Adsorbent for adsorption of VOCs and preparation method of adsorbent

A technology of adsorbent and template agent, which is applied in the direction of separation methods, chemical instruments and methods, inorganic chemistry, etc., can solve the problem that the adsorption capacity of low-concentration organic waste gas cannot be effectively improved, the pore structure of silica gel material has little effect, and the long-term stability cannot be achieved. Application and other issues, to achieve the effect of good hydrothermal stability, moderate pore size, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] As introduced in the background technology, currently VOC adsorbents and their synthesis process generally have problems such as low adsorption capacity of organic waste gas, cumbersome and complicated process, and waste acid generation. In order to solve the above technical problems, in the first part of this disclosure In a typical embodiment, a kind of preparation method of the adsorbent for VOCs adsorption is provided, comprising the following steps:

[0028] (1) Mix the silicon source, aluminum source and template according to the set ratio, and self-pressure crystallize under the set temperature and pressure to generate VOCs adsorbent precursor 1;

[0029] (2) washing the adsorbent precursor 1, ion exchange, and then roasting to obtain the VOCs adsorbent precursor 2;

[0030] (3) Mix the obtained VOCs adsorbent precursor II with alumina, add water and knead, extrude, dry, and roast to obtain the VOCs adsorbent.

[0031] In one or more embodiments of the present d...

Embodiment 1

[0053] A preparation method for an adsorbent for VOCs adsorption, comprising the following steps:

[0054] (1) Silica gel (calculated as silica), sodium metaaluminate (calculated as alumina) and n-butylamine are used according to the set ratio (wherein, the molar ratio of feeding is silica: alumina=600, n-butylamine: Silica = 0.26,) mixed, self-pressure crystallization under the set temperature and pressure, crystallization temperature 165 ° C, crystallization pressure 0.8MPa, crystallization time 36h, to generate VOCs adsorbent precursor 1;

