A kind of organic carbon nanosphere lubricating oil additive and its preparation method and application

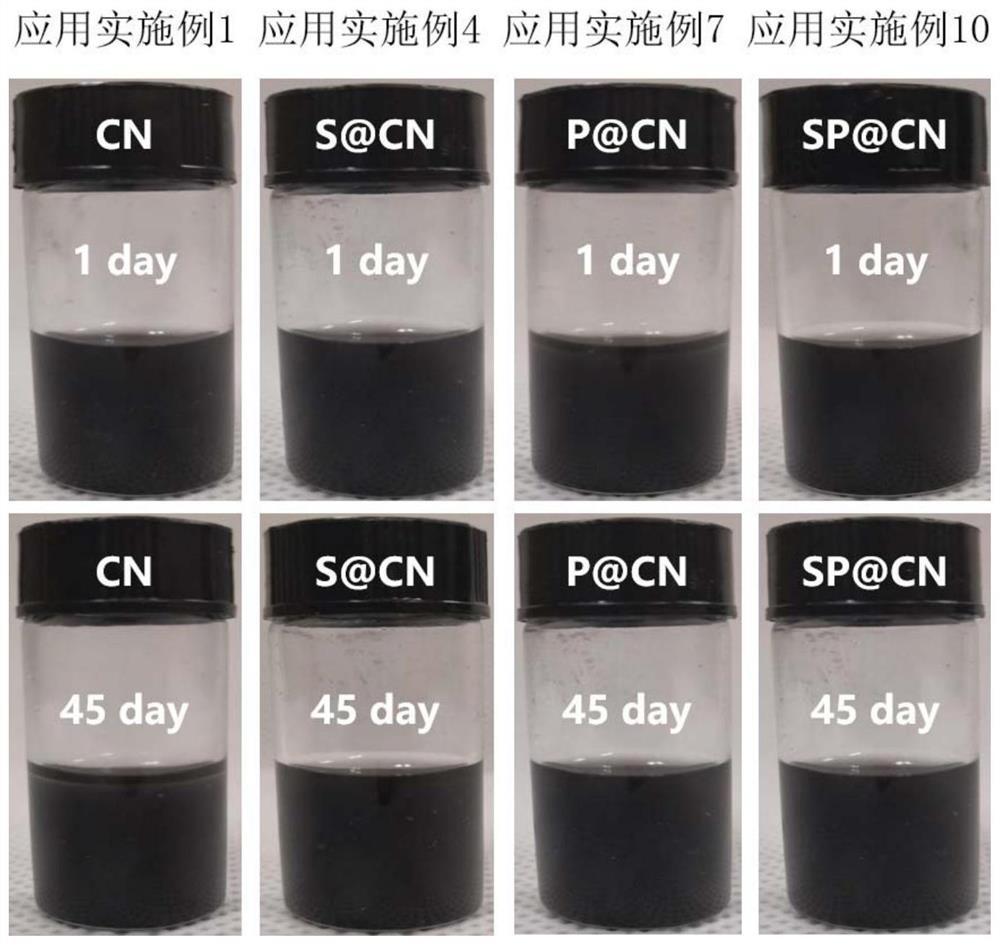

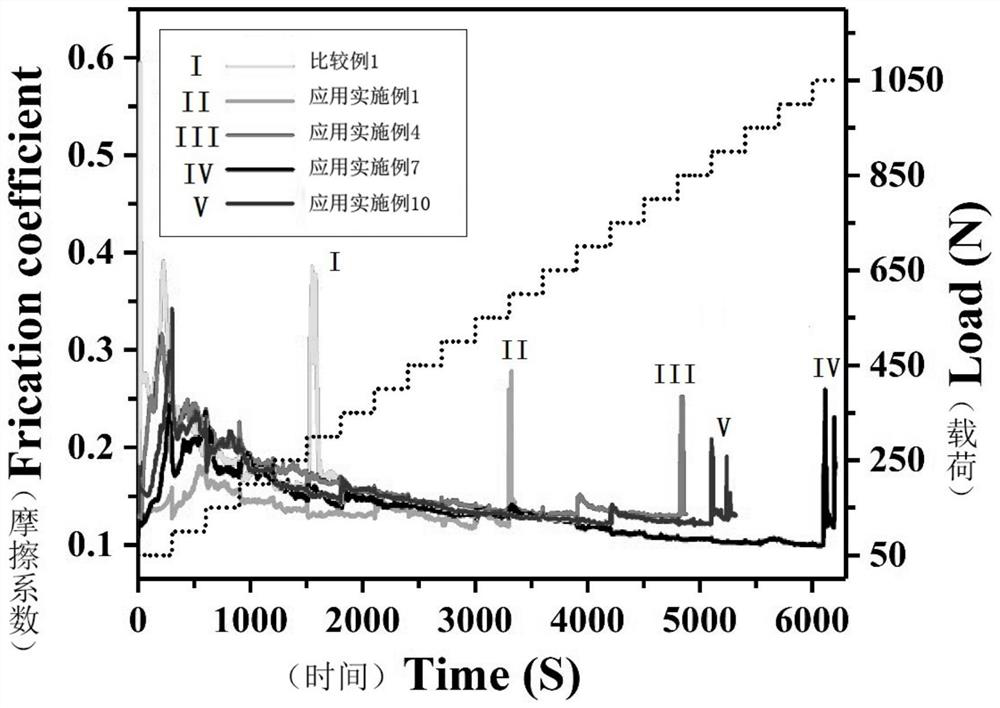

A lubricating oil additive, organic carbon technology, applied in the directions of additives, nanotechnology, nanotechnology, etc., can solve the problems of poor dispersion stability of nanoparticles, reduced nanoparticle stability, complex process, etc. The effect of increasing the frictional contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

