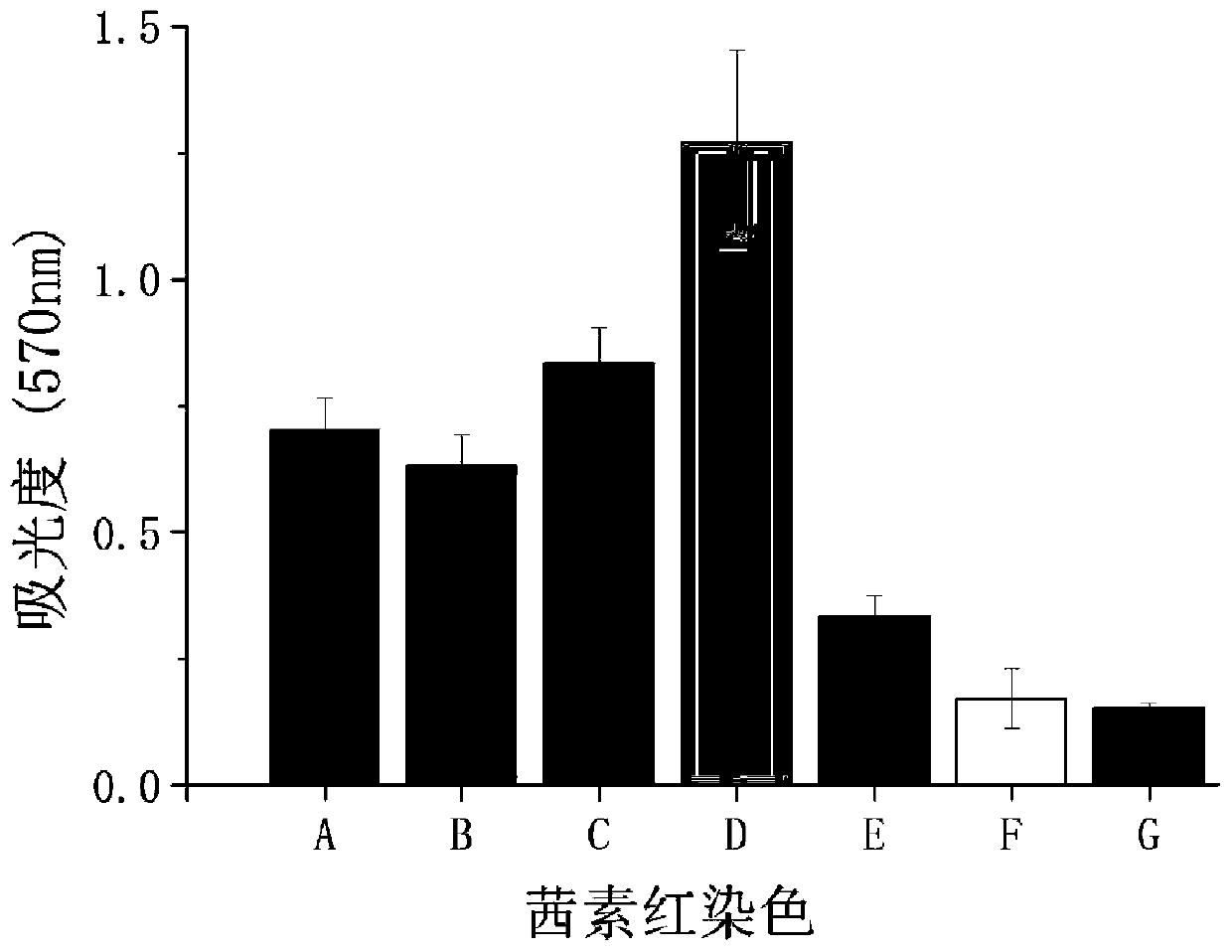

[0059] In order to evaluate the toxicity of the titanium-tantalum composite material to c...

Embodiment 3

[0064] Prepare titanium-tantalum alloy powder, wherein in the titanium-tantalum alloy powder, according to the atomic ratio, titanium: tantalum = 7:3; ball mill: ball material ratio is 4:1. 1mm < ball diameter < 5mm. The amount of powder loaded at one time = 100g. Sealed ball milling, vacuuming, vacuum degree <10Pa, filled with argon as protective gas, rotating speed 150r / min, ball milling time 18h. Then place the titanium-tantalum alloy powder in a discharge plasma sintering furnace for sintering. The sintering is completed to obtain a titanium-tantalum composite material. The sintering procedure is as follows: the heating rate is 70°C / min, the sintering temperature is 1000°C, and the sintering time is 5min; the sintering pressure 60MPa, air-cooled. The titanium-tantalum composite material was polished with 400 mesh, 600 mesh, 800 mesh, and 1200 mesh sandpaper until the surface was smooth without scratches, and then ultrasonically cleaned with ethanol, acetone, and deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com