Crystal growth device and method

A technology of crystal growth and growth furnace, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems such as restricting the preparation period of SiC crystal, volatile components or impurities, and easy destruction of SiC seed crystal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

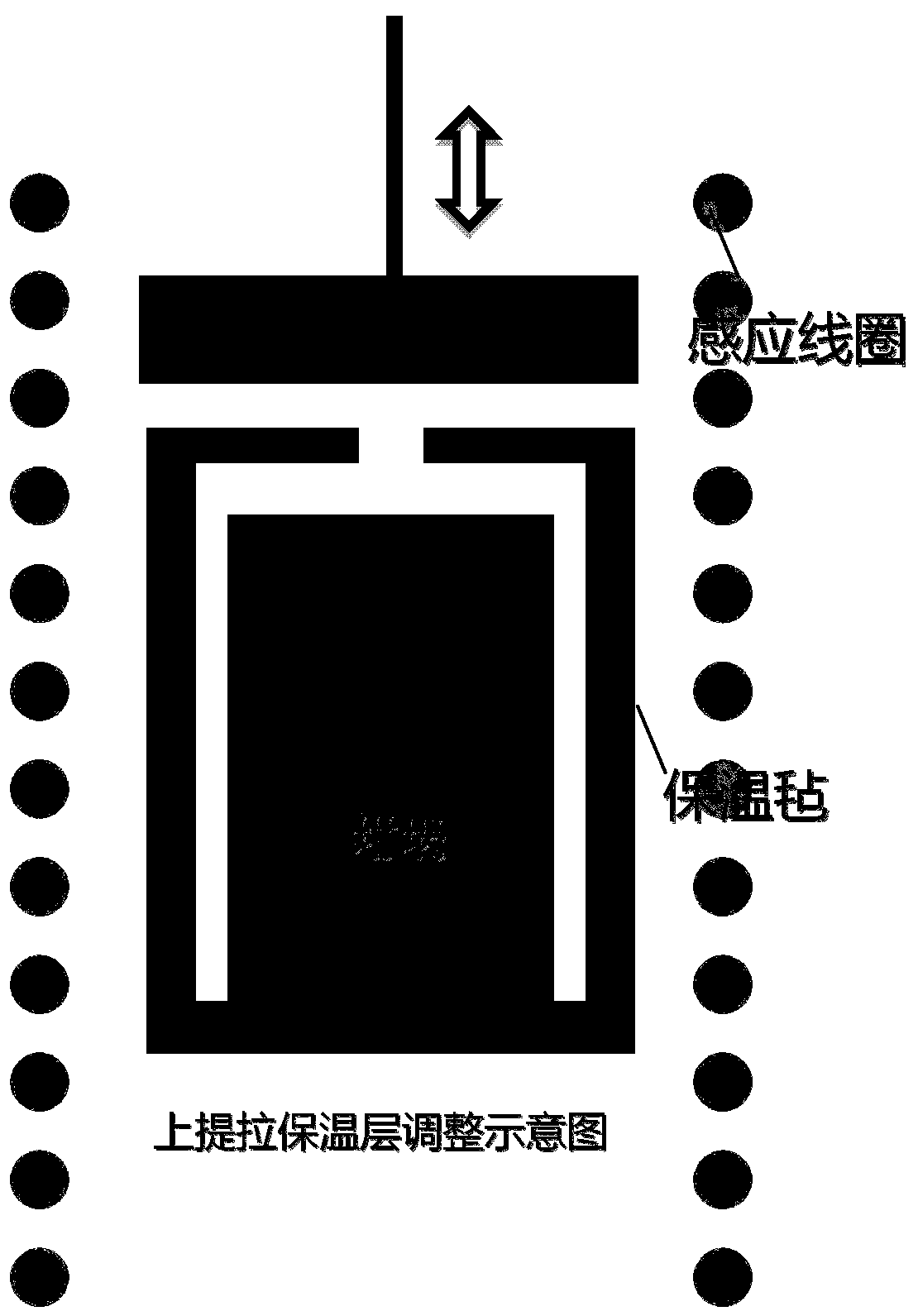

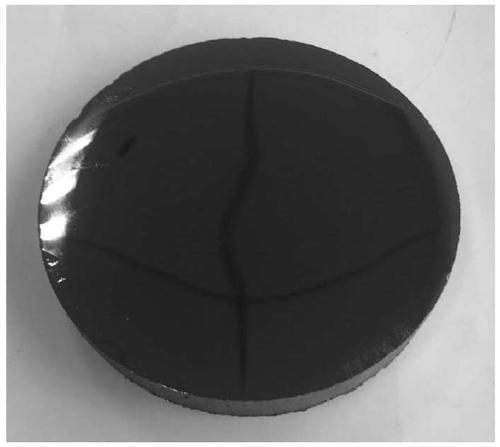

[0042] First, the graphite crucible with a diameter of 4 inches and a thickness of 400 μm seed crystal is fixed on the upper part, and the graphite crucible with silicon carbide raw material in the bottom material area is placed in the thermal insulation carbon felt (peripheral thermal insulation layer) (as a growth chamber). Place the above growth chamber in the crystal growth furnace, and pump the vacuum to 2.0×10 -4 Pa, filled with argon gas to a pressure of 10Torr, the upper insulation layer on the top of the furnace is slowly lowered until it covers the growth chamber through the lifting device on the furnace body, and the heating power is increased to 5kW to pretreat the raw materials for 3 hours, and then passed through the upper The pulling device slowly (1cm / min) pulls the insulation layer to the top of the growth furnace, and at the same time increases the heating power to 9.5kW and fills it with argon to 400Torr, keeps it for 3 hours, and then starts to lower the tem...

Embodiment 2

[0044] First, the upper part is fixed with a graphite cover with a diameter of 6 inches and a seed crystal thickness of 350 μm, and the graphite crucible with silicon carbide raw materials in the bottom material area is placed in an insulating carbon felt, and the above growth chamber is placed in a crystal growth furnace. Draw to 1.5×10 -4 Pa, filled with argon gas to a pressure of 200 Torr, slowly lower the insulation layer on the top until it covers the growth chamber through the lifting device on the furnace body, and at the same time increase the heating power to 8kW to pretreat the raw materials for 5 hours, and then pass the lifting device on the furnace body The pulling device slowly (0.5cm / min) pulls the upper insulation layer to the top of the growth furnace, and at the same time increases the heating power to 12.7kW and fills argon to 500Torr, and keeps it for 3.5 hours, and then starts to lower the temperature and pressure. First, the second The first stage took 0....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap