Adjustable photochromic phosphor powder, phosphor thin film, preparation method and application thereof

A phosphor and light color technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of cadmium doping difficulties, cadmium ion radius, stability and growth temperature differences, etc., and achieve chemical and optical properties. Stable, high luminous efficiency, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Add 0.001mol CdCl 2 Grinding with 0.02mol ZnS at room temperature for 15-30 minutes to obtain the precursor;

[0039] 2) Put the above precursor into a 50ml crucible, seal it with a lid; put it into a muffle furnace and sinter at 700°C for 3 hours;

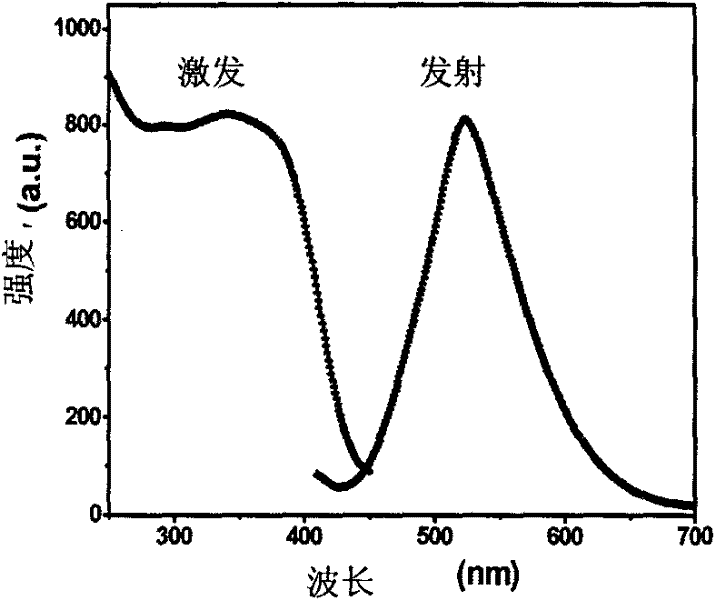

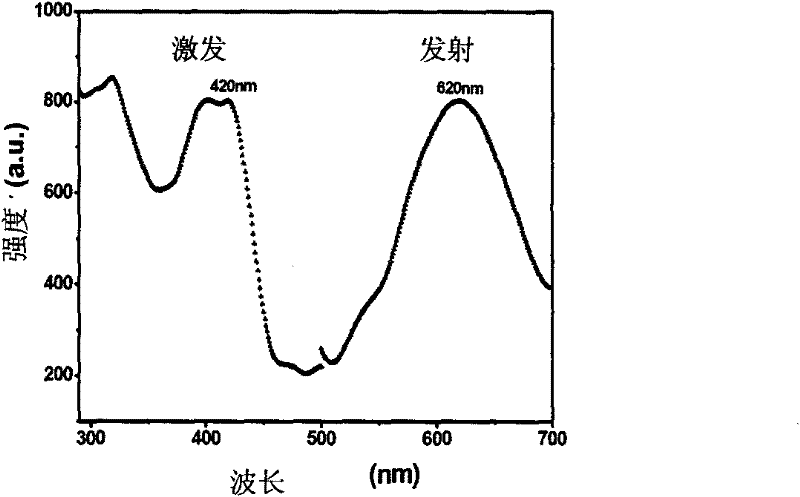

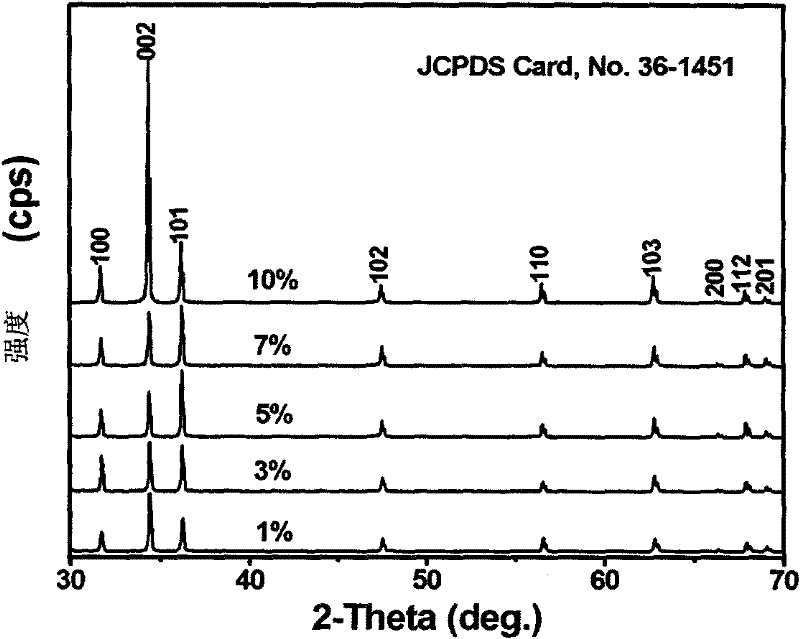

[0040] 3) After cooling, take out the sintered material and grind it for 5 to 10 minutes, wash it with deionized water and alcohol, and dry it to get the light color tunable phosphor. The general formula of its composition is ZnCd as determined by energy dispersive X-ray spectroscopy. 0.05 o 1.05 :S y , where y=0.0001~0.01. Its particle size ranges from 100nm to 2um, as shown in the SEM image Figure 4 shown.

[0041] 4) Take 0.5 g of the tunable phosphor powder obtained above, mix it with 200 ml of 0.15 g / L sodium benzenesulfonate aqueous solution, perform ultrasonic dispersion, and stir in a water bath at 65°C for 60 minutes to obtain the precursor;

[0042] 5) Add 6 g of MMA monomer and 0.05 g of potassium persu...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is: ZnS and CdCl 2 The mol ratio is 1: 0.01, and all the other contents are described in Example 1, thereby obtaining the target product, its composition general formula is ZnCd measured by energy dispersive X-ray spectrum 0.01 o 1.01 :S y , where y=0.0001~0.01. The XRD analysis results and the fluorescence spectrum analysis results of the obtained sample are the same as those described in Example 1.

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is: ZnS and CdCl 2 The mol ratio is 1: 0.03, and all the other contents are described in Example 1, thereby obtaining the target product, its composition general formula is ZnCd measured by energy dispersive X-ray spectrum 0.03 o 1.03 :S y , where y=0.0001~0.01. The XRD analysis results and the fluorescence spectrum analysis results of the obtained sample are the same as those described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com