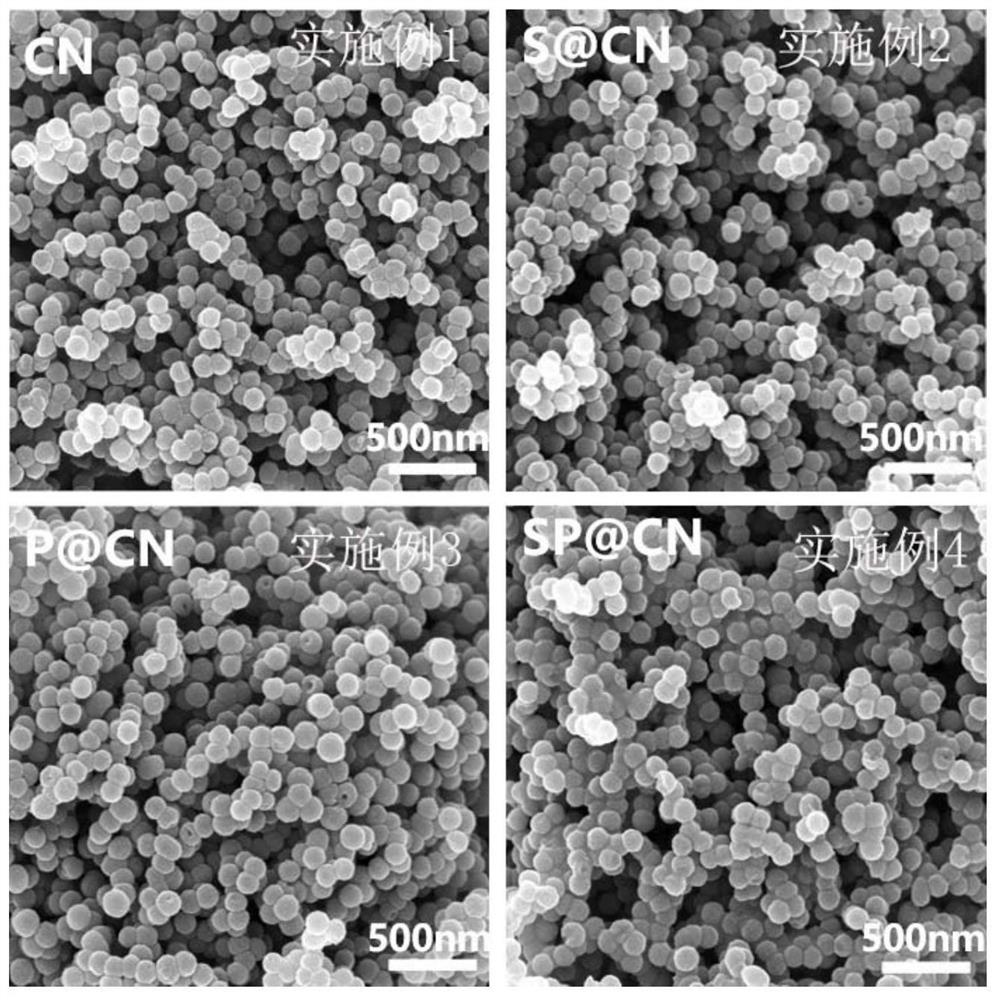

[0038] An organic carbon nanosphere lubricating oil additive, comprising an organic carbon nanosphere and a doping element doped on the organic carbon nanosphere by carbonization, the doping element is N element, and the mass percentage of the doping element in the additive is 18.9%.

[0039] Concrete preparation method comprises the following steps:

[0040] S1. Preparation of organic carbon precursor:

[0041] With 0.49mol aniline and 0.38mol pyrrole as reaction monomer, once add the mixed solution that 60ml is made up of deionized water and acetonitrile, stir evenly, wherein, the volume ratio of deionized water and acetonitrile in the mixed solution is 2:1;

[0042] After stirring evenly, the solution was colorless and transparent, and then reacted for 10 hours at 90°C with a stirring speed of 1000rpm. After the reaction was completed, a solid product was precipitated. After filtering and washing the precipitated solid product, it was heated at 80°C for 10 hours drying to...

Embodiment 2

[0046] An organic carbon nanosphere lubricating oil additive, including organic carbon nanospheres and doping elements doped on the organic carbon nanospheres by carbonization, the doping elements are N and S elements, and the mass of the doping elements in the additive The percentage is 26.2%.

[0047] Concrete preparation method comprises the following steps:

[0048] S1, the preparation of organic carbon precursor: the preparation method is exactly the same as that of Example 1;

