Surface modified cyano frame material and preparation method and application thereof

A frame material and surface modification technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of sodium-ion battery electrochemical performance degradation, easy to be corroded by electrolyte, unstable structure of cyano-based frame materials, etc. , to achieve the effects of fast deintercalation, improved electrochemical performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

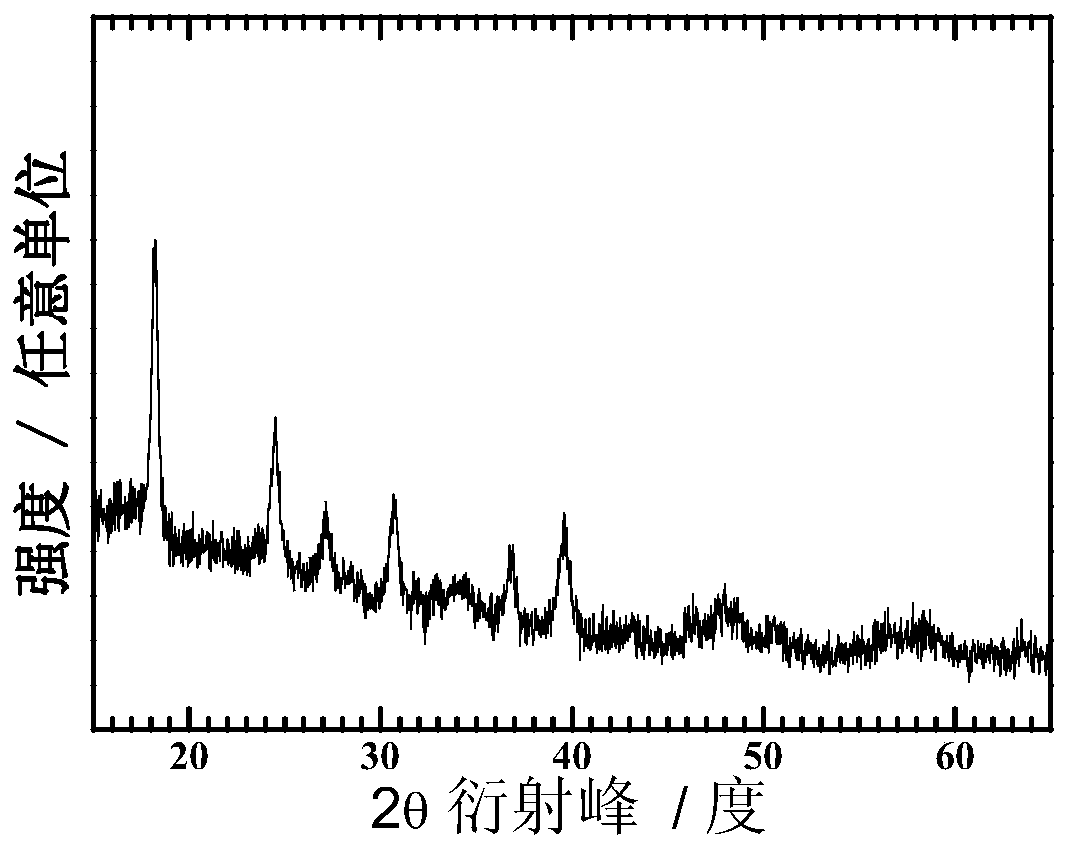

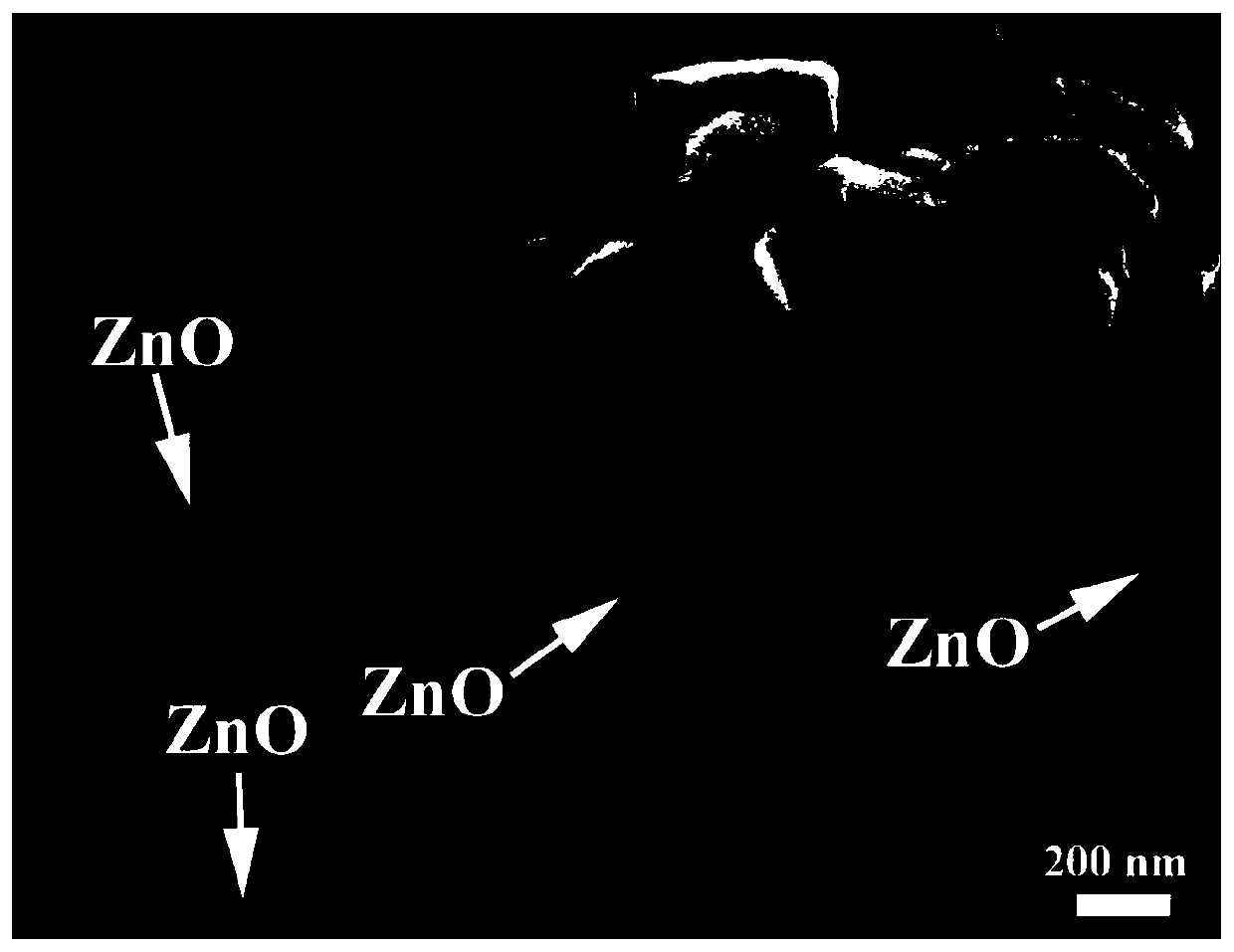

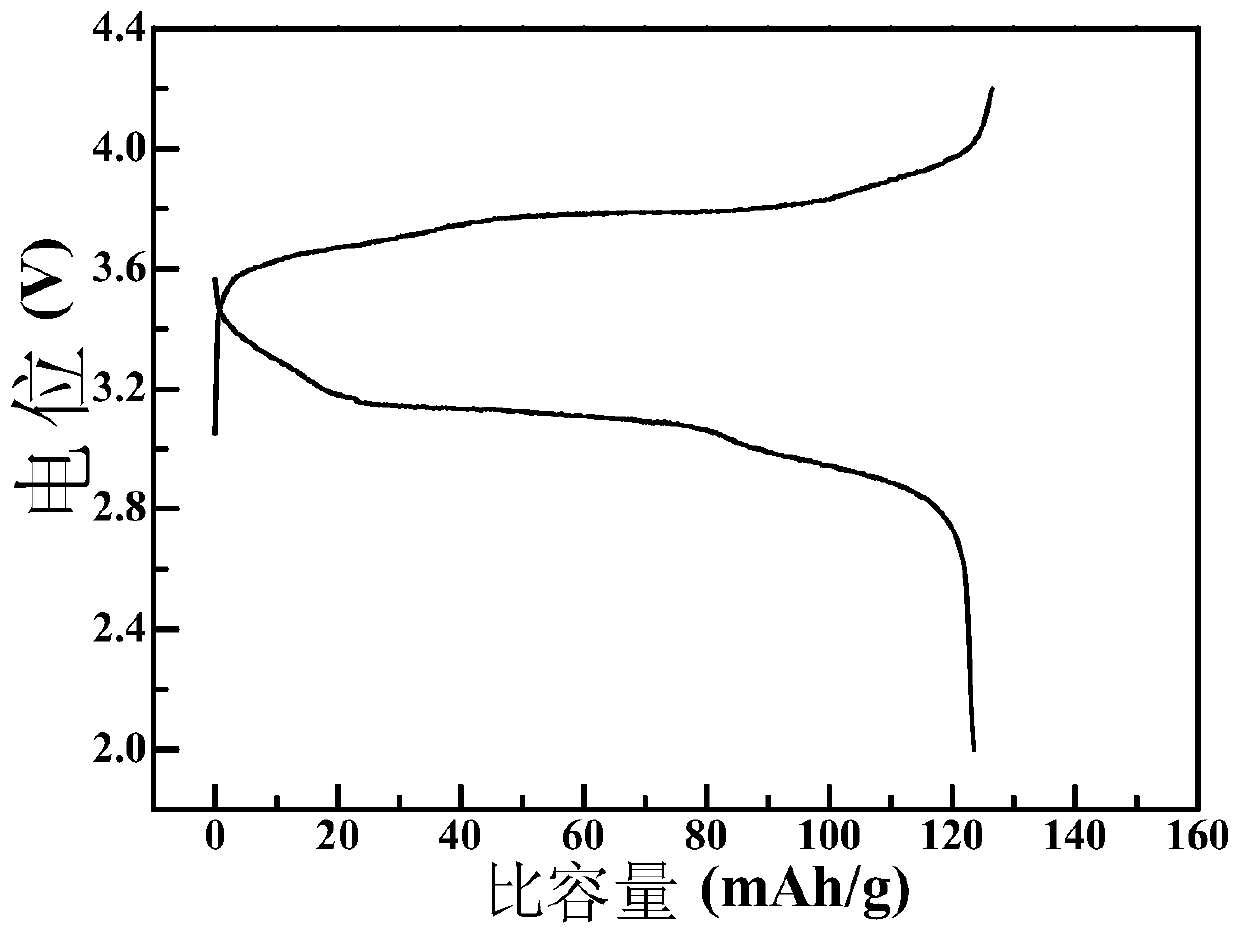

[0039] Dissolve sodium ferrocyanide decahydrate and sodium ferric pentacyanoammonium trihydrate in 1 liter of deionized water, and stir evenly to obtain concentrations of 0.495 mol / L and 0.495 mol / L in terms of ferrocyanide ion and pentacyanamide ion Solution I of 0.005mol / L; Manganous sulfate and zinc acetate are dissolved in 1 liter of deionized water to obtain 2+ Count and Zn 2+ The solutions with the concentration of 0.5mol / L and 0.05mol / L were obtained by fully stirring to obtain solution II; sodium chloride was dissolved in 1 liter of deionized water to obtain solution III with a concentration of 5mol / L; then, under constant stirring , Add solution I and solution II to solution III at the same time, and obtain a suspension through co-precipitation reaction at 85°C; then add 1.1 liters of 0.1mol / L sodium hydroxide solution to the above suspension, and then cool and wash , separation, and vacuum drying to obtain the ZnO-coated cyano-based framework material Na x Mn[Fe(CN...

Embodiment 2

[0048] Dissolve sodium ferrocyanide decahydrate and sodium ferric pentacyanoammonium trihydrate in 1 liter of deionized water, and stir evenly to obtain a concentration of 0.09mol / L and 0.09mol / L in terms of ferrocyanide ion and pentacyanamide ion Solution I of 0.01mol / L; Manganese nitrate and nickel acetate are dissolved in 1 liter of deionized water to obtain 2+ Calculated in Ni 2+ The concentration is respectively 0.1mol / L and the solution of 0.005mol / L, obtains solution II through thorough stirring; Sodium chloride is dissolved in 1 liter of deionized water, obtains the solution III that concentration is 5mol / L; Then under constant stirring , Add solution I and solution II to solution III at the same time, and obtain a suspension through co-precipitation reaction at 85°C; then add 0.105 liters of 0.1mol / L sodium hydroxide solution to the above suspension, and then cool and wash , separation, and vacuum drying to obtain the NiO-coated cyano-based framework material Na x M...

Embodiment 3

[0050] Sodium ferrocyanide decahydrate and sodium ferric pentacyanoammonium trihydrate were dissolved in 1 liter of deionized water, and stirred evenly to obtain a concentration of 0.19 mol / L and Solution I of 0.01mol / L; Manganous chloride and magnesium acetate are dissolved in 1 liter of deionized water to obtain Mn 2+ Calculated and in Mg 2+ The concentration is respectively 0.2mol / L and the solution of 0.03mol / L, obtains solution II through thorough stirring; Sodium chloride is dissolved in 1 liter of deionized water, obtains the solution III that concentration is 5mol / L; Then under constant stirring , Add solution I and solution II to solution III at the same time, and obtain a suspension through co-precipitation reaction at 85°C; then add 0.69 liters of 0.1mol / L sodium hydroxide solution to the above suspension, and then cool and wash , separation, and vacuum drying to obtain the MgO-coated cyano-based framework material Na x Mn[Fe(CN) 6 ] 0.95 [Fe(CN) 5 NH 3 ] 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com