Method for preparation of bio-oil by microwave thermal cracking of biomass

A biomass and bio-oil technology, which is used in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oil, can solve the problems of low bio-oil yield, harsh process conditions, and high production costs, and reduce pollutant emissions. , High degree of cracking, the effect of preventing secondary cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

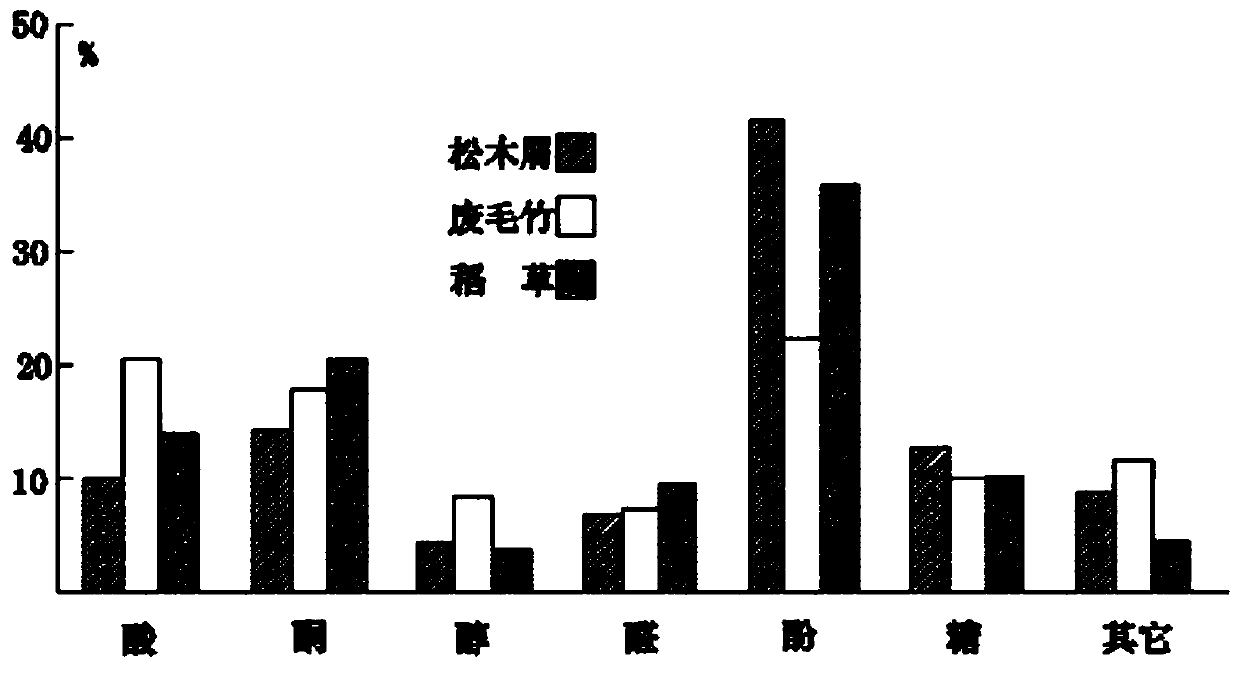

Embodiment 1

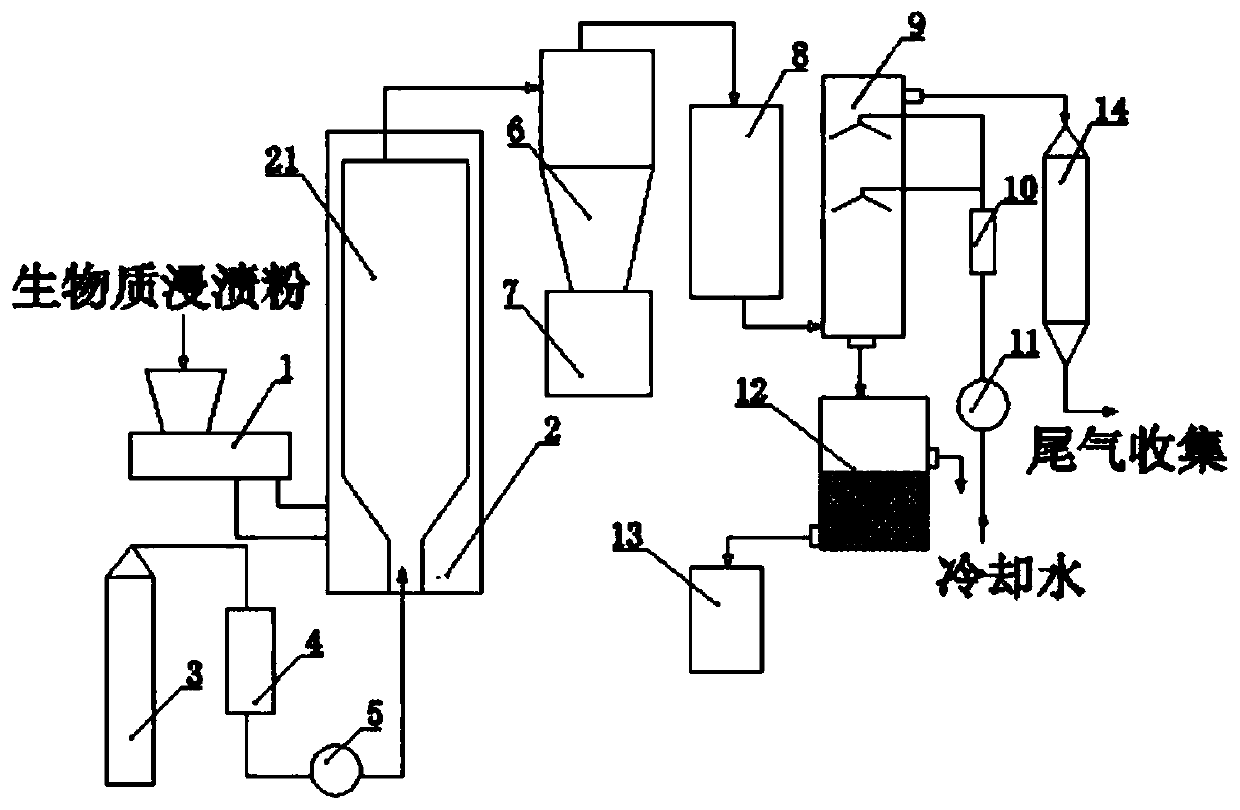

[0023] A method for preparing bio-oil by microwave pyrolysis of biomass, the method comprises the following steps:

[0024] (1). Pretreatment of straw biomass materials:

[0025] 1). Cut 500 grams of rice straw into small pieces of 4cm to 6cm, clean the impurities and dirt, and dry in the air.

[0026] 2). Crushing small pieces of straw into powder particles;

[0027] 3). The rice straw powder particles are ball-milled, and the ball-milled rice straw material is passed through a 140-mesh sieve or a 170-mesh sieve; the sieved straw material is dried at 60-70° C. in a drying oven to obtain a pretreated rice straw powder;

[0028] 4). Dissolve a certain amount of ionic liquid in distilled water, add pretreated rice straw powder into the solution, stir evenly, then add catalyst, soak for 3 hours, and dry the soaked rice straw powder Carry out 60~70 ℃ drying in box to constant weight, get rice straw impregnation powder;

[0029] (2). Preparation of bio-oil:

[0030] 1). The nit...

Embodiment 2

[0035] A method for preparing bio-oil by microwave pyrolysis of biomass, the method comprises the following steps:

[0036] (1). Bamboo slice biomass material pretreatment:

[0037] 1). Cut 700 grams of waste moso bamboo slices into 4cm-6cm sections, clean the impurities and dirt, and dry them in the air.

