High-performance combustion gas turbine gas-exhaust system

A gas turbine and exhaust system technology, applied in mechanical equipment, engine components, climate sustainability, etc., can solve the problems of reducing the efficiency of the gas turbine, overheating the exhaust system shell, large displacement of the exhaust system, etc. The effect of improving safety and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

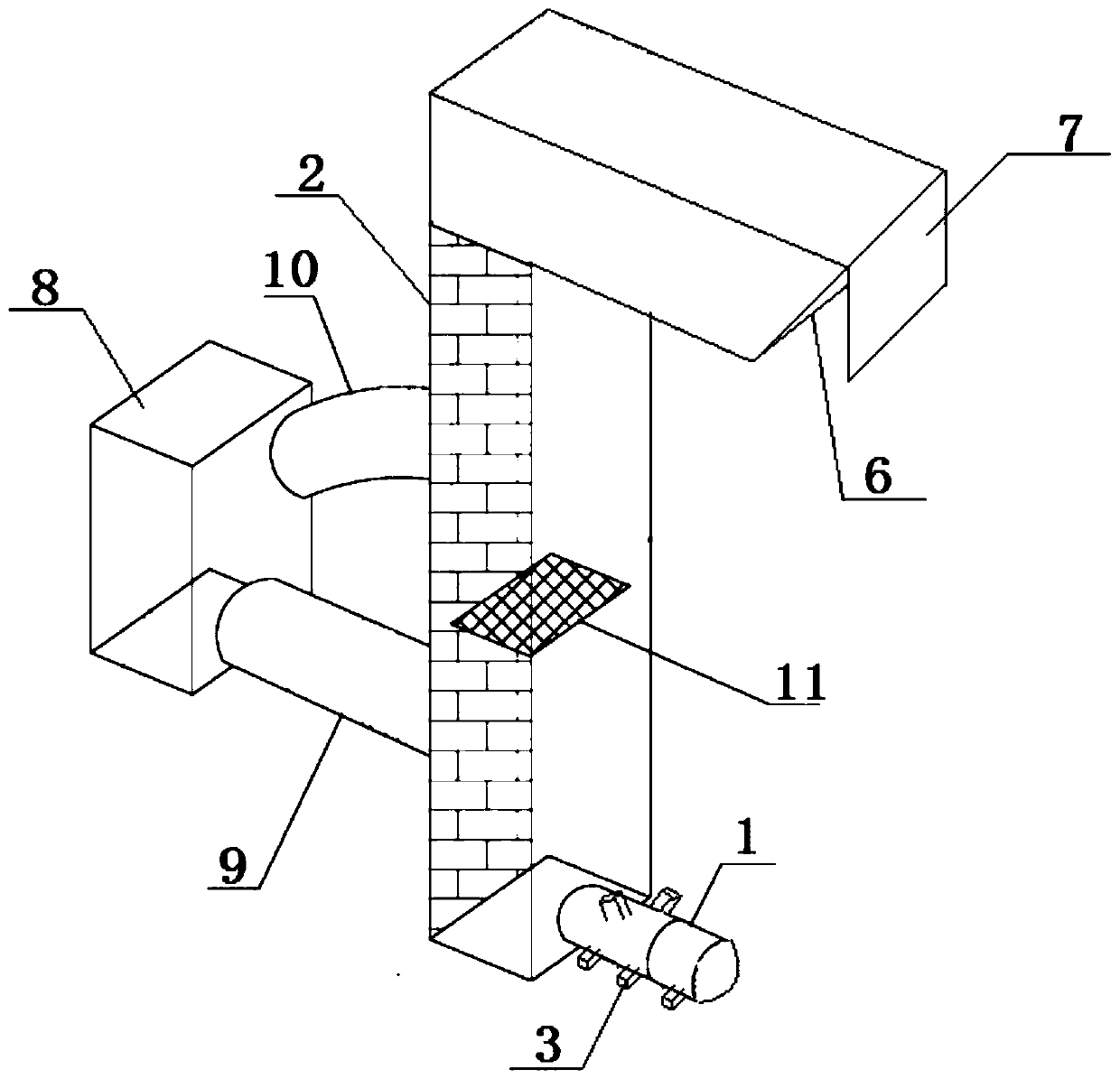

[0041] A high-performance gas turbine exhaust system provided in this embodiment has a structure such as Figure 1-2 As shown, it includes an exhaust tube 1, an exhaust tower 2 and a heat storage device. One end of the exhaust tube 1 is connected to the exhaust port of the gas turbine, and the other end is connected to the exhaust tower 2. The exhaust tower 2 is also connected to a storage heating device;

