Preparation method of biologically active chronic wound auxiliary material and application thereof

A technology of biological activity and surface excipients, applied in medical science, bandages, etc., can solve the problems of multifunctional hydrogel dressings that have not been reported yet, and achieve chemical synthesis methods that are environmentally friendly, biocompatible, cheap and easy to obtain, and biocompatible good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

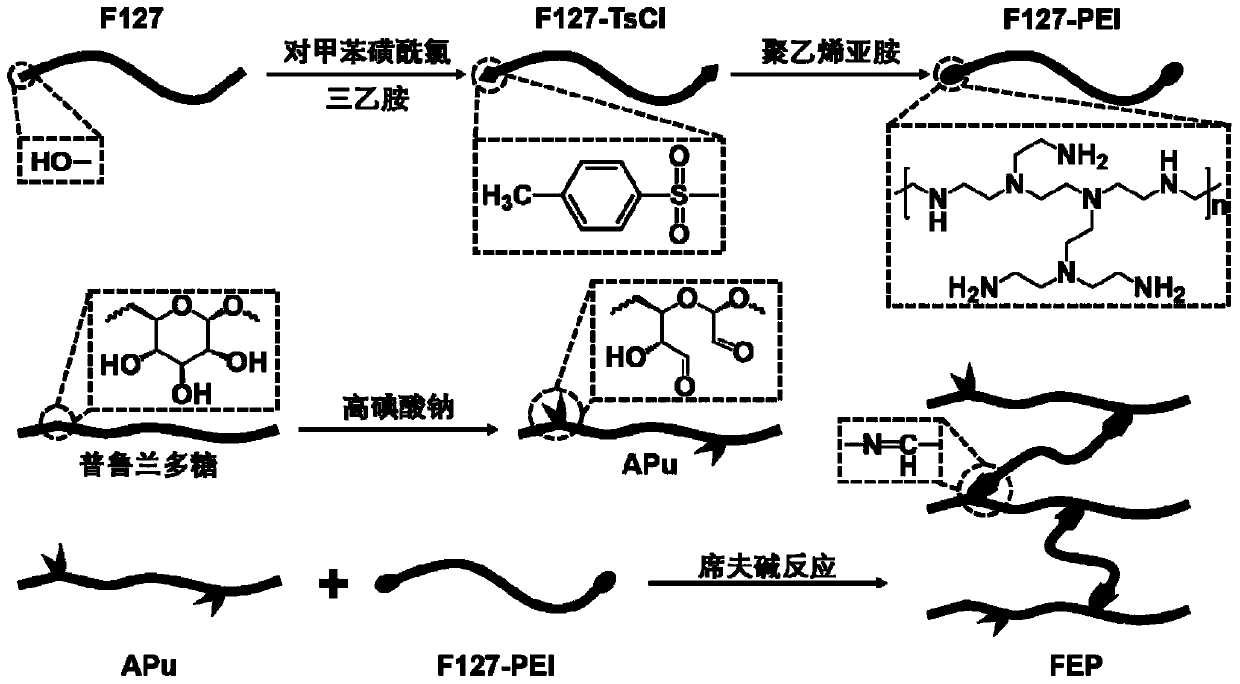

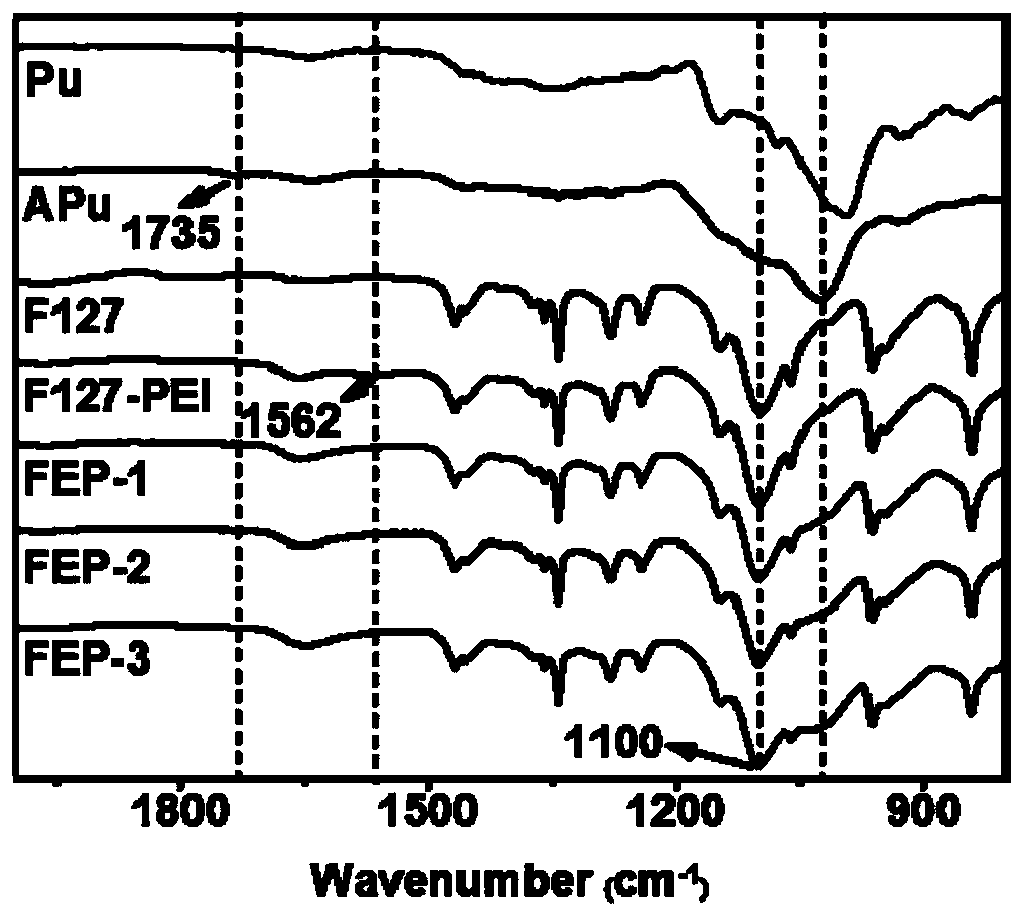

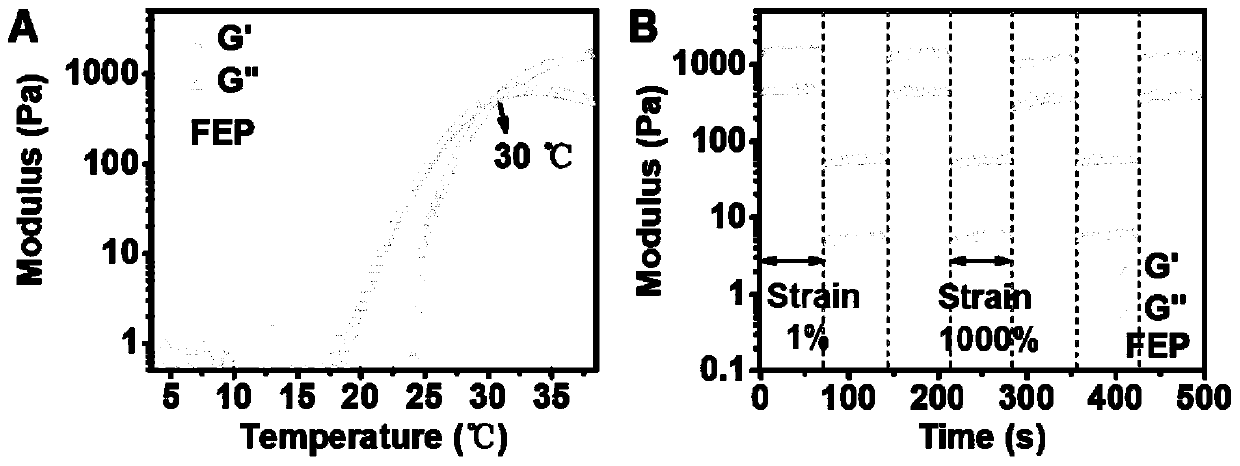

[0042] like figure 1 Shown, preparation method of the present invention specifically comprises the following steps:

[0043] 1) Cationic functionalized polyether polymer synthesis. Completely dissolve polyether F127 with a molar ratio of 1:(8~12):(8~12), p-toluenesulfonyl chloride and triethylamine in 100~150mL of anhydrous dichloromethane, and react at room temperature under nitrogen for 18 ~24 hours later, the prepolymer was obtained by extraction and precipitation, and then the prepolymer and cationic polymer with a molar ratio of 1: (1.5~4.5) were completely dissolved in 100~150mL N,N-dimethylformamide, After stirring at 60-65°C for 48-60 hours, the reaction product was dialyzed and purified in deionized water for 2-3 days, and freeze-dried for later use;

[0044] Preferably, the cationic functionalized polyether F127 in step 1) is ε-polylysine or polyethyleneimine functionalized polyether F127, wherein the molar ratio of cationic polymer to F127 is 2.5:1.

[0045] 2) S...

Embodiment 1

