Preparation and application for straw cellulose/graphene oxide composite material

A technology of straw cellulose and composite materials, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve problems such as uneconomical and time-consuming, and achieve easy operation, preparation cost and energy consumption Low, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 Preparation of straw cellulose / graphene oxide composite material

[0040] (1) Graphite oxide adopts the modified Hummers method, 0.5 g of graphite oxide is added to 100 mL of deionized water and ultrasonically oscillated for 0.5 h. Then add 0.5mL of straw cellulose, and stir at room temperature for 10 minutes; then add a solution containing NaOH and urea, and continue stirring for 10 minutes to obtain a straw cellulose / graphene oxide mixture;

[0041] (2) Freeze the straw cellulose / graphene oxide mixture for 120 minutes, take it out and stir for 10 minutes, then add NaCl-containing HNO 3 , the centrifuged product was washed several times with deionized water, 50 o C vacuum drying, grinding to obtain straw cellulose / graphene oxide powder product.

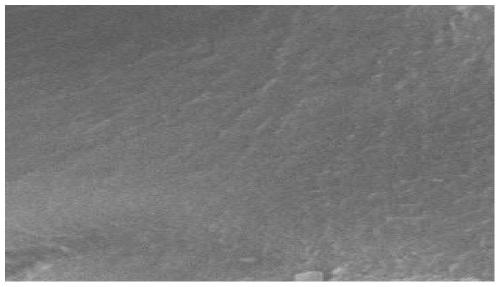

[0042] like figure 1 As shown, the prepared straw cellulose / graphene oxide composite material,

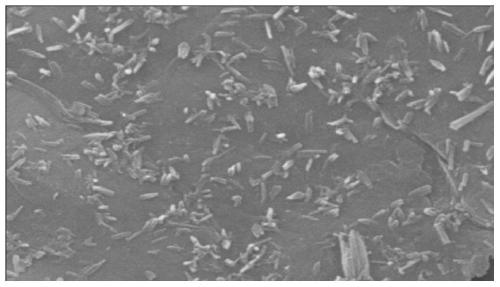

[0043] like figure 2 As shown, the prepared straw cellulose material,

[0044] like image 3 As shown, graphen...

Embodiment 2

[0045] Embodiment 2 to heavy metal Cd in water 2+ The removal experiment

[0046] Take 100mL of heavy metal Cd containing 50mg / L 2+ Put the solution in a 250mL Erlenmeyer flask, adjust the pH to 8 with nitric acid or sodium hydroxide, add 100mg of the straw cellulose / graphene oxide composite material prepared in Example 1, shake the solution for 1 hour at room temperature, and then centrifuge the solution . The separated supernatant was analyzed by ICP-MS for the remaining heavy metal Cd in the solution. 2+ The ion concentration was detected, and the detection results were compared with the Cd in the solution before adsorption. 2+ After comparing the initial concentrations of ions, the effect of the straw cellulose / graphene oxide composite on the heavy metal Cd 2+ The adsorption capacity is 49.86mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com