Method for preparing 1-amino-4-naphthalene sulfonic acid sodium salt

A technology of sodium naphthalenesulfonate and amino, which is applied in the field of preparing sodium 1-amino-4-naphthalenesulfonate, can solve the problems of high sulfonation reaction temperature, easy loss of solvent, cumbersome process route, etc., and achieve high product selectivity and The effect of product purity, avoiding excessive sulfonation temperature, and shortening the preparation process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

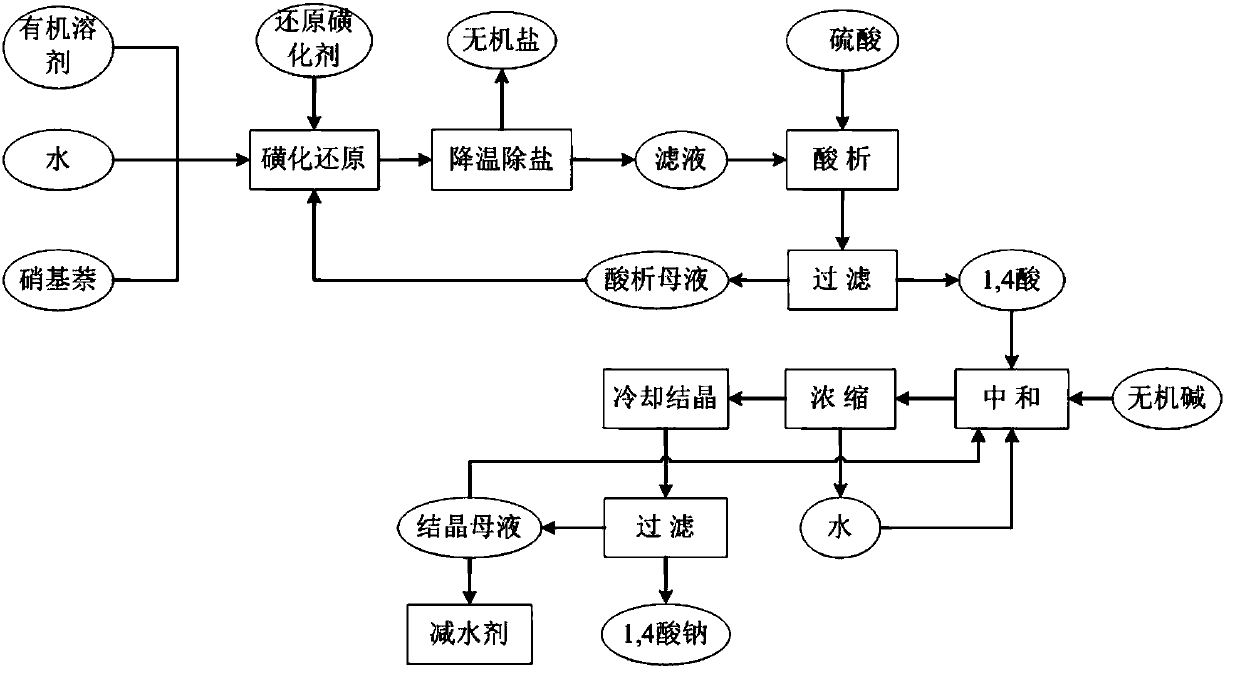

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing sodium 1-amino-4-naphthalenesulfonate, implemented according to the following steps:

[0030] (1) reduction sulfonation reaction: add bottom water 60g in reactor, then add N-N dimethylacetamide 60g, ethylene glycol 60g, 1-nitronaphthalene 17.3g, 16.42g sodium bisulfite successively, heat up to Reflux reaction at 108-114°C, and then add 4.47g of sodium bisulfite every 1h for a total of 5 times. After the feeding of sodium bisulfite is completed, react for 1h to the end of the reaction;

[0031] (2) Desalination: cool the material obtained in step (1) to 5°C, precipitate inorganic salts, then suction or pressure filter, collect filtrate 1, and filtrate 1 is used for acidification;

[0032] (3) Material acidification: add the filtrate 1 collected in step (2) into the reactor, heat up to 50-60° C., add 3.3 g of 98% sulfuric acid to adjust the pH of the filtrate to 1-2, then suction or pressure filter to collect the filter cake 2 and filtrate 2, the c...

Embodiment 2

[0036] A method for preparing sodium 1-amino-4-naphthalenesulfonate, implemented according to the following steps:

[0037](1) Reductive sulfonation reaction: Add 240g bottom water to the reactor, then add 120g1-methyl-2-pyrrolidone, 120g ethylene glycol, 69.2g1-nitronaphthalene, 59.38g sodium metabisulfite, and heat up to 108- Reflux reaction at 114°C, and then put in 19.8g of sodium metabisulfite every 1h for a total of 5 times, after the feeding of sodium metabisulfite is completed, react for 1h to the end of the reaction;

[0038] (2) Desalination: cool the material obtained in step (1) to 5°C, precipitate inorganic salts, then suction or pressure filter, collect filtrate 1, and filtrate 1 is used for acidification;

[0039] (3) Material acidification: add the filtrate 1 collected in step (2) into the reactor, heat up to 50-60° C., add 13.4 g of 98% sulfuric acid to adjust the pH of the filtrate to 1-2, then suction or pressure filter to collect the filter cake 2 and filt...

Embodiment 3

[0043] A method for preparing sodium 1-amino-4-naphthalenesulfonate, implemented according to the following steps:

[0044] (1) Reductive sulfonation reaction: add 300g bottom water in the reactor, then add 150gN-N dimethylformamide, 150g ethylene glycol, 86.5g1-nitronaphthalene, 82.1g sodium bisulfite successively, heat up to Reflux reaction at 108-114°C, and then add 27.3g of sodium bisulfite every 1h for a total of 5 times. After the feeding of sodium bisulfite is completed, react for 1h to the end of the reaction;

[0045] (2) Desalination: cool the material obtained in step (1) to 5°C, precipitate inorganic salts, then suction or pressure filter, collect filtrate 1, and filtrate 1 is used for acidification;

[0046] (3) Material acidification: add the filtrate 1 collected in step (2) into the reactor, heat up to 50-60° C., add 16.5 g of 98% sulfuric acid to adjust the pH of the filtrate to 1-2, then suction or pressure filter to collect the filter cake 2 and filtrate 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com