Fuel cell device, and method for removal of ammonia nitrogen and regeneration of ferric iron

A fuel cell and fuel cell system technology, which is applied in the fields of biotechnology and environmental protection, can solve the problems of loss, increased wastewater treatment cost, substandard effluent color, etc., and achieves the effects of cost saving, low treatment cost and high removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

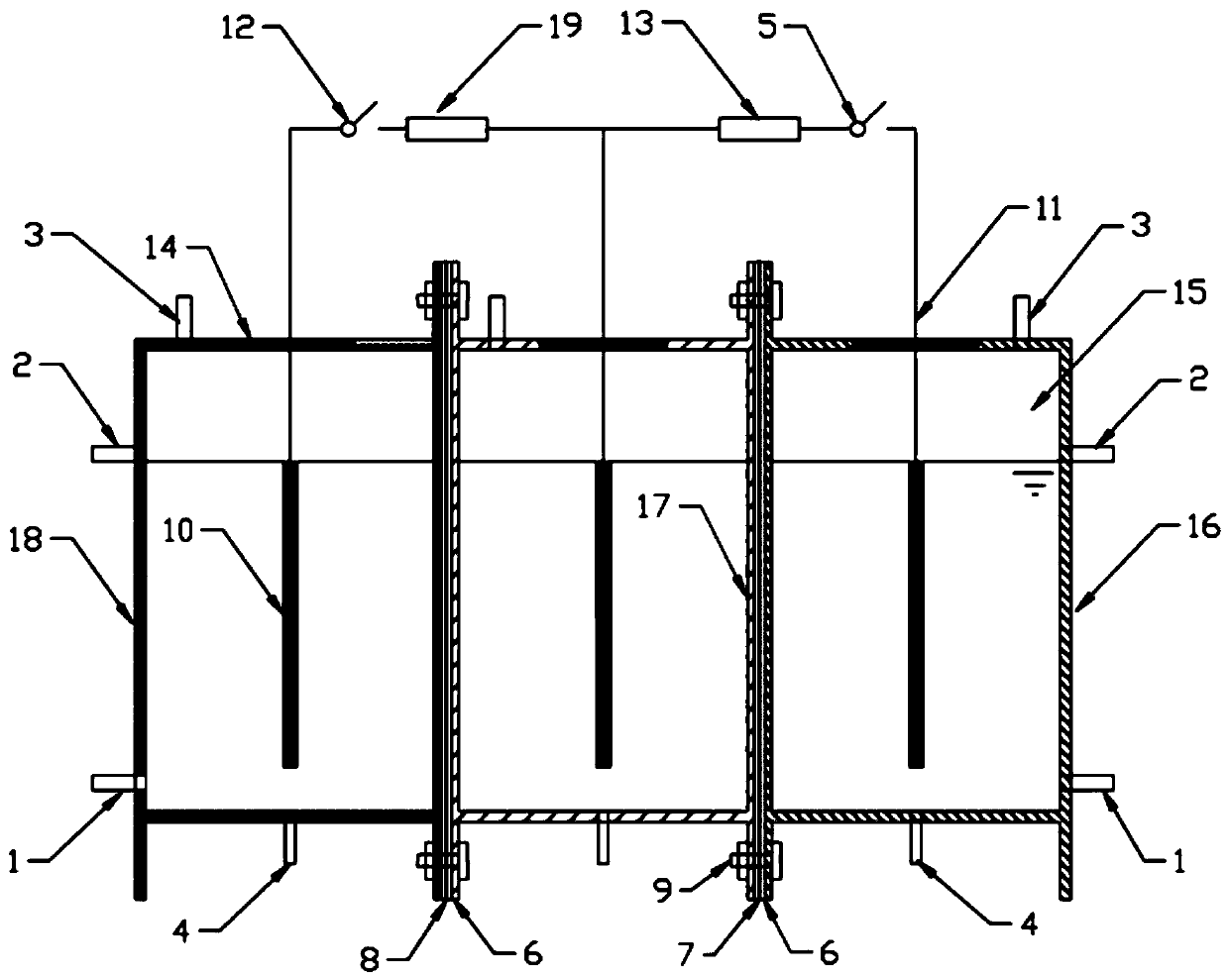

[0028] Such as figure 1 As shown, the purpose of the present invention is to solve the problems of existing anaerobic iron ammonium oxidation technology that the effluent contains high concentration of iron ions and iron regeneration is difficult, and to provide a fuel cell device and a method for ammonia nitrogen removal and ferric iron regeneration.

[0029] A fuel cell device, the main device of which is a three-chamber microbial fuel cell system, which includes three independent reaction areas of anaerobic ammonia oxidation unit, iron redox unit and photobiological reaction unit, which are connected by bolts 9 . The volume ratio of the anammox unit, the iron redox unit and the photobiological reaction unit is 1:1:2. The anammox unit and the iron redox unit are separated by a cation exchange membrane 7 , and the iron redox unit and the photobiological reaction unit are separated by an anion exchange membrane 8 . The anaerobic ammonia oxidation unit, the iron redox unit and...

Embodiment 2

[0043] Such as figure 1 As shown, a fuel cell device, the main device is composed of a three-chamber microbial fuel cell and an external circuit. The anammox unit is made of opaque materials, the iron redox unit is made of light-transmitting materials, and the photobiological reaction unit is made of materials with visible light cut-off infrared light and high transparency. The three units are respectively provided with a water inlet pipe 1, a water outlet pipe 2, an exhaust port 3 and an emptying pipe 4. External circuits are respectively arranged between the anaerobic ammonia oxidation unit and the iron redox unit, between the iron redox unit and the photobiological reaction unit, and resistors and switches are respectively arranged in the external circuits. Carbon-based electrodes 10 are installed in the three reaction units, and the carbon-based electrodes 10 are connected with wires outside the device through titanium wires 11 to form a loop. The anammox unit and the ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com