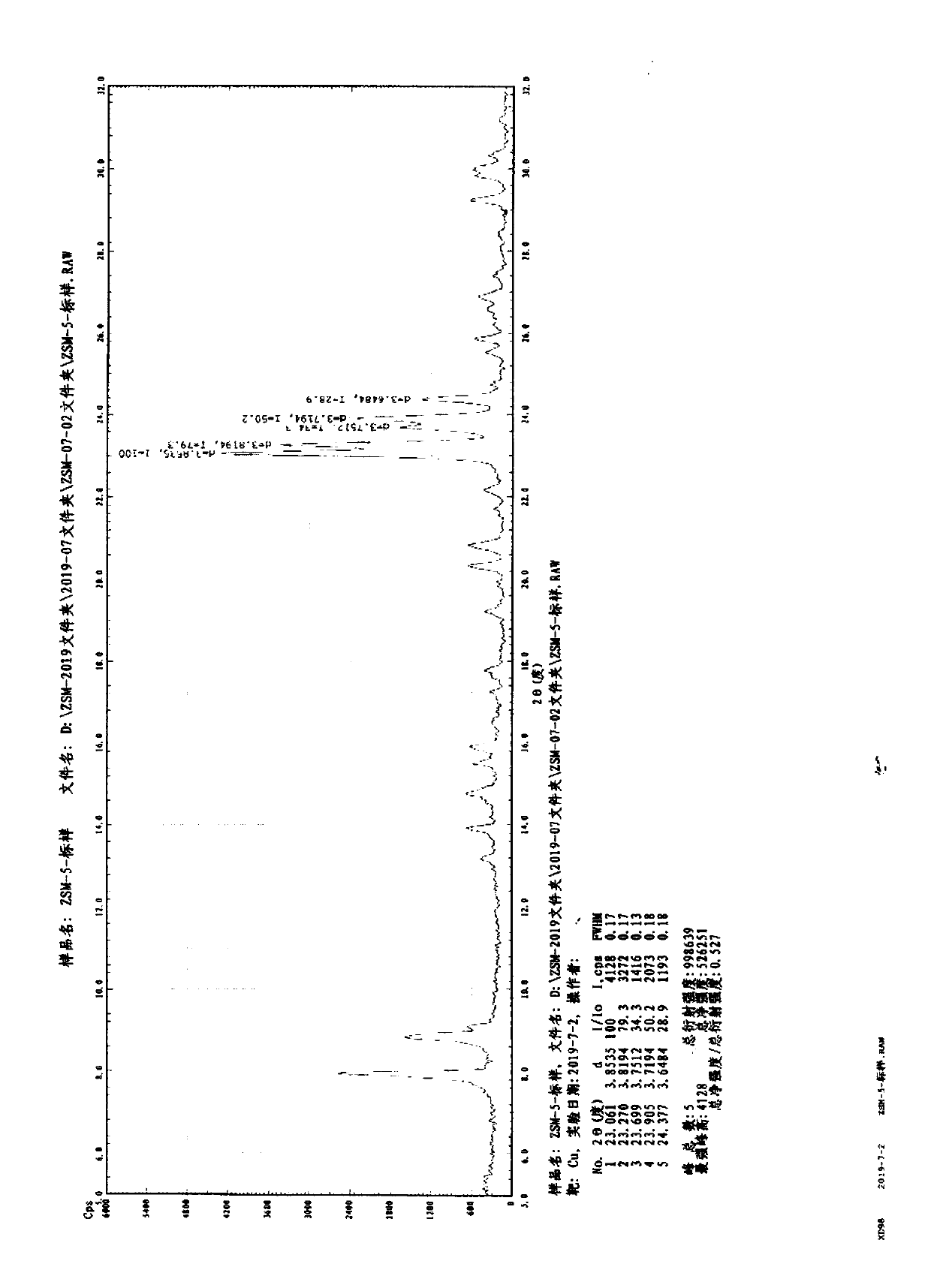

[0055] The VOCs adsorbent precursor that obtains this moment-relative crystallinity 90% (for standard sample, such as figure 1 shown);

[0056] (2) The adsorbent precursor 1 is washed with pure water, ion-exchanged, the exchange liquid is dilute hydrochloric acid, and then roasted, roasting conditions: roasting at 500°C for 8 hours under the condition of ventilation, to obtain the VOCs adsorbent precursor 2;

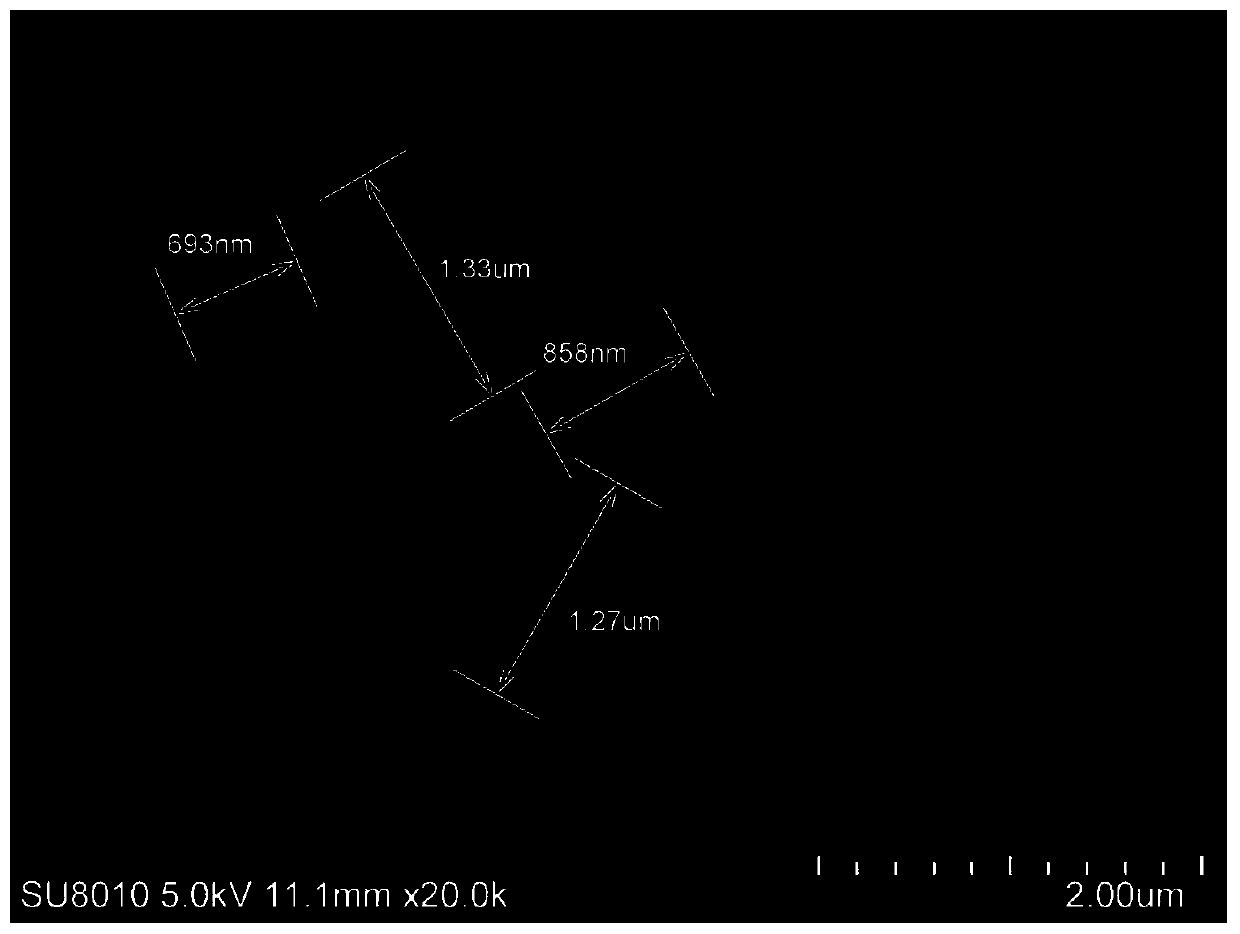

[0057] At this time, the ...

