High-yield glutamine transaminase strain and application thereof

A technology of transaminase strains and glutamine, applied in the direction of bacteria, microorganisms, biochemical equipment and methods, etc., can solve the problems of incomplete activity and affect the application of glutamine transaminase, so as to reduce production costs and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

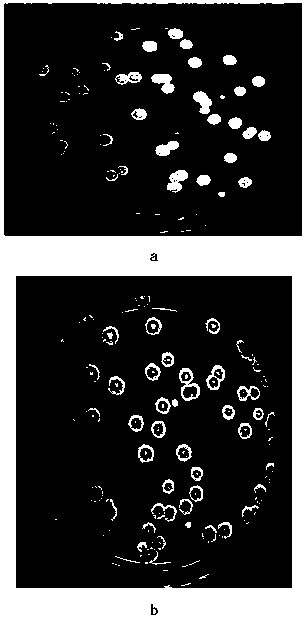

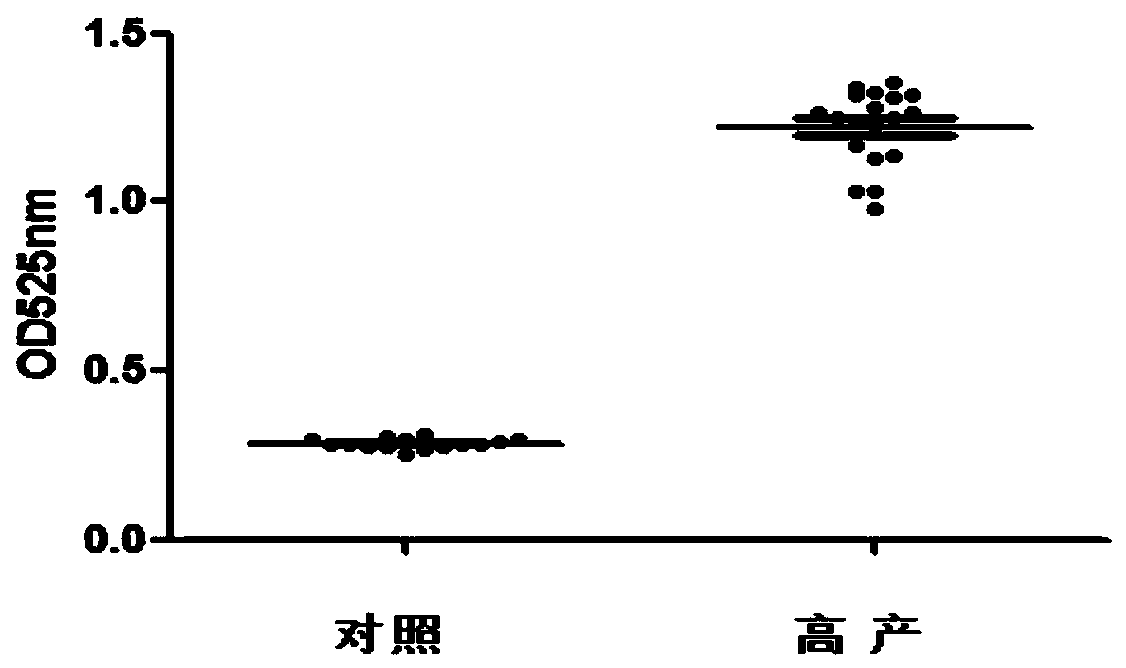

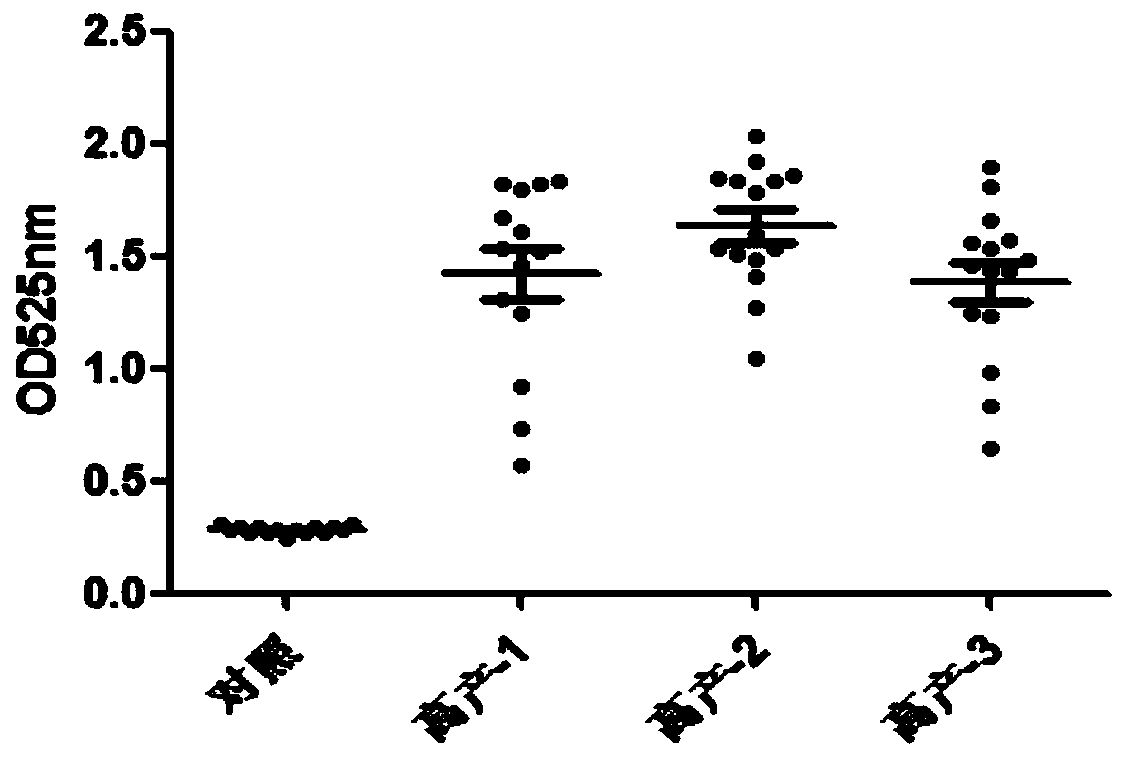

Image

Examples

Embodiment 1

[0031] (1) Gao's No. 1 culture medium for preparing the high-yield transglutaminase bacterial strain Streptomyces mobaraensis of the present invention, comprises the raw material composition of following weight ratio: agar: 2%; Starch: 2%; Potassium nitrate: 1%; Potassium: 0.5%; Sodium Chloride: 0.5%; Magnesium Sulfate Heptahydrate: 0.5%; Ferrous Sulfate Heptahydrate: 0.01%; pH: 7.4.

[0032] The method for preparing the above-mentioned Gao's No. 1 medium may further comprise the steps:

[0033] ①. Weigh 2% agar, 2% starch, 1% potassium nitrate, 0.5% dipotassium hydrogen phosphate, 0.5% sodium chloride, 0.5% magnesium sulfate heptahydrate, and 0.01% ferrous sulfate heptahydrate.

[0034] ②. After making up the volume with water, adjust the pH to 7.4, and sterilize under high temperature and high pressure at 121°C for 20 minutes.

[0035] ③. Pour the prepared culture medium into each petri dish at a volume of 20mL / dish (the diameter of the petri dish is 90mm) and wait to cool ...

Embodiment 2

[0038] (2) prepare the seed culture medium and fermentation medium of the high-yield transglutaminase bacterial strain Streptomyces mobaraensis of the present invention, comprise the raw material composition of following weight ratio: glycerol 2%; Yeast extract 0.6%; Fish meal peptone 2.5%; Magnesium sulfate heptahydrate 2%, dipotassium hydrogen phosphate 2%, and the rest is pure water; pH is 7.4.

