Multistage-decontamination-based production method of delicious and fragrant low-salt Pixian thick broad-bean sauce

A production method and watercress technology are applied in the production of fresh-flavored and low-salt Pixian watercress to improve the flavor quality of Pixian watercress, and can solve the deterioration of flavor, the reduction of the content of biological active substances in Pixian watercress, and the restriction of the use of Pixian watercress. problems such as quantity and market promotion, to achieve the effect of prolonging the shelf life and increasing the source of umami

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Pretreatment of Pixian Douban

[0033] In order to ensure the effect of the subsequent ultra-high pressure treatment process and avoid the influence of Pixian Douban due to product characteristics (semi-solid, containing broad bean, water, pepper, salt, etc.), high-shear homogenizer and enzymatic treatment are required first.

[0034] (1) Add 0.05kg / ton xylanase and pectinase and 0.01-0.02g / L polylysine to Pixian Douban.

[0035] Wherein the mass ratio of xylanase and pectinase is 1:1; Gluease XXL / SP~L.

[0036] (2) Process Pixian watercress with an ultra-high shear homogenizer, in which the rotation speed reaches more than 50,000 rpm (homogenization time is not less than 10 minutes), and the linear speed of the stirring blade tip exceeds 60 m / s, making Pixian In the narrow gap between the stator and the rotor, the watercress is subjected to comprehensive effects such as strong mechanical and hydraulic shearing, centrifugal extrusion, liquid layer friction, impact ...

Embodiment 2

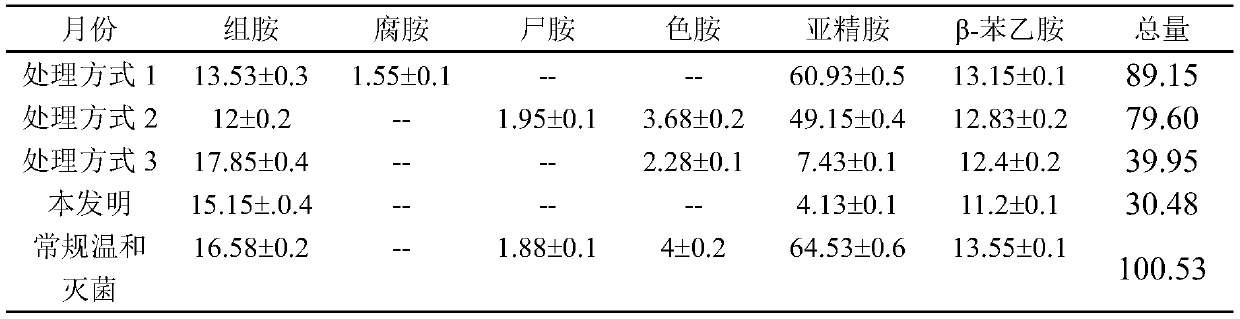

[0051] Example 2 Comparison of Biogenic Amine Content and Flavor in Pixian Douban Samples by Different Treatment Methods Treatment Method 1: Enzymolysis and high-pressure homogenization of fermented Pixian Douban

[0052] Processing method 2: Enzymolysis and high-pressure homogenization of the fermented Pixian Douban + Lushi's combined yeast fermentation

[0053] Processing method 3: Enzymolysis and high-pressure homogenization of fermented Pixian watercress + yeast fermentation + high-pressure pulse sterilization

[0054] Treatment method 4 (that is, the present invention): Enzymolysis and high-pressure homogenization of fermented Pixian watercress + yeast fermentation + high-pressure pulse sterilization + ultra-high pressure treatment

[0055] Routine mild sterilization: keep the fermented Pixian Doubanjiang at 66°C for about 2 days.

[0056] The results are shown in Table 1. Generally speaking, the higher the content of biogenic amines, the greater the risk of food safety....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com