Silica with low particle size and high dispersion and high transparency for toothpastes and preparation method thereof

A silicon dioxide, highly dispersed technology, applied in the direction of silicon dioxide, silicon oxide, cosmetic preparations, etc., can solve the problems of easy interaction, difficulty in obtaining transparent toothpaste, and large difference in light transmittance, so as to reduce production costs , good market prospects, and the effect of high dispersion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

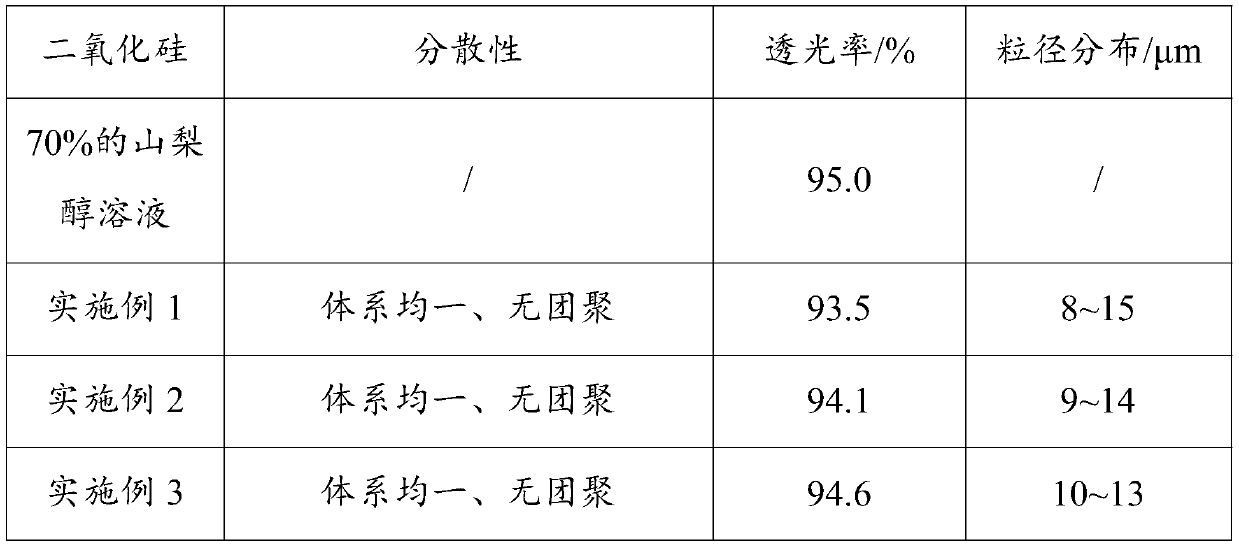

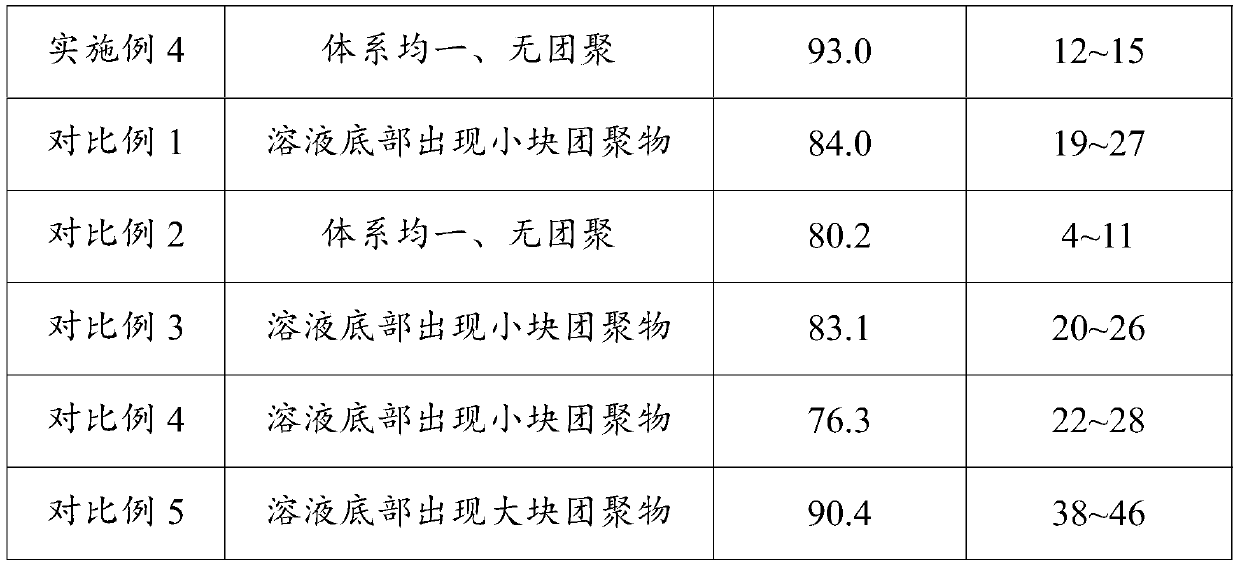

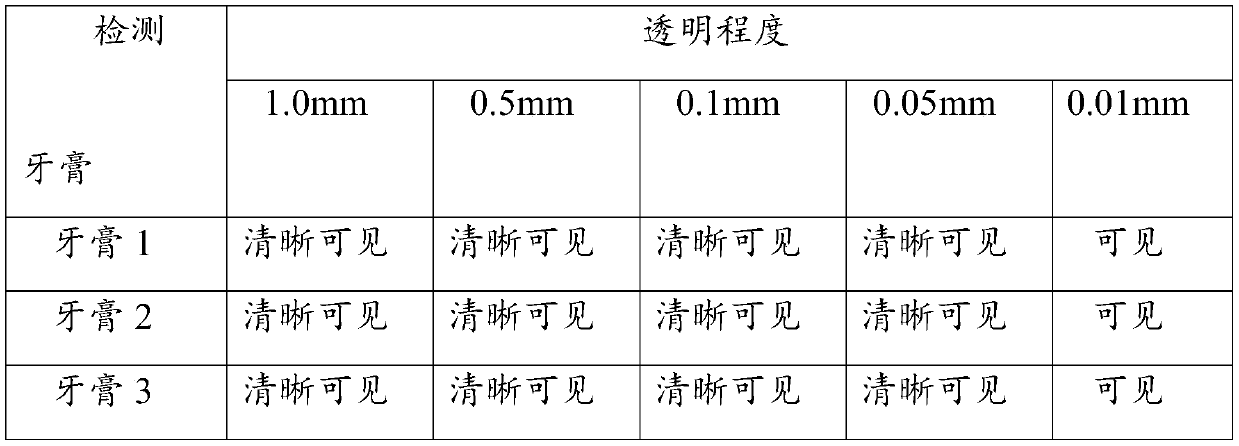

Examples

Embodiment 1

[0033] Example 1. Silica for toothpaste with low particle size, high dispersion and high transparency of the present invention and its preparation method

[0034] S1. Add polyethylene glycol with a molecular weight of 4000 to the sodium silicate solution with a concentration of 2.0mol / L. The amount of polyethylene glycol added is 4wt% of the sodium silicate solution. Stir and disperse evenly to obtain a sodium silicate mixture. solution;

[0035] S2, add 10m of sodium sulfate solution that mass percent concentration is 4.0% in reaction tank 3 , set the mixer frequency to 25Hz, start stirring, and raise the temperature to 70°C;

[0036] S3, under stirring, dropwise add sodium silicate mixed solution 8m 3 Carry out co-current neutralization reaction with sulfuric acid solution whose concentration is 8mol / L, control the flow velocity of sodium silicate mixed solution to be 13m 3 / h, the flow rate of sulfuric acid solution is 2.5m 3 / h, the pH value of the reaction process is ...

Embodiment 2

[0038] Embodiment 2. Silica for toothpaste with low particle size, high dispersion and high transparency of the present invention and its preparation method