[0049] S2, the preparation of additive:

[0050] Take 200mg of organic carbon precursor and place it in the center of the tube furnace, put 3g of thiourea at the air inlet of the tube furnace at 180°C to 200°C, and inject N 2 , the flow rate is 80ml / min, after the temperature in the tube furnace is raised from room temperature to 500°C, it is kept for 3h, and the heating rate is 5°C / min, and the organic carbon nanosphere additive (S@CN) containing the dopant source is obtained; Among them, the ...

Embodiment 3

[0052] An organic carbon nanosphere lubricating oil additive, including organic carbon nanospheres and doping elements doped on the organic carbon nanospheres by carbonization, the doping elements are N and P elements, and the mass of the doping elements in the additive The percentage is 23.3%.

[0053] Concrete preparation method comprises the following steps:

[0054] S1, the preparation of organic carbon precursor: the preparation method is exactly the same as that of Example 1;

[0055] S2, the preparation of additive:

[0056] Take 200mg of organic carbon precursor, place it in the center of the tube furnace, put 3g of ammonium hypophosphite at the air inlet of the tube furnace at 180°C to 200°C, and feed N 2 , the flow rate is 80ml / min, after the temperature in the tube furnace is raised from room temperature to 500°C, it is kept for 3h, and the heating rate is 5°C / min, and the organic carbon nanosphere additive (P@CN) containing the doping source is obtained; Among t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com