Method preparing plastic wood particles through waste resin

A technology of waste resin and plastic wood, which is applied in the field of composite materials, can solve the problems of flame retardancy, aging, and easy breeding of bacteria in plastic wood materials, achieve good economic benefits and social value, improve flame retardancy, and increase application potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

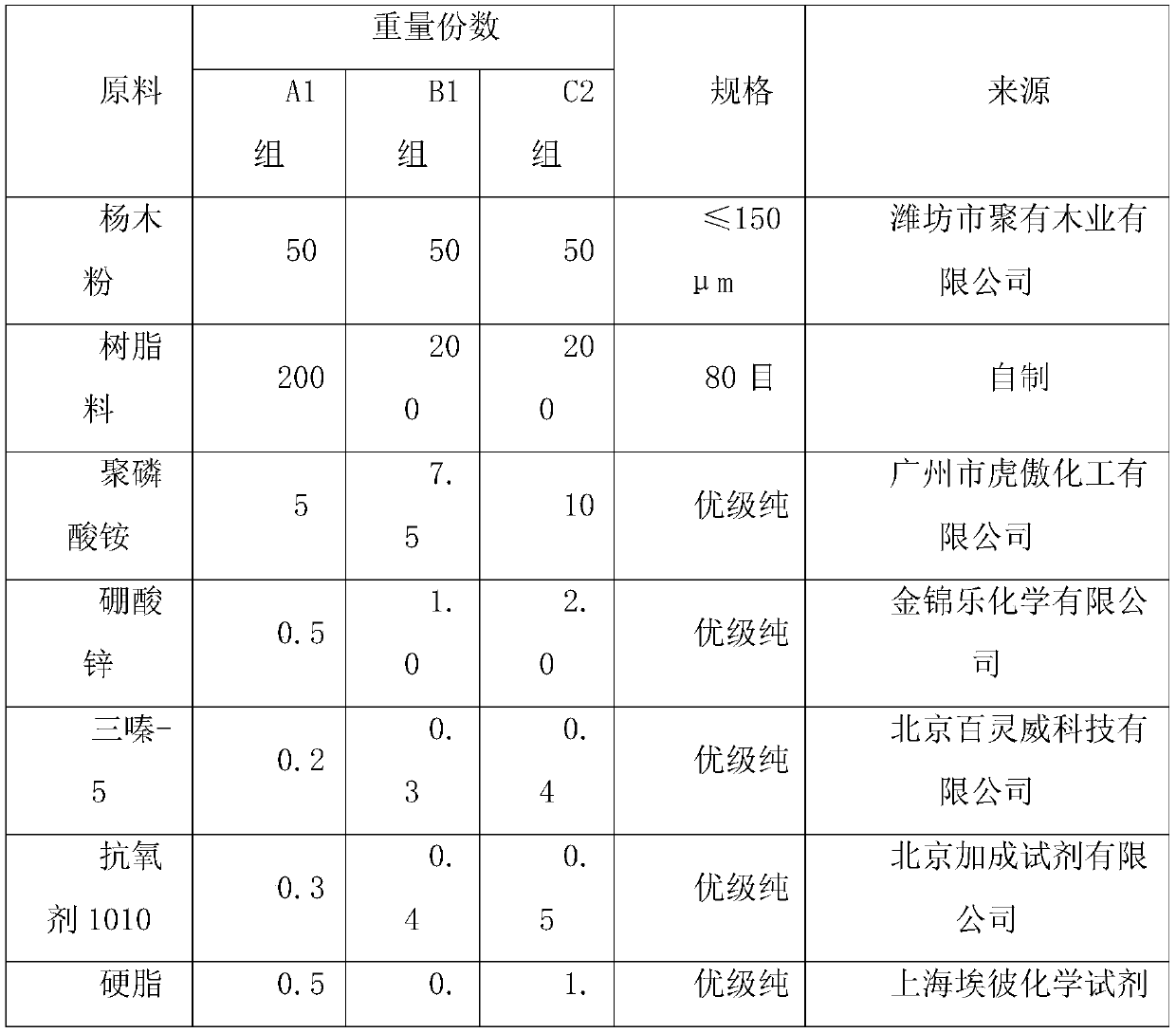

Embodiment 1

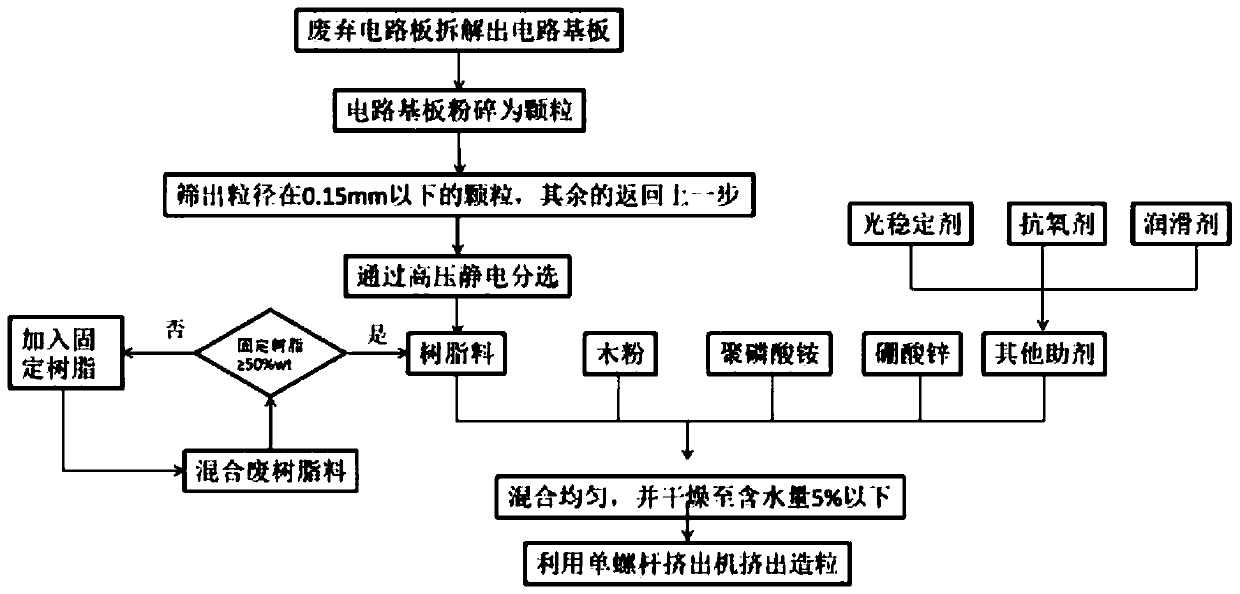

[0033] See figure 1 , a kind of method that utilizes waste resin to prepare wood-plastic particle, first, reclaim mixed waste resin material from waste circuit board:

[0034] Step 1: Disassemble the waste circuit board into the circuit board using a hot air dismantling machine. This step is to remove the electronic components on the circuit board and remove the solder;

[0035] The second step: the circuit board will be crushed by a hammer crusher, which has a simple structure, a large crushing ratio, and high crushing efficiency;

[0036] Step 3: Use an electric vibrating sieve to screen out particles with a particle size below 0.15mm, and repeat the second step for the remaining particles;

[0037] The fourth step: use a high-voltage electrostatic separator to separate the particles obtained in the third step into metal materials and mixed waste resin materials.

[0038] Preparation of wood plastic particles by mixing waste resin materials:

[0039] S1: Raw material prepar...

Embodiment 2

[0058] See figure 1 , a kind of method that utilizes waste resin to prepare wood-plastic particle, first, reclaim mixed waste resin material from waste circuit board:

[0059] Step 1: Disassemble the waste circuit board into the circuit board using a hot air dismantling machine. This step is to remove the electronic components on the circuit board and remove the solder;

[0060] The second step: the circuit board will be crushed by a hammer crusher, which has a simple structure, a large crushing ratio, and high crushing efficiency;

[0061] Step 3: Use an electric vibrating sieve to screen out particles with a particle size below 0.15mm, and repeat the second step for the remaining particles;

[0062] The fourth step: use a high-voltage electrostatic separator to separate the particles obtained in the third step into metal materials and mixed waste resin materials.

[0063] Preparation of wood plastic particles by mixing waste resin materials:

[0064] S1: Raw material prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com