Self-lubricating hydrophobic silicon-acrylic emulsion, and preparation method and application thereof

A silicone-acrylic emulsion, self-lubricating technology, applied in the field of coatings, can solve the problems of cumbersome practical application, easy loss, initial release has not been paid attention to and solved, and achieves stable and low adhesion characteristics, good anti-fouling performance, long-lasting The effect of stabilizing the antifouling behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A self-lubricating hydrophobic silicone acrylic emulsion, in parts by weight, comprises the following components:

[0063] 90 parts of mixed monomers, 1.0 parts of hydrophobic lubricants, 1.0 parts of functional monomers, 0.5 parts of coupling monomers, 0.2 parts of crosslinking aids, 2 parts of emulsifiers, 1.0 parts of co-emulsifiers, 0.75 parts of initiators, pH buffer 0.5 parts of agent, 100 parts of deionized water; the mixed monomer includes hard monomer and soft monomer, wherein the hard monomer is styrene, and the soft monomer is butyl acrylate.

[0064] The mass ratio of the hard monomer and the soft monomer in the mixed monomer is 5.5:3.0.

[0065] The hydrophobic lubricant is polydimethylsiloxane.

[0066] The functional monomer is acrylic acid.

[0067] The coupling monomer is γ-methacryloxypropyltrimethoxysilane.

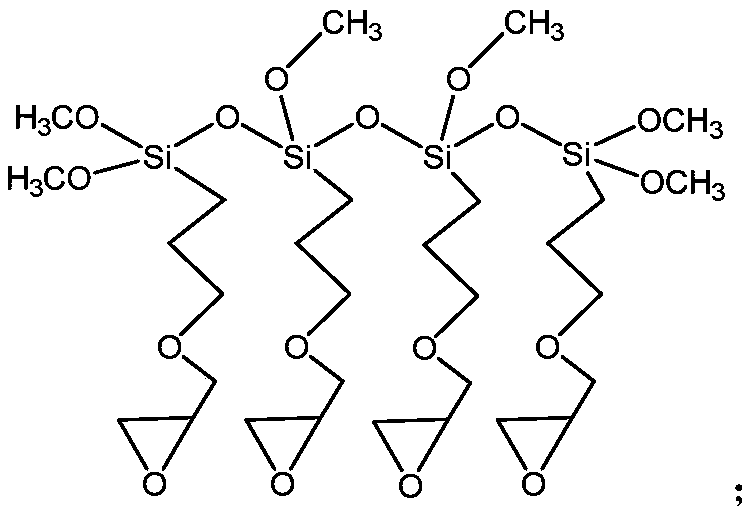

[0068] The crosslinking aid is a glycidyl ether siloxane oligomer, and its structural formula is:

[0069]

[0070] The emulsifier is all...

Embodiment 2

[0087] A self-lubricating hydrophobic silicone acrylic emulsion, in parts by weight, comprises the following components:

[0088] 100 parts of mixed monomer, 4 parts of hydrophobic lubricant, 2 parts of functional monomer, 2 parts of coupling monomer, 0.4 parts of crosslinking aid, 3 parts of emulsifier, 2 parts of co-emulsifier, 1 part of initiator, pH buffer 1 part of agent, 120 parts of deionized water; the mixed monomer includes hard monomer and soft monomer, wherein the hard monomer is methyl methacrylate, and the soft monomer is ethyl acrylate.

[0089] The mass ratio of hard monomer and soft monomer in the mixed monomer is 6:4.

[0090] The hydrophobic lubricant is polydimethylsiloxane terminated by silanol, and its viscosity is 100-500mm 2 / s (25°C).

[0091] The functional monomer is methacrylic acid;

[0092] The coupling monomer is γ-methacryloxypropyltriisopropoxysilane.

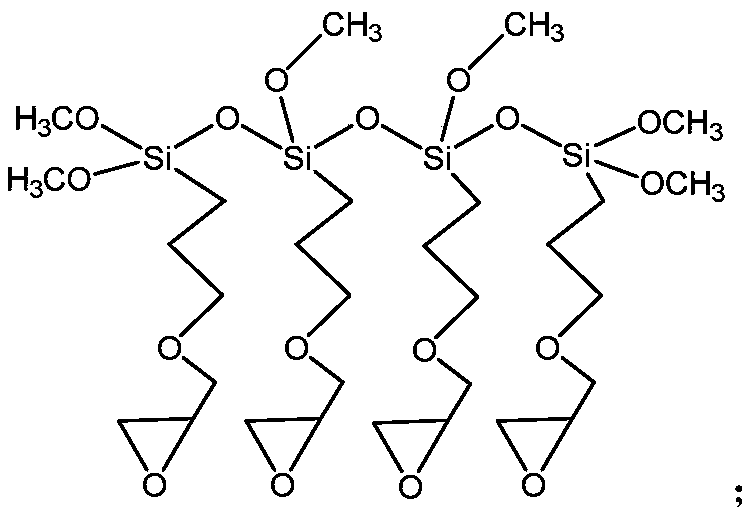

[0093] The crosslinking aid is a glycidyl ether siloxane oligomer, and its structural for...

Embodiment 3

[0112] A self-lubricating hydrophobic silicone acrylic emulsion, in parts by weight, comprises the following components:

[0113] 120 parts of mixed monomer, 6.0 parts of hydrophobic lubricant, 4.0 parts of functional monomer, 3.0 parts of coupling monomer, 1 part of crosslinking aid, 4 parts of emulsifier, 3.0 parts of co-emulsifier, 2 parts of initiator, pH buffer 2 parts of agent and 150 parts of water; the mixed monomer includes hard monomer and soft monomer, wherein the hard monomer is styrene, and the soft monomer is 2-ethylhexyl acrylate.

[0114] The mass ratio of the hard monomer and the soft monomer in the mixed monomer is 7.0:4.5.

[0115] The hydrophobic lubricant is polydimethylsiloxane.

[0116] The functional monomer is 2 parts of acrylic acid and 2 parts of methacrylic acid.

[0117] The coupling monomer is selected from 1 part of γ-methacryloxypropyl trimethoxysilane and 2 parts of γ-methacryloxypropyl triisopropoxysilane.

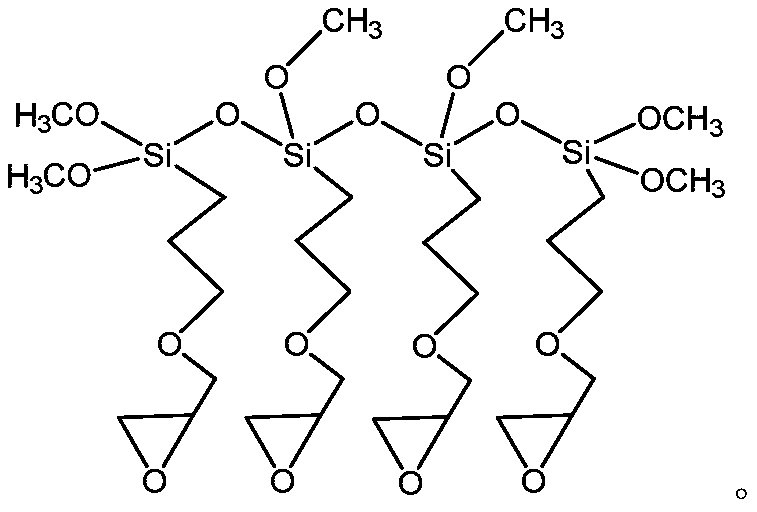

[0118] The crosslinking aid is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com