[0039] The method for preparing above-mentioned seed medium, fermentation medium:

[0040] ①. Weigh 2% agar, 2% glycerin, 0.6% yeast extract, 2.5% fish powder peptone, 2% dipotassium hydrogen phosphate, 2% magnesium sulfate heptahydrate; among them, add 1% accelerator to each bottle of fermentation medium.

[0041] ②. After making up the volume with water, adjust the pH to 7.4, and sterilize under high temperature and high pressure at 121°C for 20 minutes.

[0042] ③. Cool the prepared medium to room temperature for later use.

Embodiment 3

[0043] Embodiment 3 prepares the reagent of high-yield transglutaminase bacterial strain of the present invention:

[0044] (1) Preparation of reagents A and B

[0045] Reagent A (reaction solution): containing 0.2M Tris-HCl, 0.1M hydroxylamine hydrochloride, 0.01M reduced glutathione, 0.03M Na-CBZ-Gln-Gly, pH 6.0.

[0046]Reagent B (Stop Solution): Mix the following three components in a volume ratio of 1:1:1. 3mol / L HCl, 12% trichloroacetic acid (W / V), 5% ferric chloride (W / V).

[0047] (2) Carry out enzyme activity detection to bacterial strain of the present invention by standard hydroxamate assay method, and its step is: get 2ml reagent A liquid and reagent B liquid respectively and add in ① and ② two grinding mouth test tubes respectively, 37 ℃ of insulations 15 Minutes, add 0.2ml enzyme solution, react for 10 minutes, add 2ml reagent B solution to ① test tube to stop the reaction, add 2ml reagent A solution to ② reagent test tube, use ② test tube reaction solution as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com