Catalyst with non-noble metal nanoclusters confined and stabilized in silicalite-1 molecular sieve pore channels, and preparation method and application thereof

A non-precious metal, nano-cluster technology, used in molecular sieve catalysts, catalyst activation/preparation, carbon-based compound preparation, etc., can solve the problems of reducing the catalytic activity of metal nanoclusters, reducing the structural stability of molecular sieves, etc., to achieve excellent thermal stability , excellent catalytic performance, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] For any person skilled in the art, without departing from the scope of the technical solution of the present invention, the technical content disclosed above can be used to make many possible changes and modifications to the technical solution of the present invention, or be modified into equivalent changes, etc. effective example. Therefore, any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present invention should still fall within the protection scope of the technical solution of the present invention.

[0035] The present invention is described in detail below through specific examples, but the present invention is not limited to these examples.

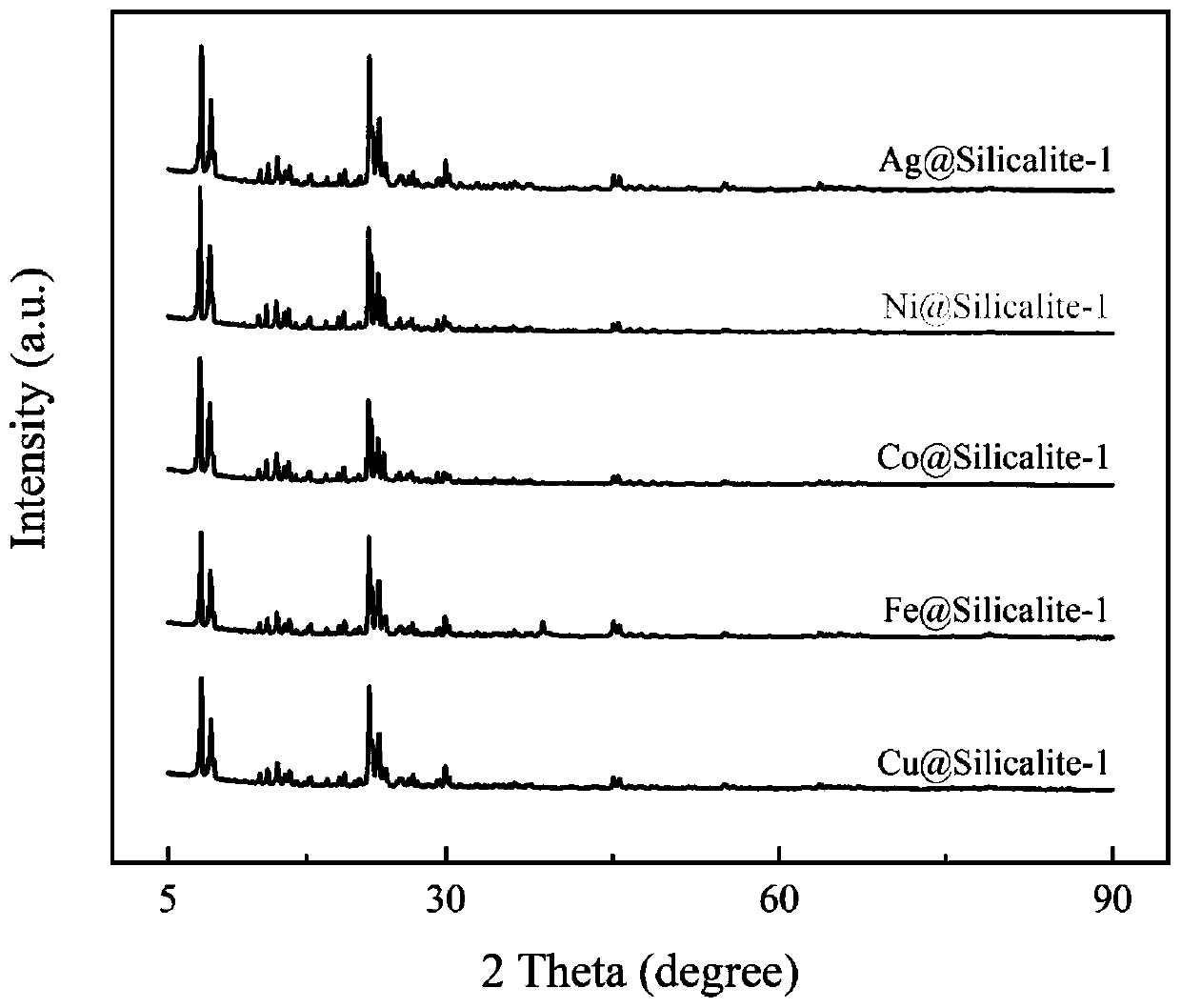

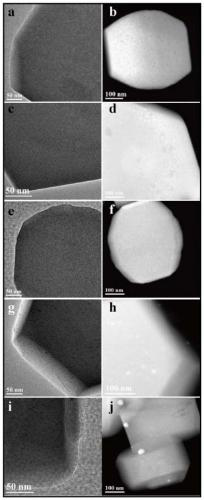

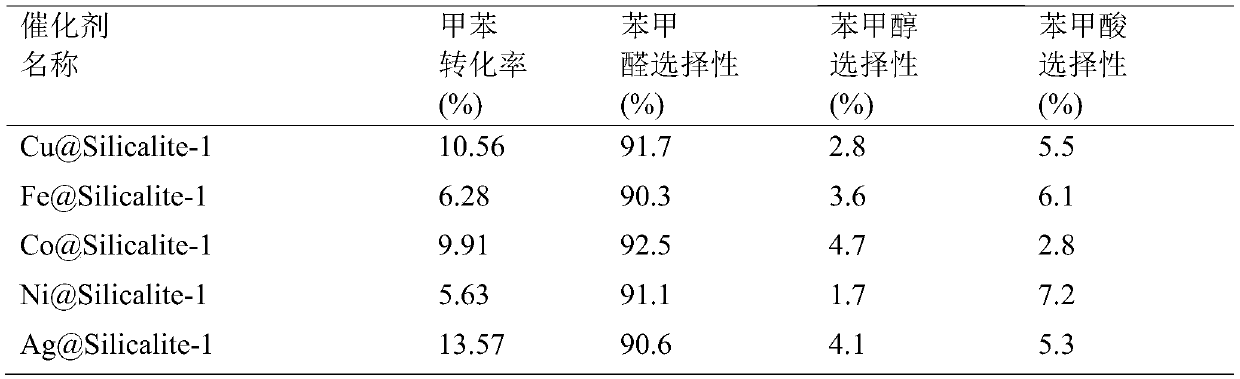

[0036] Example 1

[0037] Add 8g of tetraethyl orthosilicate (TEOS) into a mixed solution of 13g of tetrapropylammonium hydroxide (TPAOH) aqueous solution and 13g of water, stir at 25°C for 3h to obtain a transparent solution A; add 0.01g...

Embodiment 2