[0038] 2). Crushing waste bamboo chips into powder particles;

[0039] 3). Ball mill the powder of moso bamboo flakes, pass the milled peanut shell material through a 140-mesh sieve or a 170-mesh sieve; dry the sieved moso bamboo flakes material at 60-70°C in a drying oven to obtain pretreated moso bamboo flake powder;

[0040] 4). Dissolve a certain amount of ionic liquid in distilled water, add the pretreated moso bamboo flakes powder into the solution, stir evenly, then add catalyst, soak for 3 hours, and soak the impregnated moso bamboo flakes powder Carry out 60~70 ℃ drying in drying oven to constant weight, obtain Moso bamboo slice impregnation powder;

[0041] (2...

Embodiment 3

[0047] A method for preparing bio-oil by microwave pyrolysis of biomass, the method comprises the following steps:

[0048] (1). Pretreatment of pine sawdust biomass material:

[0049] 1). Cut 600 grams of pine sawdust into small pieces of 4cm to 6cm, clean the impurities and dirt, and dry in the air.

[0050] 2). Crushing small pieces of pine sawdust into powder particles;

[0051]3). The pine sawdust powder particles are ball milled, and the pine sawdust material after ball milling is passed through a 140-mesh sieve or a 170-mesh sieve; the sieved pine sawdust material is dried at 60-70°C in a drying oven to obtain pretreated pine wood crumb powder;

[0052] 4). Dissolve a certain amount of ionic liquid in distilled water, add pretreated pine sawdust powder into the solution, stir evenly, then add catalyst, soak for 3 hours, and soak the impregnated pine sawdust powder Drying at 60-70°C in a drying oven to constant weight to obtain pine sawdust impregnation powder;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com