Perovskite quantum dot and low-dimensional oxide composite luminescent material, preparation method and application thereof

A technology of perovskite materials and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of poor stability, difficult synthesis, and few literature reports, and achieve high purity of luminous color and application Effects of broad prospects, fluorescence lifetime, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

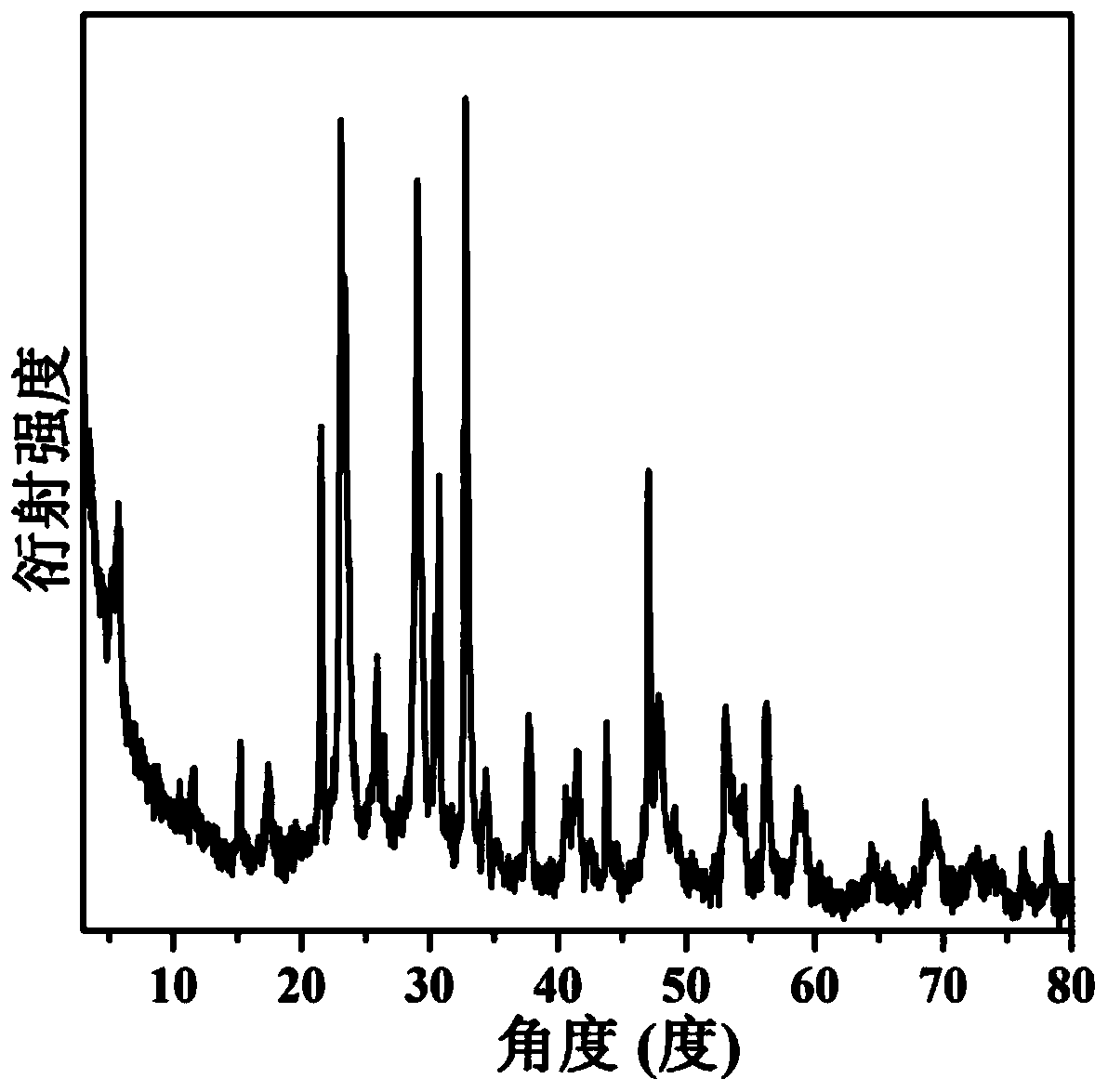

[0045] (1) Accurately weigh 0.2g bulk layered perovskite material (CsCa 2 Ta 3 o 10 ), added to 5.0ml, 1.0mol / L hydrochloric acid, stirred at a constant temperature of 25°C for 60 hours (the stirring speed was 700r / min), evaporated to dryness at 90°C to evaporate the remaining hydrochloric acid solution, and obtained a layered material protonated by hydrochloric acid;

[0046] (2) Add 8.0ml of oleylamine and 2.0ml of ethylamine to the protonated layered material of hydrochloric acid obtained in step (1), and stir at a constant temperature of 25°C for 24h (the stirring speed is 700r / min). layered materials;

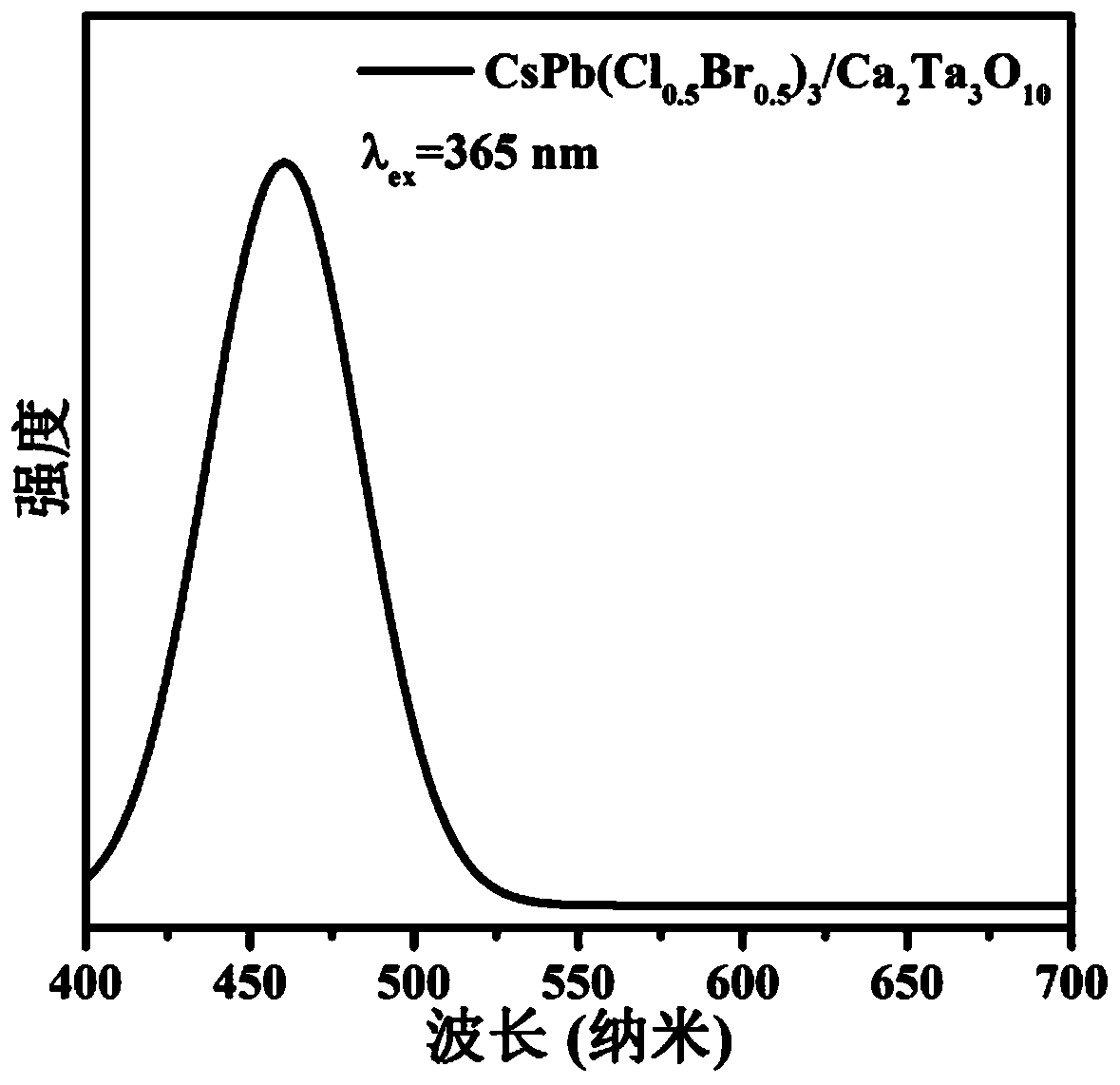

[0047] (3) Add 5ml of octadecene (ODE), 1ml of oleic acid (OA), 1ml of oleylamine (OAm), lead chloride (PbCl 2 ) 0.046g and lead bromide (PbBr 2 ) 0.06g was mixed in a 50ml three-neck flask, and 1.0ml trioctylphosphine was added, vacuumized at 80°C for 30min, N 2 Under the atmosphere, stir at 150°C (the rotating speed of stirring is 600r / min) until the lead chloride a...

Embodiment 2

[0051] (1) Accurately weigh 0.2g bulk layered perovskite material (CsCa 2 Ta 3 o 10 ), was added to 10.0ml oleic acid, stirred at 150°C for 10h (rotating speed of stirring was 100r / min), to obtain a protonated layered material of oleic acid;

[0052] (2) Add 5.0ml of oleylamine and 5.0ml of octylamine to the protonated layered material of oleic acid obtained in step (1), and stir at a constant temperature of 50°C for 72h (stirring speed is 100r / min). layered materials;

