Construction method of effective component prediction model for silage corn and application thereof

A technology for silage corn and nutritional components, which is applied in the direction of measuring devices, analysis materials, and material analysis through optical means, which can solve the problem that the nutritional components of silage corn cannot be quickly and accurately measured, and achieve saving of feeding costs and low detection costs , The effect of no reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Utilize chemical analysis method to analyze the nutrient composition of silage corn

[0038] 1. Pretreatment of Silage Corn Samples

[0039] Put the silage corn into an electric blast drying oven, and dry it in an oven at 105°C until the water content is reduced to about 1.6-12.8%, then use a high-speed grinder to crush the sample, and then use a sampling sieve to sieve the dried straw. The 40-mesh sample was stored in a ziplock bag, and the subsequent steps were carried out after 24 hours of equilibrating the moisture.

[0040] 2. Determination of nutrient content

[0041] For determination of crude protein, refer to "Determination of Crude Protein in GB / T 6432-1994 Feed"; for determination of crude fat, refer to "Determination of Crude Fat in Feed"; For the determination of starch, refer to "ZYA-SL-005-2017 Anthrone colorimetric method for the determination of starch"; for neutral detergent fiber, refer to "GB / T20806-2006 Determination of neutral deter...

Embodiment 2

[0046] Example 2: Near-infrared spectrum collection of silage corn

[0047] Put the silage corn sample with a particle size of 40 mesh into a sample cup with a diameter of 9.4 cm and a depth of 4.8 cm. The volume of the sample is about 1 / 2 to 2 / 3 of the cup body, and gently put it into the cup cover to ensure that the bottom of the sample cup is No gaps.

[0048] The near-infrared spectrum of the silage corn samples was collected by using the grating continuous spectrum mode of the Spectrastar 1400XL-3 near-infrared spectrometer of Unity Company in the United States in the range of wavenumbers from 1400nm to 2500nm. The spectral collection rate is 45 degs / sec, the wavelength accuracy is 1nm, and the sample is scanned twice.

[0049] The main components of silage corn are crude protein, crude fat, water, starch, neutral detergent fiber, and acid detergent fiber. These components have strong absorption in the near-infrared region.

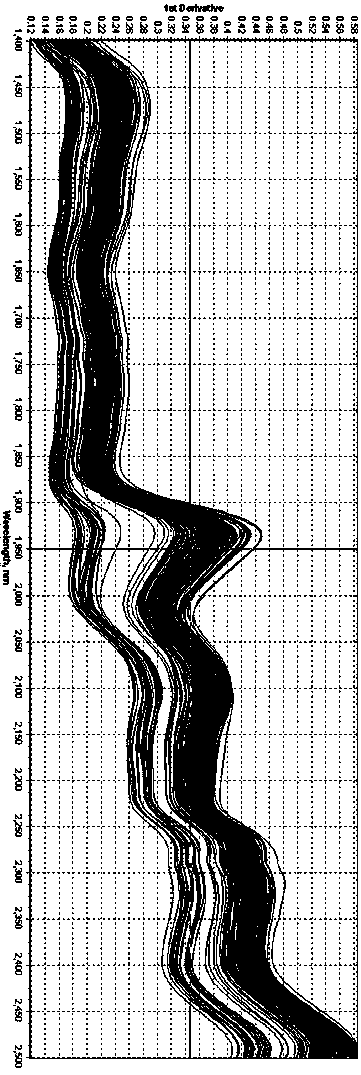

[0050] Such as figure 1As shown, the main c...

Embodiment 3

[0051] Example 3: Analysis of near-infrared spectral characteristics of silage corn

[0052] Select 154 representative samples from various places in Henan Province, detect and analyze the content of each active ingredient according to the method described in Example 1, and collect the near-infrared spectra of each sample according to the method in Example 2.

[0053] Then use the Ucal data analysis software of Unity Company in the United States to perform detrend correction (Detrend) and standard normal variable transformation (SNV) preprocessing on the diffuse reflectance raw spectra of the obtained silage corn samples.

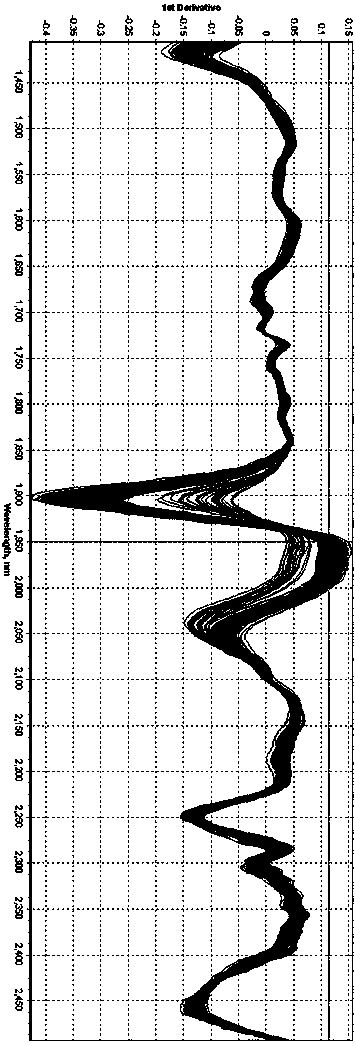

[0054] The spectrogram after detrend correction (Detrend) and standard normal variable transformation (SNV) preprocessing is as follows figure 2 shown.

[0055] From figure 2 It can be seen that the preprocessed spectrum can accurately find that the region that contributes to the accuracy of the model is between 1900nm and 2500nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com