Ultrahigh-flowability dynamic vulcanized thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and dynamic vulcanization technology, applied in the field of thermoplastic elastomer materials and their preparation, can solve the problems of limited oil absorption capacity of EPDM rubber, lower temperature resistance of finished products, lower system viscosity, etc., and achieve excellent physical and mechanical properties, Good heat resistance and improved modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

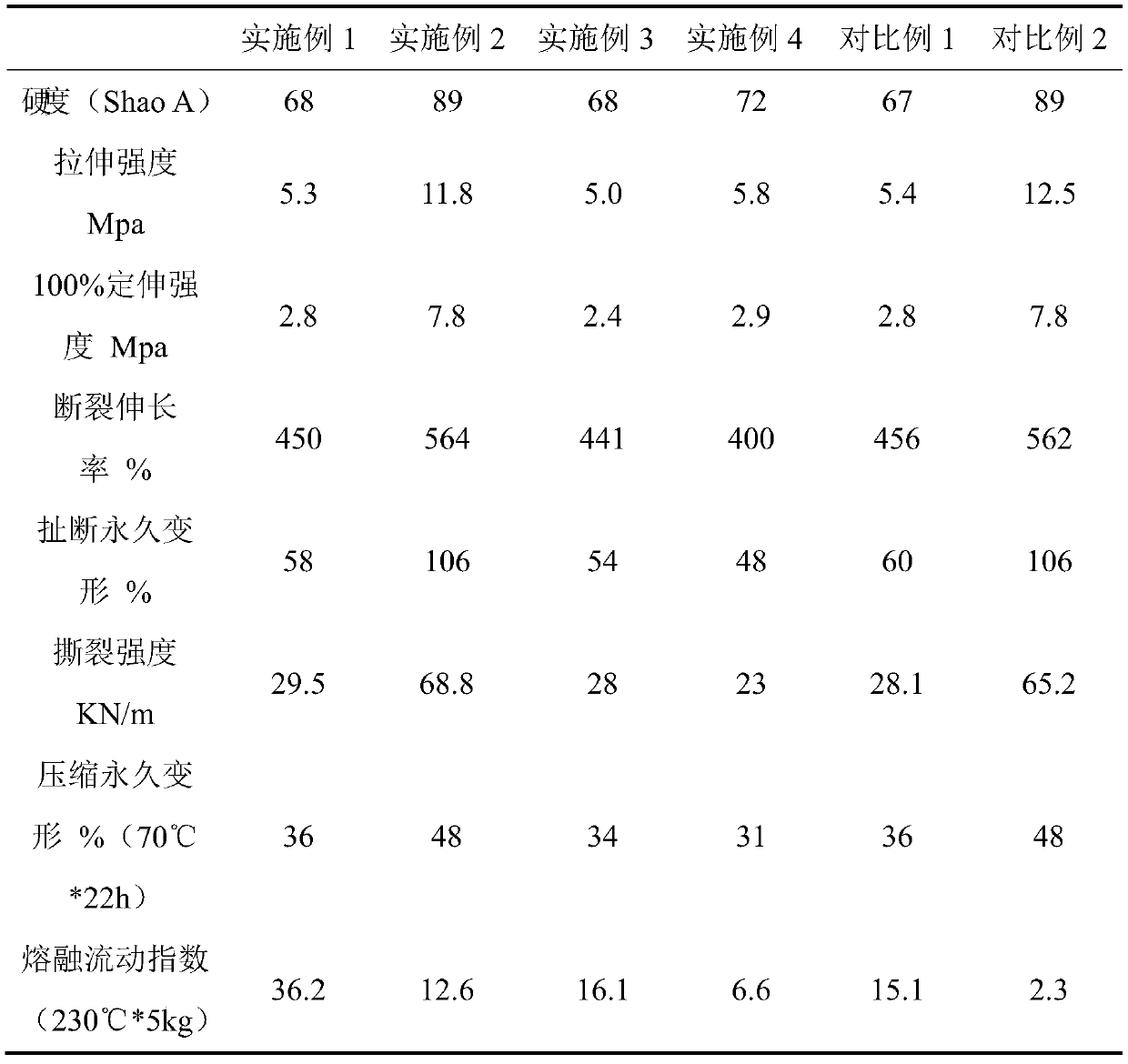

Examples

Embodiment 1

[0036] 1) Weigh 1Kg EPDM rubber (Mooney viscosity 60, ethylene content 66%, the third monomer ethylidene norbornene content 5%), 0.5Kg homopolypropylene (melt index is 10g / 10min) , 0.2Kg ultra-high fluidity atactic polypropylene (melt index: 100 g / 10min (230°C.2.16kg)). Add it into the high-speed stirring pot, then add 2g of antioxidant, 15g of lubricant and 0.3Kg of superfine calcium carbonate, turn on the high-speed stirring pot for homogenization and mixing for 1min (set the speed at 500r / min), pass the resulting mixture through the twin-screw After processing by the extruder, intermediates are obtained;

[0037] 2) Add 2g of cross-linking agent p-bis-tert-butyl peroxide cumene (BIPB), 10g of auxiliary cross-linking agent triallyl isocyanurate (TAIC) in the intermediate obtained in step (1), 10g light stabilizer and 15g lubricant are added in the high-speed mixer, after stirring at a high speed for 1min (the setting speed is 500r / min), the resulting mixture is processed by...

Embodiment 2

[0039] 1) Weigh 1Kg of EPDM rubber (Mooney viscosity 60, ethylene content 66%, third monomer ethylidene norbornene content 5%), 1Kg homopolypropylene (melt index is 10 g / 10min) , 0.5Kg ultra-high fluidity atactic polypropylene (melt index is 100g / 10min (230 ° C. 2.16kg)) into the high-speed stirring pot, then add 2g of antioxidant, 15g of lubricant and 0.3Kg of Ultrafine calcium carbonate, open the high-speed stirring pot homogenization and mix 1min (setting rotating speed is 500r / min), after gained mixture is processed by twin-screw extruder, obtain intermediate;

[0040] 2) Add 2g of cross-linking agent p-bis-tert-butyl peroxide cumene (BIPB), 10g of auxiliary cross-linking agent triallyl isocyanurate (TAIC) in the intermediate obtained in step (1), 10g light stabilizer and 15g lubricant are added in the high-speed mixer, after stirring at high speed for 1min (the setting speed is 500r / min), the resulting mixture is processed by a twin-screw extruder, and 150g paraffin oil i...

Embodiment 3

[0042] 1) Weigh 1Kg EPDM rubber (Mooney viscosity 60, ethylene content 66%, the third monomer ethylidene norbornene content 5%), 0.5Kg homopolypropylene (melt index is 10g / 10min) , 0.2Kg ordinary random polypropylene (melt index is 15g / 10min (230 ℃.2.16kg)) joins in the high-speed stirring pot, then adds the superfine calcium carbonate of 2g antioxidant, 15g lubricant and 0.3Kg, Turn on the high-speed stirring pot for homogenization and mixing for 1min (the setting speed is 500r / min), and after the resulting mixture is processed by a twin-screw extruder, an intermediate is obtained;

[0043] 2) Add 2g of cross-linking agent p-bis-tert-butyl peroxide cumene (BIPB), 10g of auxiliary cross-linking agent triallyl isocyanurate (TAIC) in the intermediate obtained in step (1), 10g light stabilizer and 15g lubricant are added in the high-speed mixer, after stirring at a high speed for 1min (the setting speed is 500r / min), the resulting mixture is processed by a twin-screw extruder, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com