[0039] Add 8g of tetraethyl orthosilicate (TEOS) into a mixed solution of 15g of tetrapropylammonium hydroxide (TPAOH) aqueous solution and 15g of water, stir at 25°C for 3h to obtain a transparent solution A; add 0.01g of ferric nitrate Add it to the mixture of 0.1mL ethylenediamine and 1mL aqueous solution, and continue stirring at 25°C for 3h to obtain a transparent solution B; after that, slowly add the obtained solution B into solution A under stirring at 25°C, and then Continue to stir for 3h; after adding 0.05g of sodium hydroxide solid, continue to stir for 3h, the molar ratio of each component in the initial mixture solution in the reaction system is SiO 2 :TPAOH:H 2 O:Fe:NaOH=1:0.435:35.781:0.0049:0.026. The resulting mixture solution was transferred to a 100mL stainless steel reaction kettle, and then the reaction kettle was placed in a 170°C oven for crystallization for 168 hours; after the crystallization was completed, the solid product was separated by centrifu...

Embodiment 3

[0041] Add 8g of tetraethyl orthosilicate (TEOS) into a mixed solution of 18g of tetrapropylammonium hydroxide (TPAOH) aqueous solution and 18g of water, stir at 25°C for 3h to obtain a transparent solution A; add 0.01g of cobalt nitrate Add to the mixture of 0.2mL ethanolamine and 1mL aqueous solution, and continue to stir at 25°C for 3h to obtain a transparent solution B; after that, slowly add the obtained solution B into solution A under stirring at 25°C, and then continue to stir 3h; After adding 0.15g potassium hydroxide solid, continue stirring for 3h, the molar ratio of each component in the initial mixture solution in the reaction system is SiO 2 :TPAOH:H 2 O:Co:KOH=1:0.482:38.954:0.0052:0.039. The resulting mixture solution was transferred to a 100mL stainless steel reaction kettle, and then the reaction kettle was placed in a 170°C oven for crystallization for 168 hours; after the crystallization was completed, the solid product was separated by centrifugation, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com