[0039] S1. Add polyethylene glycol with a molecular weight of 6000 to the sodium silicate solution with a concentration of 3.5mol / L. The amount of polyethylene glycol added is 8wt% of the sodium silicate solution. Stir and disperse evenly to obtain a sodium silicate mixture. solution;

[0040] S2, adding mass percent concentration to the reaction tank is 12m of sodium sulfate solution of 6.0%. 3, set the mixer frequency to 35Hz, start stirring, and raise the temperature to 70°C;

[0041] S3, while stirring, add sodium silicate mixed solution 10m 3 Perform co-current neutralization reaction with a sulfuric acid solution with a concentration of 10mol / L, and control the flow rate of the sodium silicate mixed solution to 13m 3 / h, the flow rate of sulfuric acid solution is 3.5m 3 / h, the pH value of the reaction process ...

Embodiment 3

[0043] Example 3. Silica for toothpaste with low particle size, high dispersion and high transparency of the present invention and its preparation method

[0044] S1. Add polyethylene glycol with a molecular weight of 6000 to the sodium silicate solution with a concentration of 2.2mol / L. The amount of polyethylene glycol added is 6wt% of the sodium silicate solution. Stir and disperse evenly to obtain a sodium silicate mixture. solution;

[0045] S2, adding mass percent concentration in the reaction tank is 10m of sodium sulfate solution of 4.5% 3 , set the frequency of the mixer to 30Hz, start stirring, and raise the temperature to 75°C;

[0046] S3, while stirring, add sodium silicate mixed solution 10m 3 Carry out co-current neutralization reaction with sulfuric acid solution whose concentration is 8mol / L, control the flow velocity of sodium silicate mixed solution to be 14m 3 / h, the flow rate of sulfuric acid solution is 3.5m 3 / h, the pH value of the reaction process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Consistency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com