Embodiment 2

[0061] A preparation method for an adsorbent for VOCs adsorption, comprising the following steps:

[0062] (1) Mix silica sol, sodium metaaluminate and n-butylamine according to the set ratio (the molar ratio of feed is silica: alumina = 650, templating agent: silica = 0.31, ), at the set temperature and pressure Under self-pressure crystallization, the crystallization temperature is 166°C, the crystallization pressure is 0.85MPa, the crystallization time is 30h, and VOCs adsorbent precursor 1 is generated;

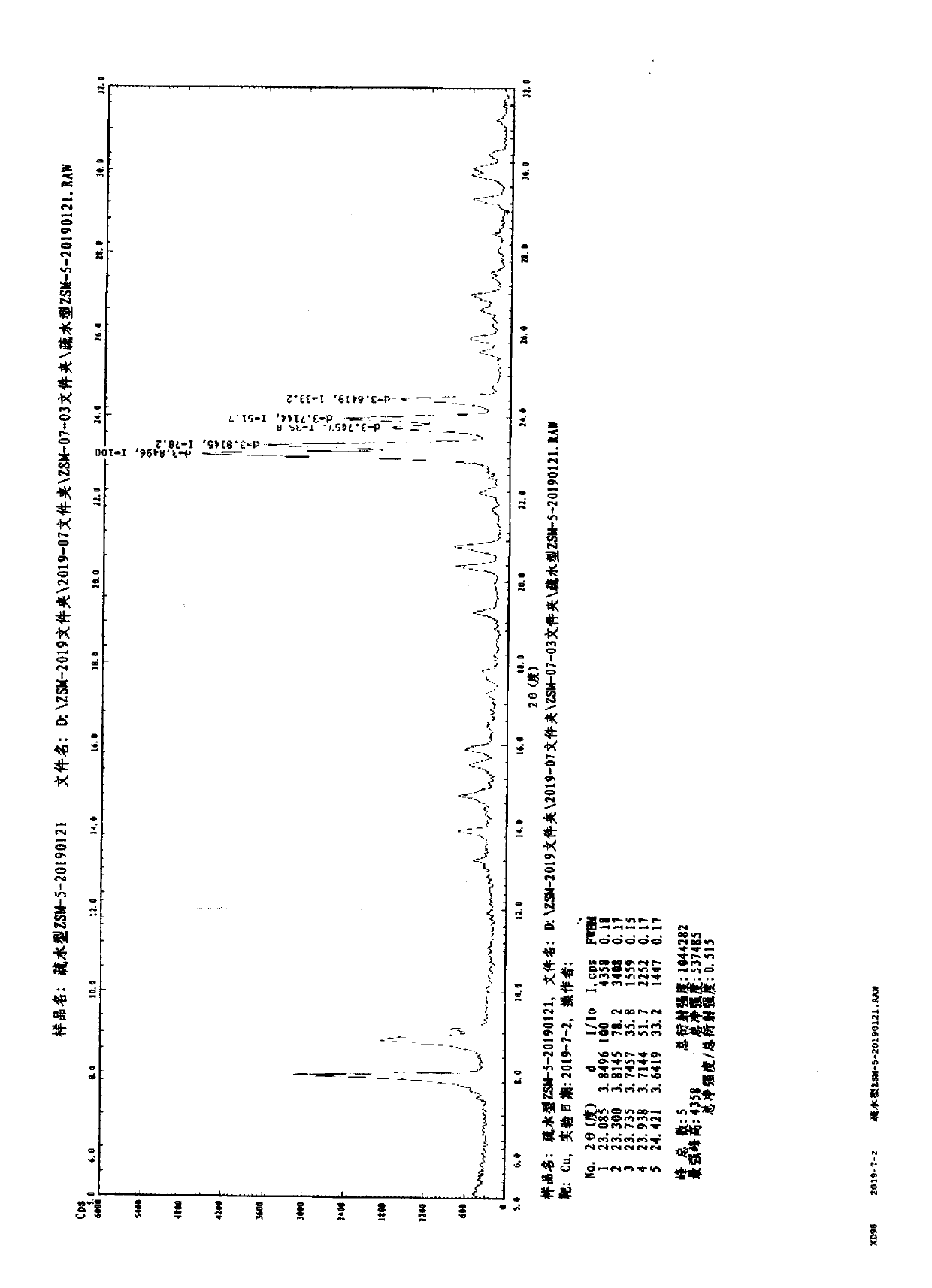

[0063] The VOCs adsorbent precursor obtained at this time has a relative crystallinity of 90% (against the standard sample);

[0064] (2) The adsorbent precursor 1 is washed with pure water, ion-exchanged, the exchange liquid is ammonium chloride, and then roasted, roasting conditions: roasting at 550°C for 5 hours under the condition of ventilation, to obtain the VOCs adsorbent precursor 2;

[0065] At this time, the mass percentage of sodium oxide in the product after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com