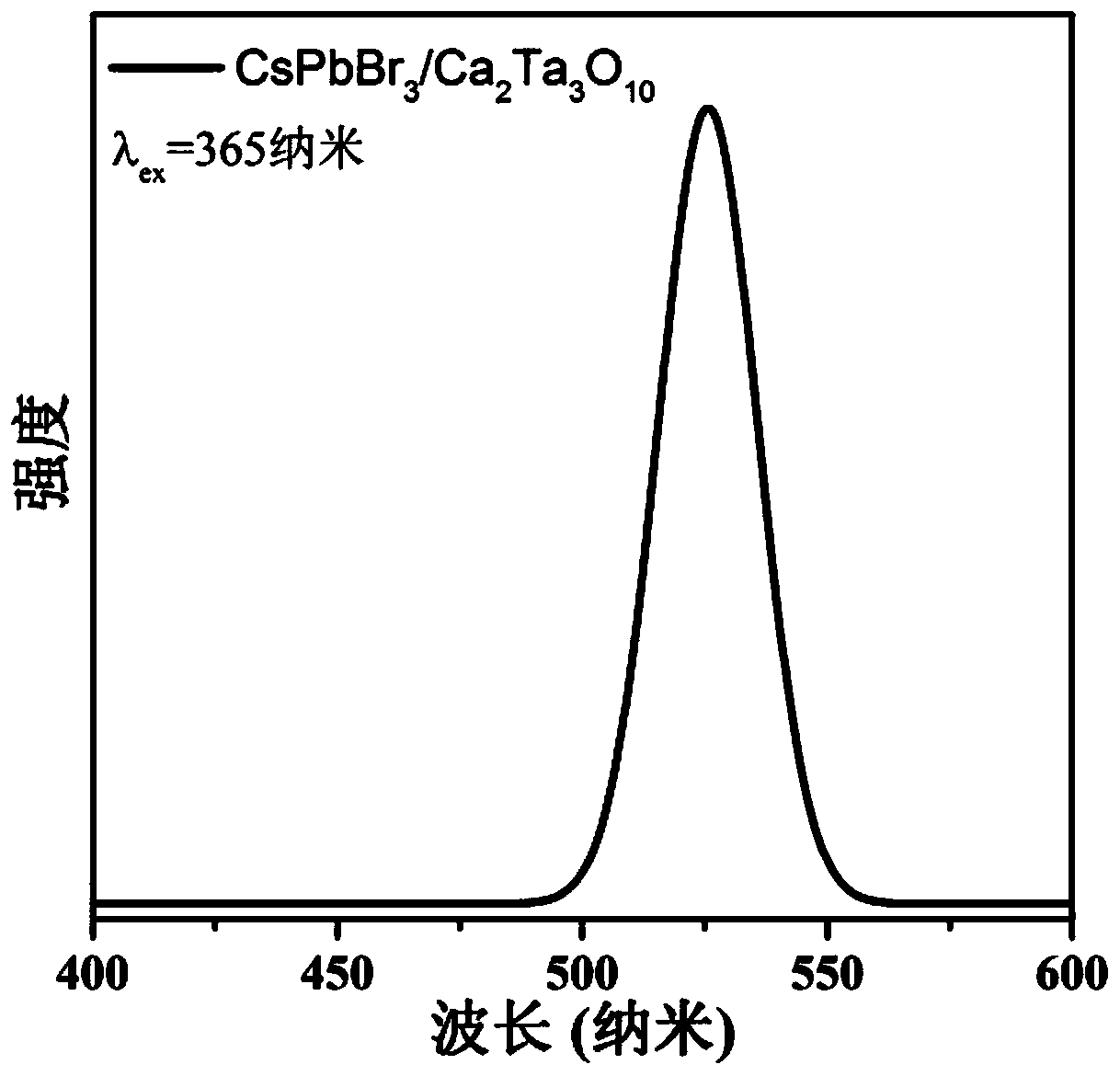

[0053] (3) 5ml of octadecene (ODE), 1ml of oleic acid (OA), 1ml of oleylamine (OAm), lead bromide (PbBr) 2 )0.12g was mixed in a 50ml three-necked bottle, and vacuumized at 80°C for 10min, N 2 Stir at 120°C under the atmosphere (the stirring speed is 100r / min) until the lead bromide is completely dissolved to obtain a lead solution of lead bromide;

[0054] (4) Add 5ml of octadecene (ODE) to the layered material peeled off in step (2) and mix it in a 50ml three-necked bottle, vacuumize at 80°C for 10min, ...

Embodiment 3

[0057] (1) Accurately weigh 0.2g bulk layered perovskite material (CsCa 2 Ta 3 o 10 ), added to 5.0ml, 3.0mol / L nitric acid, stirred at 25°C for 3 hours (the stirring speed was 1000r / min), evaporated to dryness at 70°C to evaporate the remaining nitric acid solution, and obtained a layered material protonated with nitric acid;

[0058] (2) Add 10.0 ml of oleylamine to the protonated layered material of nitric acid obtained in step (1), stir at a constant temperature of 30°C for 168 hours (the stirring speed is 1000r / min), and peel off the protonated layered material;

[0059] (3) 5ml of octadecene (ODE), 1ml of oleic acid (OA), 1ml of oleylamine (OAm), lead bromide (PbBr) 2 )0.12g was mixed in a 50ml three-neck bottle, and vacuumized at 100°C for 15min, N 2 Stir at 130°C under the atmosphere (the stirring speed is 500r / min) until the lead bromide is completely dissolved to obtain a lead solution of lead bromide;

[0060] (4) Add 5ml of octadecene (ODE) to the layered mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com