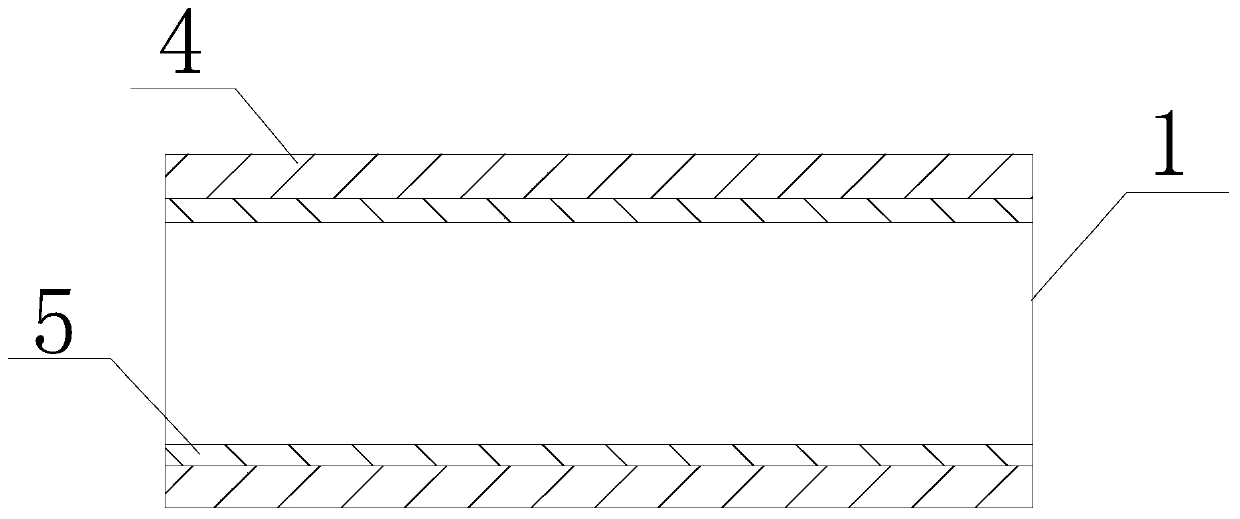

[0042]The exhaust tube 1 is a cylindrical steel plate structure with one end large and the other end small. There are several bumps 3 on the outer wall of the exhaust tube 1. The inner wall of the exhaust tube 1 is provided with a heat dissipation layer 4. The heat dissipation layer 4 is far away from the bottom of the exhaust tube 1. One side is provided with an isolation layer 5;

[0043] The top of the exhaust tower 2 extends outwards to form an exhaust tower opening 6, and the exhaust tower opening 6 is provided with a rainproof baffle 7 from top to bottom, and the rai...

Embodiment 2

[0050] This embodiment provides that the surfaces of the exhaust pipe 1 and the heat storage tank 8 in Example 1 are respectively provided with a layer of protective layer, and the protective layer is formed by coating the surface of the exhaust pipe and the heat storage tank with a protective coating. The protective coating is formed by mass parts The meter includes the following components:

[0051] Silicone modified epoxy resin: 15 parts, water-based acrylic modified polyurethane emulsion: 30 parts, talcum powder: 7 parts, phosphate: 10 parts, black silicon carbide: 10 parts, fine-grained alumina: 25 parts, dispersant : 5 parts, thickener: 3 parts, leveling agent: 4 parts, adhesion promoter: 3 parts, defoamer: 1 part, silane coupling agent: 5 parts, filler: 7 parts, compound rare earth: 0.01 share;

[0052] The composite rare earth contains the following components by weight percentage: Y: 9%, Sc: 14%, Gd: 16%, Sm: 18%, Pr: 13%, the balance is La, and the sum of the above ...

Embodiment 3

[0061] This embodiment provides that the surfaces of the exhaust pipe 1 and the heat storage tank 8 in Example 1 are respectively provided with a layer of protective layer, and the protective layer is formed by coating the surface of the exhaust pipe and the heat storage tank with a protective coating. The protective coating is formed by mass parts The meter includes the following components:

[0062] Silicone-modified epoxy resin: 17 parts, water-based acrylic modified polyurethane emulsion: 32 parts, talcum powder: 9 parts, phosphate: 18 parts, black silicon carbide: 13 parts, fine-grained alumina: 30 parts, dispersant : 8 parts, thickener: 5 parts, leveling agent: 6 parts, adhesion promoter: 4 parts, defoamer: 3 parts, silane coupling agent: 7 parts, filler: 9 parts, compound rare earth: 0.03 share;

[0063] The composite rare earth contains the following components by weight percentage: Y: 11%, Sc: 17%, Gd: 18%, Sm: 20%, Pr: 15%, the balance is La, and the sum of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com