[0056] 1) Preparation of F127-PEI polymer: Dissolve polyether F127 with a molar ratio of 1:10:10, p-toluenesulfonyl chloride and triethylamine in 100 mL of anhydrous dichloromethane, and react at room temperature for 24 Hours later, the prepolymer was obtained by extraction and precipitation, and then the prepolymer and polyethyleneimine with a molar ratio of 1:2.5 were completely dissolved in 100mL N,N-dimethylformamide, and stirred at 60°C for 48 hours Finally, the reaction product F127-PEI was dialyzed and purified in deionized water for 3 days, and freeze-dried for later use;

[0057] 2) Preparation of APu polymer: Dissolve pullulan and sodium periodate at a molar ratio of 1:1 in 150mL deionized water, stir at room temperature for 12 hours in the dark; add sodium periodate Ethylene glycol with a molar ratio of 2:1 terminated the reaction. After stirring for 2 hours at room temperature, the reaction product APu was dialyzed and purified in deionized water for 3 days, and fr...

Embodiment 2

[0061] 1) Preparation of F127-PEI polymer: Dissolve polyether F127 with a molar ratio of 1:10:10, p-toluenesulfonyl chloride and triethylamine in 100 mL of anhydrous dichloromethane, and react at room temperature for 24 Hours later, the prepolymer was obtained by extraction and precipitation, and then the prepolymer and polyethyleneimine with a molar ratio of 1:2.5 were completely dissolved in 100mL N,N-dimethylformamide, and stirred at 60°C for 48 hours Finally, the reaction product F127-PEI was dialyzed and purified in deionized water for 3 days, and freeze-dried for later use;

[0062] 2) Preparation of APu polymer: Dissolve pullulan and sodium periodate at a molar ratio of 1:1 in 150mL deionized water, stir at room temperature for 12 hours in the dark; add sodium periodate Ethylene glycol with a molar ratio of 2:1 terminated the reaction. After stirring for 2 hours at room temperature, the reaction product APu was dialyzed and purified in deionized water for 3 days, and fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com